Abstract

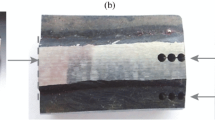

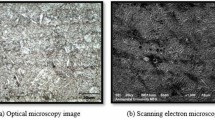

As the main component of barrel weapon, the wear of barrel is a key factor of its service life. In this study, the typical barrel material is selected as the research object. Firstly, through theoretical analysis, the contact stress on the barrel inner wall generated by the extrusion of projectile is obtained. According to the calculation result, the load parameters of the wear test are determined. Then, the high-temperature wear tester is used to study the wear properties of the chrome-plated steel with different matrix hardness at high temperature. Finally, the wear scar profile, the wear surface, the cross section and the subsurface hardness have been analyzed. The test results show that the failure mechanism of high-temperature wear of chrome-plated steel with different matrix hardness is different. By increasing the hardness of the matrix, the high-temperature wear resistance of gun barrel material can be improved.

Similar content being viewed by others

References

J.H. Underwood, G.N. Vigilante, C.P. Mulligan et al., Thermomechanically controlled erosion in Army cannons: a review. J. Pressure Vessel Technol. 128(2), 168–172 (2006)

J.H. Underwood, E. Troiano, Critical fracture processes in army cannons: a review. J. Pressure Vessel Technol. 125(3), 287–292 (2003)

J.H. Underwood, A.P. Parker, G.N. Vigilante et al., Thermal damage, cracking and rapid erosion of cannon bore coatings. J. Pressure Vessel Technol. 125(3), 299 (2003)

J.H. Underwood, G.N. Vigilante, C.P. Mulligan, Review of thermo-mechanical cracking and wear mechanisms in large caliber guns. Wear 263(7–12), 1616–1621 (2007)

G.X. Zhang, G.N. Chen, K. Zhang et al., Mechanical mechanism study on prolonging life of chromium-plated gun bore through laser discrete pretreatment. Binggong Xuebao/Acta Armamentarii 27(6), 978–983 (2006)

H.T. Fu, J. Zhang, J.F. Huang et al., Comparison of nitrided hot work tool steel and chromium coated 30SiMn2MoVA. China Surf. Eng. 28(6), 1 (2015)

B.Q. Yang, K. Zhang, G.N. Chen et al., A quantitative analysis of the effect of laser transformation hardening on crack driving force in steels. Surf. Coat. Technol. 201(6), 2208–2216 (2006)

B.Q. Yang, K. Zhang, G.N. Chen et al., Effect of a laser pre-quenched steel matrix surface on the crack driving force in a coating–steel matrix system. Acta Mater. 55(13), 4349–4358 (2007)

R.S. Montgomery, Friction and wear at high sliding speeds. Wear 36(3), 275–298 (1976)

R.S. Montgomery, The sliding behaviors of copper alloys. Wear 87(3), 339–349 (1983)

R.S. Montgomery, Wear of projectile rotating bands. Wear 101(4), 347–356 (1985)

Y. Chen, Q. Song, J. Wang, New technologies to extend the erosion life of gun barrel. Acta Armamentarii 27(2), 330–334 (2006)

C.M. Walsh, C.D. Knott, C.S. Leveritt, Reduced erosion additive for a propelling charge: U.S. Patent 6,984,275. 2006-1-10

J.K. Hirvonen, J.D. Demaree, D.K. Marble et al., Gun barrel erosion studies utilizing ion beams. Surf. Coat. Technol. 196(1–3), 167–171 (2005)

H.X. Gao, J.F. Huang, J.S. Zhang et al., Formation and spalling off mechanism of white layer of rapid-firing gun steel. Heat Treat. Met. 33(10), 109–113 (2008)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Zang, Y., Zhang, J. et al. Failure Analysis of High-Temperature Wear Mechanism of Chromium-Plated Steel with Different Matrix Hardness. J Fail. Anal. and Preven. 19, 1370–1379 (2019). https://doi.org/10.1007/s11668-019-00734-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00734-7