Abstract

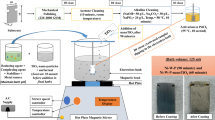

Bismaleimide (BMI) coating with and without aluminum oxide (Al2O3), silica oxide (SiO2), hexagonal boron nitride (h-BN), or organophilic montmorillonite clay 30B (OMMT) fillers on 1018 steel substrates was studied. Bilayer coatings consisting of BMI with one of the fillers at 5 wt.% for the first layer and pure BMI for the second layer were applied on 1018 steel substrates. The corrosion resistance of all coated samples was investigated through potentiodynamic polarization by using Tafel method in 4.2 wt.% sea salt solution. The results of the test showed that pure BMI coating improved the corrosion resistance by reducing the corrosion rate by 88%. Addition of 5 wt.% of OMMT or SiO2 fillers increased the efficiency of the coating in reducing corrosion rate by 99 and 97%, respectively. Adding 5 wt.% h-BN showed marginal improvements in the reduction in corrosion rates (89%). Addition of 5 wt.% Al2O3 as a filler dropped the efficiency of BMI coating to 64%. Adhesion of the coated steel was also affected depending on the filler type. Micro-hardness measurements using Vickers scale were taken to assess coating hardness, and scanning electron microscopy was used to investigate the dispersion of filler particles in the matrix.

Similar content being viewed by others

References

W.D. Callister, J.D.G. Rethwisch, Fundamentals of Materials Science and Engineering, 3rd edn. (Wiley, New York, 2007)

D.A. Jones, Principles and Prevention of Corrosion, 2nd edn. (Prentice Hall, Upper Saddle River, 1996)

M.G. Fontana, Corrosion Engineering, 3rd edn. (McGraw-Hill, Singapore, 1986)

R. Rihan, R. Shawabkeh, N. Al-Bakr, The effect of two amine-based corrosion inhibitors in improving the corrosion resistance of carbon steel in sea water. J. Mater. Eng. Perform. 23, 693–699 (2014)

S. Park, M. Shon, Effects of multi-walled carbon nano tubes on corrosion protection of zinc rich epoxy resin coating. J. Ind. Chem. 21, 1258–1264 (2015)

R. Hasanov, S. Bilgic, Monolayer and bilayer conducting polymer coatings for corrosion protection of steel in 1 M H2SO4 solution. Prog. Org. Coat. 64, 435–445 (2009)

M. Behazdnasab, S.M. Mirabedini, M. Esfandeh, Corrosion protection of steel by epoxy nanocomposite coatings containing various combinations of clay and nanoparticulate zirconia. Corr. Sci. 75, 134–141 (2013)

A.H. Navarchain, M. Joulazadeh, F. Karimi, Investigation of corrosion protection performance of epoxy coatings modified by polyaniline/clay nanocomposites on steel surfaces. Prog. Org. Coat. 77, 347–353 (2014)

H. Jeon, J. Park, M. Shon, Corrosion protection by epoxy coating containing multi-walled carbon nanotubes. J. Ind. Eng. Chem. 19, 849–853 (2013)

M. Mobin, N. Tanveer, Corrosion performance of chemically polymerized poly (pyrrole_co_o_toluidine) coating on mild steel. Prot. Met. Phys. Chem. Surf. 48, 243–250 (2012)

D. Yuhua, M. Liqin, Z. Qiong, Effect of the incorporation of montmorillonite-layered double hydroxide nanoclays on the corrosion protection of epoxy coatings. J. Coat. Technol. Res. 10, 909–921 (2013)

E. Martin, M. Attar, B. Ramezanzadeh, Investigation of corrosion protection properties of an epoxy nanocomposite loaded with polysiloxane surface modified nanosilica particles on the steel substrate. Prog. Org. Coat. 78, 395–403 (2015)

B.P. Singh, B.K. Jena, S. Bahttacharjee, L. Besra, Development of oxidation and corrosion resistance hydrophobic graphene oxide-polymer composite coating on copper. Surf. Coat. Technol. 232, 475–481 (2013)

L.G. Eccoa, J. Lib, M. Fedela, F. Defloriana, J. Pan, EIS and in situ AFM study of barrier property and stability of waterborne and solventborne clear coats. Prog. Org. Coat. 77, 600–608 (2014)

C.K. Tan, D.J. Blackwood, Corrosion protection by multilayered conducting polymer coatings. Corros. Sci. 45, 545–557 (2003)

N. Elhalawany, M.A. Mossad, M.K. Zahran, Novel water based coatings containing some conducting polymers nanoparticles (CPNs) as corrosion inhibitors. Prog. Org. Coat. 77, 725–732 (2014)

I. Díaz, B. Chico, D. de la Fuente, J. Simancas, J.M. Vega, M. Morcillo, Corrosion resistance of new epoxy–siloxane hybrid coatings. A laboratory study. Prog. Org. Coat. 69, 278–286 (2010)

A. Talo, O. Forsen, S. Ylasaari, Corrosion protective polyaniline epoxy blend coatings on mild steel. Synth. Met. 102, 1394–1395 (1999)

M.K. Madhup, N.K. Shan, P.M. Wadhwai, Investigation of surface morphology, anti-corrosive and abrasion resistance properties of nickel oxide epoxy nanocomposite (NiO-ENC)coating on mild steel substrate. Prog. Org. Coat. 80, 1–10 (2015)

A.M.T. Huerta, M.A.D. Crespo, A.A. Valdelamar, E.O. Bustamante, M.L. Escudero, M.C.G. Alonso, J.A.L. Correa, Role of preparation method on the microstructure and mechanical properties of PPy/Ni organic–inorganic hybrid bilayer coatings on carbon steel. Metall. Mater. Trans. A 46, 1741–1755 (2015)

R. Ansari, A.H. Alikhani, Application of polyaniline/nylon composites coating for corrosion protection of steel. J. Coat. Technol. Res. 6, 221–227 (2009)

W.C. Chiou, J.L. Han, S.N. Lee, Synthesis and studies of the physical properties of polyaniline and polyurethane-modified epoxy composites. Poly. Eng. Sci. 10, 345–354 (2008)

T.T.X. Hang, T.A. Truc, T.H. Nam, V.K. Oanh, J.B. Jorcin, N. Pebere, Corrosion protection of carbon steel by an epoxy resin containing organically modified clay. Surf. Coat. Technol. 201, 7408–7415 (2007)

T.T.X. Hang, T.A. Truc, M.G. Olivier, C. Vandermiers, N. Guerit, N. Pebere, Corrosion protection mechanisms of carbon steel by an epoxy resin containing indole-3 butyric acid modified clay. Prog. Org. Coat. 69, 410–416 (2010)

M.J. Palimi, M. Peymannia, B. Ramezanzadeh, An evaluation of the anticorrosion properties of the spinel nanopigment-filled epoxy composite coatings applied on the steel surface. Prog. Org. Coat. 80, 164–175 (2015)

A.G. Kahrizsangi, H. Shariatpanahi, J. Neshati, E. Akbarinezhad, Corrosion behavior of modified nano carbon black/epoxy coating in accelerated conditions. Appl. Surf. Sci. 331, 115–126 (2015)

M. Conradi, A. Cocijan, M. Zorko, I. Verpoest, Damage resistance and anticorrosion properties of nanosilica-filled epoxy-resin composite coatings. Prog. Org. Coat. 80, 20–26 (2015)

W. Tian, F. Meng, L. Liu, Y. Li, F. Wang, The failure behaviour of a commercial highly pigmented epoxy coating under marine alternating hydrostatic pressure. Prog. Org. Coat. 82, 101–112 (2015)

M. Bucko, V.M. Stankovic, J. Rogan, J.B. Bajat, The protective properties of epoxy coating electrodeposited on Zn–Mn alloy substrate. Prog. Org. Coat. 79, 8–16 (2015)

S. Cecciaa, E.A. Turcatoa, P.L. Maffettoneb, R. Bongiovannia, Nanocomposite UV-cured coatings: organoclay intercalation by an epoxy resin. Prog. Org. Coat. 63, 110–115 (2008)

Y.C. Huang, T.Y. Lo, C.G. Chao, W.T. Whang, Anti-corrosion characteristics of polyimide/h-boron nitride composite films with different polymer configurations. Surf. Coat. Technol. 260, 113–117 (2014)

T.C. Huang, C.F. Hsieh, T.C. Yeh, C.L. Lai, M.H. Tsai, J.M. Yeh, Comparative studies on corrosion protection properties of polyimide-silica and polyimide-clay composite materials. J. Appl. Polym. Sci. 119, 258–557 (2011)

T.C. Huang, Y.A. Sua, T.C. Yeha, H.Y. Huanga, C.P. Wua, K.Y. Huangb, Y.C. Chouc, J.M. Yeha, Y. Weid, Advanced anticorrosive coatings prepared from electroactive epoxy–SiO2 hybrid nanocomposite materials. Electrochim. Acta 56, 6142–6149 (2011)

T.C. Huang, T.C. Yeh, H.Y. Huang, W.F. Ji, T.C. Lin, C.A. Chen, T.I. Yang, J.M. Yeh, Electrochemical investigations of the anticorrosive and electrochromic properties of electroactive polyamide. Electrochim. Acta 63, 185–191 (2012)

K. Saravanan, S. Sathiyanaryanan, S. Muralidharan, S. Syed Azim, G. Venkatachari, Performance evaluation of polyaniline pigmented epoxy coating for corrosion protection of steel in concrete environment. Prog. Org. Coat. 59, 160–167 (2007)

M. Mandhakini, T. Lakshmikandhan, A. Chandramohan, M. Alagar, Effect of nanoalumina on the tribology performance of C4-ether-linked bismaleimide-toughened epoxy nanocomposites. Tribol. Lett. 54, 67–79 (2014)

X. Zhang, J.P. Bell, Synthesis of protective coatings on steel by surface spontaneous polymerization. 3: process development and coating property studies. Polym. Eng. Sci. 39, 119–127 (1999)

F.T. Cheng, H.C. Man, W.M. Chan, C.W. Cheng, W.O. Chan, Corrosion protection of Nd–Fe–B magnets by bismaleimide coating. J. Appl. Phys. 85, 5690–5692 (1999)

Y. Nakayama, High performance coating films cured by novel penetrating method: anionic resin paints. J. Coat. Technol. 69, 61–67 (1997)

C. Qunfenga, F. Zhengpinga, X. Yahongb, Y.X. Sub, Morphological and spatial effects on toughness and impact damage resistance of PAEK-toughened BMI and graphite fiber composite laminates. Chin. J. Aeronaut. 22, 87–96 (2009)

P. Sun, Y. Zhao, Y. Luo, L. Sun, Effect of temperature and cyclic hygrothermal aging on the interlaminar shear strength of carbon fiber/bismaleimide (BMI) composite. Mater. Des. 32, 4341–4347 (2011)

Lake Products Company LLC-ASTM D 1141

ASTM G5, Standard reference test method for making potentiodynamic anodic polarization measurements

ASTM G59, Standard test method for conducting potentiodynamic polarization resistance measurements

ASTM D4541, Standard test method for pull-off strength of coatings using portable adhesion testers

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al Shenawa, A., Nasrazadani, S. & D’Souza, N.A. Effects of Filler Type in Bismaleimide Matrix on Corrosion Resistance of Steel in Sea Salt. J Fail. Anal. and Preven. 20, 145–152 (2020). https://doi.org/10.1007/s11668-020-00810-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00810-3