Abstract

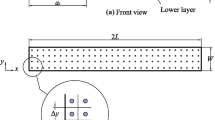

This research aims to study the delamination behaviors of T700/8911 composite laminates under hygrothermal environment. For two mixed-mode I/II delamination specimens: single-leg bending delamination and over-leg bending delamination, finite element analysis using virtual crack closure technique as a ABAQUS module is comparatively performed to study the delamination growth and load responses, in which different delamination growth criteria are used. Mechanical tests and analytical solutions for two kinds of specimens are used to get the delamination fracture toughness. Results show that hygrothermal environment decreases the load-bearing ability and delamination resistance to some extent. This work provides a new thread for studying the delamination mechanisms of composite laminates under hygrothermal environment.

Similar content being viewed by others

References

E.F. Rybicki, M.F. Kanninen, A finite element calculation of stress intensity factors by a modified crack closure integral. Eng. Fract. Mech. 9(4), 931–938 (1977)

M.L. Benzeggagh, M. Kenane, Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 56(4), 439–449 (1996)

E.M. Wu, R.C. Reuter, Crack extension in fiberglass reinforced plastics. Crack extension in fiberglass reinforced plastics (vol. 275). Illinois Univ Urbana Dept of Theoretical and Applied Mechanics (1965)

J. Reeder, S. Kyongchan, P.B. Chunchu, D.R. Ambur, Postbuckling and growth of delamination in composite plates subjected to axial compression, in 43rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Denver, Colorado (2002)

E.G. Wolff, Moisture effects on polymer matrix composites. SAMPE J. 29(3), 11–19 (1993)

M.L. Costa, Strength of hygrothermally conditioned polymer composites with voids. J. Compos. Mater. 39(21), 1943–1961 (2005)

J.M. Zhou, J.P. Lucas, Hygrothermal effects of epoxy resin. Part I: the nature of water in epoxy. Polymer 40(20), 5505–5512 (1999)

G.M. Cândido, M.L. Costa, M.C. Rezende, S.F.M. Almeida, Hygrothermal effects on quasi-isotropic carbon epoxy laminates with machined and molded edges. Compos. B Eng. 39(3), 490–496 (2008)

S.K. Singh, A. Chakrabrti, Hygrothermal analysis of laminated composites using a C0FE model based on RHSDT. Inter. J. Earth Sci. Eng. 4(6), 604–607 (2011)

A. Ghosh, Hygrothermal effects on the initiation and propagation of damage in composite shells. Aircr. Eng. Aeros. Technol. 80(4), 386–399 (2008)

R. Sullivan, A thermodynamic model for hygrothermal behavior in polymer composites, in 35th Structures, Structural Dynamics, and Materials Conference (1993)

A. Bahrami, A. Nosier, Interlaminar hygrothermal stresses in laminated plates. Inter. J. Solids Struct. 44(25), 8119–8142 (2007)

B.C. Ray, Temperature effect during humid ageing on interfaces of glass and carbon fibers reinforced epoxy composites. J. Colloid Interf. Sci. 298(1), 111–117 (2006)

L.R. Bao, A.F. Yee, Moisture diffusion and hygrothermal aging in bismaleimide matrix carbon fiber composites-part I: uni-weave composites. Compos. Sci. Technol. 62(16), 2099–2110 (2002)

P.F. Liu, Z.P. Gu, Finite element analysis of single-leg bending delamination of composite laminates using a nonlinear cohesive model. J. Fail. Anal. Prev. 15(6), 1–7 (2015)

P.F. Liu, J. Yang, B. Wang, Z.F. Zhou, J.Y. Zheng, A study on the intralaminar damage and interlaminar delamination of carbon fiber composite laminates under three-point bending using acoustic emission. J. Fail. Anal. Prev. 15(1), 101–121 (2015)

S.H. Yoonn, C.S. Hong, Modified end notched flexure specimen for mixed mode interlaminar fracture in laminated composites. Inter. J. Fract. 43(1), 3–9 (1990)

B.D. Davidson, V. Sundararaman, A single leg bending test for interfacial fracture toughness determination. Inter. J. Fract. 78(2), 193–210 (1996)

A. Szekrenyes, J. Uj, Over-leg bending test for mixed-mode I/II interlaminar fracture in composite laminates. Inter. J. Damage Mech. 16(1), 5–33 (2007)

Acknowledgments

Prof. Pengfei Liu would sincerely like to thank the National Key Fundamental Research and Development Project of China (No. 2015CB057603) and the National Natural Science Funding of China (No. 51875512).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J.G., Liu, P.F. & Chu, J.K. Finite Element Analysis of Delamination Behaviors of Composite Laminates under Hygrothermal Environment Using Virtual Crack Closure Technique. J Fail. Anal. and Preven. 19, 147–153 (2019). https://doi.org/10.1007/s11668-019-00582-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00582-5