Abstract

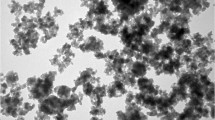

Rowing, or crew, is a constantly evolving sport with an impressive history of equipment advancements, including the use of advanced polymer matrix composites as construction materials for boats and oars. While the use of composites undoubtedly improves the performance of the equipment, the complexity of such a material makes it difficult to establish the cause of failures observed during practice and competition. In particular, composite oars, which are ubiquitous in competitive rowing, have the potential for catastrophic failure. The present effort at investigating the failure mechanisms of a composite oar involved metallographic examinations of the fracture surface using a scanning electron microscope (SEM)/energy-dispersive X-ray spectroscopy (EDS), as well as finite element stress analyses using ANSYS software. From a cross section analysis, the fiber volume percentage of the oar was measured to be 58.2%. Finite element modelling results suggested that oar failure was not the result of a discrete load, which implies that cyclic loading and structural defects were likely the primary contributing factors. A visual fracture analysis revealed surface defects introduced due to improper handling. No chemical degradation was found in the vicinity of the fracture site; however, degradation in the form of congelifraction (freeze–thaw of trapped water) was found to be a possibility. Based on the aggregate results of this investigation, recommendations for suppliers are provided in terms of manufacturing process and for sporting organizations at large with respect to improved storage and transportation of oars to reduce the likelihood of fatigue failures during training and competitions.

Similar content being viewed by others

References

K. Affeld, K. Schichl, A. Ziemann, Assessment of rowing efficiency. J. Sports Med. 14, 39–41 (1993)

A. Coppel, T.N. Gardner, N. Caplan et al., Simulating the fluid dynamic behvaiour of oar paddles in competition rowing. J. Sports Eng. Technol. 224, 25–35 (2010)

M. Hofmijster, E. Landman, R. Smith, Effect of Stroke Rate on the Distribution of Mechanical Power in Rowing. J. Sports Sci. 25, 403–411 (2006)

D. Hawkins, A new instrumentation system for training rowers. J. Biomech. 33, 241–245 (1998)

N. Secher, Physiological and biomechanical aspects of rowing. J. Sports Med. 15, 24–42 (1993)

P. Pudlo, F. Barbier, J.C. Angue, Instrumentation of the concept II ergometer for optimization of the gesture of the rower, in The Engineering of Sport, 1st edn., ed. by S. Haake (A.A. Balkema, Rotterdam, 1996), pp. 137–146

K. Pilgeram, M.J. Delwiche, Device for on-the-water measurement of rowing ouput. J. Sports Eng. Technol. 9, 165–174 (2006)

A. Millward, A study of the forces exerted by an oarsman and the effect on boat speed. J. Sports Sci. 5, 90–103 (1987)

F. Breitschadel, Vibration analyses of single scull oars. Procedia Engineering 2, 3011–3016 (2010)

Concept2. Quality Control and Testing. http://www.concept2.com/oars/how-made-and-tested/quality-control. Accessed Augt 2014

M. Masuelli, Introduction of fibre-reinforced polymers—polymers and composites: concepts, properties and processes., in Fibre Reinforced Polymers—The Technology Applied for Concrete Repair. Epub ahead of print 23 January 2013. https://doi.org/10.5772/54629

D. Roylance, Laminated Composite Plates. Report, Massachusetts Institute of Technology, Cambridge USA 2000

J. Rouchon, in Fatigue and Damage Tolerance Evaluation of Structures: The Composite Materials Response. Report for the National Aerospace Laboratory. Report no. NLR-TP-2009-221, May 2009

Concept2. Checking and Setting Oar Length. http://www.concept2.com/service/oars/checking-and-setting-oar-length. Accessed Aug 2014

Creaform. Technical Specifications: Handyscan 3D Handheld 3D Scanner. http://www.creaform3d.com/en/Metrology-solution/products/portable-3d-scanner/technical-specifications-handyscan-3d. Accessed Aug 2014

Tescan. Vega3 XM. http://www.tescan.com/en/products/vega-sem/vega3-xm. Accessed Aug 2014

Seal Laboratories. How SEM-EDS Works. http://www.seallabs.com/how-sem-eds-works.html. Accessed Aug 2014

AcpComposites. Product Specification Reference Sheet: Mechanical Properties of Carbon Fibre Composite Materials, Fibre/Epoxy resin (120 degree C cure). http://www.acpsales.com/upload/Mechanical-Properties-of-Carbon-Fiber-Composite-Materials.pdf. Accessed Aug 2014

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Erazo, F., Laliberte, J., Huang, X. et al. An Investigation of the Failure Mechanisms of a Polymer Matrix Composite Crew Oar. J Fail. Anal. and Preven. 19, 716–729 (2019). https://doi.org/10.1007/s11668-019-00651-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00651-9