Abstract

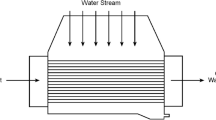

Failure analysis of a tubular oil heat exchanger made up of admiralty brass in an industrial unit was investigated. In the oil exchanger, circulating water is used as a coolant inside the brass tubes to reduce the temperature of oil flowing inside the brass shell. The causes of failure of the leaked admiral tubes were investigated performing various visual and microscopic examinations. Chemical analysis of the corrosion scales and its phase analysis with x-ray diffraction and microstructural examinations by optical and scanning electron microscopy were carried out. The study revealed that tube material was suffering from extensive de-zincification and under-deposit pitting.

Similar content being viewed by others

References

R.K. Shah, D.P. Sekulic, Fundamentals of Heat Exchanger Design, 1st edn. (John Wiley & Sons, New Jersey, 2003)

A.L.H. Costa, E.M. Queiroz, Design optimization of shell-and-tube heat exchangers. Appl. Therm. Eng. 28(14–15), 1798–1805 (2008)

V.K. Patel, R.V. Rao, Design optimization of shell-and-tube heat exchanger using particle swarm optimization technique. Appl. Therm. Eng. 30(11–12), 1417–1425 (2010)

E.A.D. Saunders, Heat Exchangers: Selection, Design & Construction, 1st edn. (Longman Scientific & Technical, New York, 1988)

Corrosion. ASM handbook, vol. 13. USA: ASM International; 1992

K. Rabindranath, N. Tanoli, H. Gopal, Failure investigation of brass heat exchanger tube. Eng. Fail. Anal. 26, 332–336 (2012)

R.K. Dinnappa, S.M. Mayanna, The dezincification of brass and its inhibition in acidic chloride and sulphate solutions. Corros. Sci. 27(4), 349–369 (1987)

H. Lu, K. Gao, W. Chu, Determination of tensile stress induced by dezincification layer during corrosion for brass. Corros. Sci. 40(10), 1663–1670 (1998)

A.S. El-Amoush, A. Zamil, D. Jaber, N. Ismail, Stress corrosion cracking of the pre-immersed tin brass heat exchanger tube in an ammoniacal solution. Mater. Des. 56, 842–847 (2014)

S. Qu, G. Yao, J.F. Tian, Z.F. Zhang, Failure analysis of the brass tubes in a lubricating oil cooler. Eng. Fail. Anal. 18(8), 2232–2239 (2011)

K. Ranjbar, Effect of flow induced corrosion and erosion on failure of a tubular heat exchanger. Mater. Des. 31(1), 613–619 (2010)

W.E. Heaton, Impingement corrosion of condenser tubes. Br. Corros. J. 12(1), 15–23 (1977)

U. Klein, A. Zunkel, A. Eberle, Breakdown of heat exchangers due to erosion corrosion and fretting caused by inappropriate operating conditions. Eng. Fail. Anal. 43, 271–280 (2014)

Z. Xia, Z. Szklarska-Smialowska, Pitting of admiralty brass. Corrosion 46(1), 85–88 (1990)

A. Vazdirvanidis, S. Papadopoulou, S. Papaefthymiou, G. Pantazopoulos, D. Skarmoutsos, Copper tubing failure due to ant-nest corrosion. In MATEC Web of Conferences, ICEAF 2018-5th International Conference of Engineering Against Failure, June 20–22 Chios Island, Greece

T.S. Rao, K.V.K. Nair, Microbiologically influenced stress corrosion cracking failure of admiralty brass condenser tubes in a nuclear power plant cooled by freshwater. Corros. Sci. 39(11), 1821–1836 (1998)

H. Han, Y.L. He, W.Q. Tao, Y.S. Li, A parameter study of tube bundle heat exchangers for fouling rate reduction. Int. J. Heat Mass Transfer 72, 210–221 (2014)

E. Sarver, M. Edwards, Effects of flow, brass location, tube materials and temperature on corrosion of brass plumbing devices. Corros. Sci. 53(5), 1813–1824 (2011)

R. Taherzadeh Mousavian, E. Hajjari, D. Ghasemi, M. Kojouri Manesh, K. Ranjbar, Failure analysis of a shell and tube oil cooler. Eng. Fail. Anal. 18(1), 202–211 (2011)

E.R. Weishaupt, M.E. Stevenson, J.L. McDougall, D.A. Turnquist, Case study: corrosion failure of yellow brass tubing in radiator application. J. Fail. Anal. And Preven. 12(3), 242–247 (2012)

R. Karpagavalli, R. Balasubramaniam, Development of novel brasses to resist dezincification. Corros. Sci. 49(3), 963–979 (2007)

Acknowledgments

The authors highly appreciate the financial support (Grant No. SCU.EM98.322) provided by Shahid Chamran University of Ahvaz, Iran.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ranjbar, K., Taghavian, A. & Amra, M. Failure Assessment of an Admiralty Brass Oil Exchanger Tubes. J Fail. Anal. and Preven. 20, 218–225 (2020). https://doi.org/10.1007/s11668-020-00823-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00823-y