Abstract

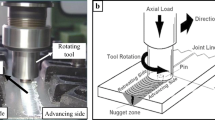

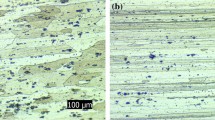

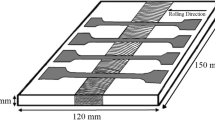

The heat treatment of friction stir tailor-welded aluminum joints is one important key process to improve the efficiency of joint strength and ductility as well as fracture locations, since almost all of the welded parts are subjected to a forming process. Therefore, the effect of heat treatment on microstructural characterization and mechanical properties of welded joints is a very important research area to improve the nugget zone in welded structures of aircraft segments. The objective of this study is to investigate the effect of changing pre-weld heat treatment conditions (first case: solution heat treated with artificial aging (T6) and second case: annealed heat treatment (O)) by microstructural characterization with an optical microscope, scanning electron microscope and x-ray diffraction and mechanical properties using micro-hardness, tensile and bending tests. After that, ANOVA was used in order to determine the interaction effect between the conditions of heat treatment (T6 and O) and interlayer strip widths. The results revealed that the softened zone of FSW joints in the annealed condition (O) was relatively more homogeneous than FSW joints from solution heat treated and artificially aged (T6). On the other hand, the strength efficiency of FSW joints from annealed (O) samples was the higher value than the joints efficiency at solution heat treated and artificially aged (T6). Furthermore, the annealed (O) FSW joints fractured in the base metal, while FSW joints from solution heat treated and artificially aged (T6) samples fractured in the HAZ. The microstructure and mechanical properties of weld nugget zones were influenced by the pre-weld heat treatment conditions. Finally, the results of ANOVA agreed with the results of mechanical properties.

Similar content being viewed by others

References

Z. Kailun, J. Denis, W. Liliang et al., A review on forming techniques for manufacturing lightweight complex-shaped aluminum panel components. Int. J. Lightweight Mater. Manuf. 1, 55–80 (2018)

Y. Morishita, Y. Sakamoto, F. Yoshida, Role of counter punch for square cup drawing of tailored blank composed of thick/thin sheets. J. Mater. Process. Technol. 212(10), 2102–2108 (2012)

R. Mishra, Y. Ma, Friction stir welding and processing. J. Mater. Sci. Eng: R Rep. 50(1–2), 1–78 (2005)

M. Abu-Okail, M.H. Ata, A. Abu-Oqail et al., Production of tailor-welded blanks by vertical compensation friction stir welding technique. J. Mater. Sci. Technol. 34(16), 2030–2041 (2018)

M. Abu-Okail, M.H. Ata, Enhancement ductility of friction stir welded aluminum blanks AA2024 via adding interlayer strip width of AA7075. J. Mater. Res. Express (2019). https://doi.org/10.1088/2053-1591/ab448c

M. Abu-Okail, M.H. Ata, A. Abu-Oqail, Effect of friction stir welding process parameters with interlayer strip on microstructural characterization and mechanical properties. J. Fail. Anal. Prev. 20(1), 173–183 (2019)

L. Zhang, S. Ji, G. Luan et al., Friction stir welding of Al alloy thin plate by rotational tool without pin. J. Mater. Sci. Technol. 27(7), 647–652 (2011)

R. Nandan, T. DebRoy, H. Bhadeshia, Recent advances in friction-stir welding–process, weldment structure and properties. Prog. Mater. Sci. 53(6), 980–1023 (2008)

J. Guo, H. Chen, C. Sun et al., Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater. Des. 56, 185–192 (2014)

T. Amancio-Filho, S. Sheikhi, J.F. Dos Santos et al., Preliminary study on the microstructure and mechanical properties of dissimilar friction stir welds in aircraft aluminum alloys 2024-T351 and 6056-T4. J. Mater. Process. Technol. 206(1–3), 132–142 (2008)

M. Cabibbo, A. Forcellese, M. Simoncini et al., Effect of welding motion and pre-/post-annealing of friction stir welded AA5754 joints. J. Mater. Des. 93, 146–159 (2016)

Z. Hu, S.J. Yuan, X.S. Wang et al., Effect of post-weld heat treatment on the microstructure and plastic deformation behavior of friction stir welded 2024. Mater. Des. 32(10), 5055–5060 (2011)

M. Imam, K. Biswas, V. Racherla, On use of weld zone temperatures for online monitoring of weld quality in friction stir welding of naturally aged aluminium alloys. Mater. Des. 52, 730–739 (2013)

J. Yan, A.P. Reynolds, Effect of initial base metal temper on mechanical properties in AA7050 friction stir welds. Sci. Technol. Weld. Join. 14(4), 282–287 (2009)

Y. Chen, H. Liu, J. Feng, Friction stir welding characteristics of different heat-treated-state 2219 aluminum alloy plates. Mater. Sci. Eng. A 420, 21–25 (2006)

V. Dixit, R.S. Mishra, R.J. Lederich et al., Effect of initial temper on mechanical properties of friction stir welded Al-2024 alloy. Sci. Technol. Weld. Join. 12(4), 334–340 (2007)

H. Aydin, A. Bayram, A. Uğuz et al., Tensile properties of friction stir welded joints of 2024 aluminum alloys in different heat-treated-state. Mater. Des. 30, 2211–2221 (2009)

Y.S. Sato, M. Urata, H. Kokawa, Parameters controlling microstructure and hardness during friction-stir welding of precipitation-hardenable aluminum alloy 6063. Metall. Mater. Trans. A 33, 625–635 (2002)

C.A. Widener, D.A. Burford, B. Kumar, J.E. Talia, B. Tweedy, Evaluation of post-weld heat treatments to restore the corrosion resistance of friction stir welded aluminum alloy 7075-T73 vs. 7075-T6. Mater. Sci. Forum 539–543, 3781–3788 (2007)

S. Sato, H. Kokawa, Distribution of tensile property and microstructure in friction stir weld of 6063 aluminum. Metall. Mater. Trans. A 32, 3023–3031 (2001)

M Abu–Okail, W Shewakh, A Brisha, Y Abdelraouf, A Abu-Oqail. Effect of GNPs content at various compaction pressures and sintering temperatures on the mechanical and electrical properties of hybrid Cu/Al2O3/xGNPs nanocomposites synthesized by high energy ball milling. Ceram. Int. (2020) (in press)

M. Abu-Okail, T.S. Mahmoud, A. Abu-Oqail, Improving microstructural and mechanical properties of AA2024 base metal by adding reinforced strip width of AA7075 via vertical compensation friction stir welding technique. J. Fail. Anal. Prev. 20(1), 184–196 (2019)

Acknowledgments

The authors are thankful to Helwan Company for Non-Ferrous Industries for providing the base material and compensation material for this research work and Helwan Engineering Industries Company for converting the milling machine to friction stir welding machine.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abu-Okail, M., Sabry, I., Abu-Oqail, A. et al. Effect of Changing Heat Treatment Conditions on Microstructural and Mechanical Properties of Friction Stir Welded Sheets of AA2024 with Interlayer Strip Width AA7075. J Fail. Anal. and Preven. 20, 701–722 (2020). https://doi.org/10.1007/s11668-020-00868-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00868-z