Abstract

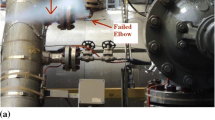

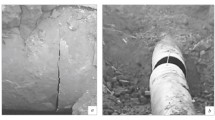

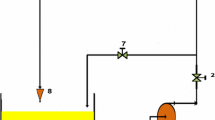

A steel-type ASTM A234 WPB elbow pipe from a gas well, through which water pressurized at 4 kg/cm2 and at 10–30 °C temperature was circulated, was perforated, originating a water leakage. Several tests were carried out in order to determine the cause of the perforation: Visual and radiographic inspection, chemical analysis, hardness test and microstructure, microscopy and fractographic studies. The presence of CO2 in the water might be very important for the corrosion phenomenon in the welding area as a result of the presence of a galvanic couple between the weld bead and the pipeline steel. However, the CO2 was not the only cause of the pipe damage. The fractographic study of the perforations and the flow analysis indicated that cavities have been originated as a consequence of a cavitation–corrosion phenomenon which is a particular erosion process caused by the implosion of gas bubbles on the metal surface.

Similar content being viewed by others

References

S.S.H. Abedi, A. Abdolmaleki, N. Adibi, Failure analysis of SCC and SRB induced cracking of a transmission oil products pipeline. Eng. Fail. Anal. 14(1), 250 (2007)

L. Aiju, W. Weiqiang, W. Xueming, Z. Dong, Fatigue and brittle fracture of carbon steel process pipeline. Eng. Fail. Anal. 12(4), 527 (2005)

T. Ping, Y. Jian, Z. Jinyang, W. Ieong, H. Shizheng, Y. Jianjun et al., Failure analysis and prediction of pipes due to the interaction between multiphase flow and structure. Eng. Fail. Anal. 16(5), 1749 (2009)

P. Cheng-hong, L. Zheng-yi, W. Xing-zhao, Failure analysis of a steel tube joint perforated by corrosion in a well-drilling pipe. Eng. Fail. Anal. 25, 13 (2012)

P.R. Roberge, Handbook of Corrosion Engineering, 2nd edn. (McGraw-Hill, New York, 2000)

M. Javidi, S. Bekhrad, Failure analysis of a wet gas pipeline due to localised CO2 corrosion. Eng. Fail. Anal. 89, 46 (2018)

L.T. Popoola, A.S. Grema, G.K. Latinwo, B. Gutti, A.D.S. Balogun, Corrosion problems during oil and gas production and its mitigation. Int. J. Ind. Chem. 4, 35 (2013)

M.B. Kermani, L.M. Smith, CO2 corrosion control in oil and gas production: design considerations, in The Institute of Materials (European Federation of Corrosion Publications, London, 1997)

E.-N. Yang, C.-M. Fu, C. Dong, S. Qu, J.-F. Tian, Z.-F. Zhang, Failure analysis of a leaked oil pipeline. Case Stud. Eng. Fail. Anal. 4, 88 (2015)

L. Giourntas, T. Hodgkiess, A.M. Galloway, Comparative study of erosion–corrosion performance on a range of stainless steels. Wear 46, 1051 (2015)

W. Glaeser, I.G. Wright, Forms of Mechanically Assisted Degradation, Corrosion: Fundamentals, Testing, and Protection, vol. 13A (ASM Handbook, ASM International, Cleveland, 2003), pp. 322–330

P.A. Schweitzer, Fundamentals of metallic corrosion: atmospheric and media corrosion of metals, in Corrosion Engineering Handbook, 2nd ed. (CRC Press, 2007)

J. M. Pintado, Fallo en servicio de los materiales metálicos. 1 ed (Instituto Nacional de Técnica Aeroespacial, 1992). pp. 392

Cavitation erosion and water drop impingement. ASM Handbook Vol 13-Corrosion, (1992) pp. 303

ASTM A 234/A 234M-02. Standard specification four piping fittings of wrought carbon steel and alloy steel for moderate and high temperature service

J.G. Liu, W.L.B.K. DaShi, Z.L. Li, Y.Z. Xu, W.R. Ji, C. Zhang, G. Cui, R.Y. Zhang, Effect of flow velocity on erosion–corrosion of 90-degree horizontal elbow. Wear 376–377(Part A), 516 (2017)

Y. Zhao, F. Zhou, J. Yao et al., Erosion–corrosion behavior and corrosion resistance of AISI 316 stainless steel in flow jet impingement. Wear 328–329, 464 (2015)

Practices in Failure Analysis, ASM Handbook Vol 11-Failure Analysis and Prevention (2002) pp. 850

Acknowledgments

Authors want to thank all Metallic Materials Area staff, especially the Microanalytical and Microstructural Characterization Laboratory. This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

García-Martínez, M., Valles González, M.P., González Meije, A. et al. Failure Analysis of a Steel Elbow Pipe from a Gas Well. J Fail. Anal. and Preven. 20, 723–733 (2020). https://doi.org/10.1007/s11668-020-00870-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00870-5