Abstract

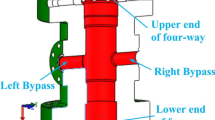

This paper presents a novel structure with reliable sealing property for the inner blowout preventer (BOP) device aiming at improving its safety and reliability during drilling process. Namely, the study of effects of flow rate and seat cone angle on the erosion wear rate of inner BOP is performed based on the numerical simulation analyses of inner flow field of inner BOP by means of computational fluid dynamics method with various models including RNG k–ε model, discrete phase model and Tabakoff–Grant erosion model. The finite volume method is used for the discrete calculation, and the SIMPLE algorithm is applied for solving the continuity, momentum, energy and turbulent kinetic energy equations. The results reveal that some positions of the valve core are prone to erosion wear, and the optimal angle of the taper angle of the upper and lower valve seats for the inner BOP is 25°. Finally, the static stress analyses and leak tests validate the reliability of the inner BOP. These analyses provide the basis for structural design of the inner BOP.

Similar content being viewed by others

References

Y.R. Luo, Y.Y. Tian, 钻井控制技术与设备 (Drilling well control technology and equipment). Pet. Mach. 8, 1–3 + 11–6 (2012). (in Chinese)

The Great Wall drilling well control training center, etc., 钻井井控技术与设备 (Drilling Well Control Technology and Equipment) (Petroleum Industry Press, Beijing, 2012), pp. 63–67 + 82–84. (in Chinese)

J. Xie, D.Y. Wang, Y.Q. Li, H. Chen, 钻柱内防喷工具的现状和研究方向建议 (Reflections on the present situation and research direction of drillstring inner blowout prevention tools). Mechanics 10(2), 4–6 (2007). (in Chinese)

H. Chen, C.J. Wang, Z. Wu, Y.B. Pei, Y.Y. Su, 安全钻井钻柱内防喷系统止回阀工作机理及失效分析 (Working Mechanism and failure analysis of check valve in safe drilling string inner blowout prevention system). Nat. Gas Ind. 30(6), 69–72 + 129–130 (2010). (in Chinese)

P.J. Roach, Computational Fluid Mechanics (Science Press, Beijing, 1983), pp. 5–11. (in English)

J.D. Anderson, Computational Fluid Dynamics. The Basics with Applications (Mechanical Industry Press, New York, 2007), pp. 5–11. (in English)

W. Jia, C. Yin. CFD simulation with fluent and experimental study on the characteristics of spool valve orifice, in ICCET 2010 International Conference on Computer Engineering and Technology, Proceedings, vol 1 (2010), pp. 173–177

Y.J. Xie, J.C. Fan, H. Zhang, 页岩气开发用高压管汇损伤机理及检测技术 (Mechanism and detection technique of high pressure pipe sink damage for shale gas development). Petr. Mach. 39(S1), 109–112 (2011). (in Chinese)

M. Dan, Numerical simulation about the effect rules of particles concentration on erosion of the centrifugal fan. Adv. Mater. Res. 594–597, 2162–2166 (2012)

B. Li, Q. Zhang, 基于 CFD 的螺杆钻具旁通阀冲蚀特性分析 (Analysis of erosion characteristics of screw drill bypass valve based on CFD). Coal Eng. 49(07), 132–135 (2017). (in Chinese)

X. Li, D.L. Gao, L.C. Tan, H. Zhang. Study on the drilling fluid flow rate allowable range in offshore drilling considering the extended-reach limit, in Abu Dhabi International Petroleum Exhibition and Conference, 13–16 Nov 2017

J.L. Zhu, M.L. Duan, T.Y. Ye, S.X. Xu, H.H. Tie, 水下采油树生产模块通道多相冲蚀数值分析 Numerical analysis of multiphase erosion of module channel in subsea production tree. Pet. Mach. 44(03), 58–62 (2016). (in Chinese)

H.Z. Jin, Y.W. Yi, X. Liu, H.J. Ye, J. Xu. Simulation and analysis of erosion characteristics in flushing oil pipeline with liquid-solid phase fluids. Oil-gas storage and transportation. Mocaxue Xuebao/Tribology, vol 36, no 6, pp. 695–702 1 Nov 2016. (in English)

H.B. Liu, H. Mou, 加砂压裂中固体支撑剂对压裂管道的冲蚀磨损研究 (Study on erosion and wear of fracturing pipeline by solid proppant in sand fracturing). Chin. Sci. Technol. Safe Prod. 14(01), 87–94 (2018). (in Chinese)

V. Balasoiu, I. Bordeasu, M.O. Popoviciu. The cavitation phenomenon in the flow zone distributor body spool valve, in Annals of DAAAM and Proceedings of the International DAAAM Symposium (2008), pp. 59–60

Z.J. Zheng, G.F. Ou, H.J. Ye, L.T. Zhang, C. Wang, Investigation on failure process and structural optimization of a high pressure letdown valve. Eng. Fail. Anal. 66, 223–239 (2016). (in English)

Q.Q. Lu, J.R. Fontaine, G. Aubertin, A Lagrangian model for solid particles in turbulent flows. Multiph. Flow 19(2), 347–367 (1993). (in English)

Y. Zhou, Z.Q. Zhang, Y. Bu, C.S. Qiu, Simulation studies on drilling mud pump plunger seal failure under ultrahigh pressure and ultradeep conditions. Eng. Fail. Anal. 45, 142–150 (2014). (in English)

J. Yan. 氮气钻井新型箭形止回阀结构分析与设计 (The Analysis and Design for New Structure of Arrow-Shape Check Valve Used in Nitrogen Drilling). (Southwest Petroleum University, 2013), pp. 53–54. (in Chinese)

Acknowledgments

The authors gratefully acknowledge the financial support from the Natural Science Foundation of China (Grant Number: 51222406).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiao-dong, Z., Long, C. Effect of the Spool Cone Angle on the Erosion of a Novel Inner Blowout Preventer. J Fail. Anal. and Preven. 19, 279–290 (2019). https://doi.org/10.1007/s11668-019-00608-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00608-y