Abstract

The present paper summarizes the experimental study of the mechanical behavior of high-density polyethylene structure welded by butt-welding process, subjected to tensile loading. In this work, we based on experimental tests in order to characterize the studied material, introducing the ductility and the fragility of the bead-welded section material, seeing the influence of the crosshead speed of 10 and 50 mm/min and taking into account the weld parameters such as the fusion temperature for a such given inner diameter. The welding parameters had a direct impact on microstructure of bead weld which itself is very heterogeneous.

Similar content being viewed by others

Introduction

The use of butt-welding is adopted as a process of assembling high-density polyethylene (HDPE) pipes of different diameters (Di) to transport gas or water, and this depends on the welding conditions.

In the literature, various authors like Costa et al. [1] have studied and proposed the classification of fusion consolidation of thermoplastic matrix composites and several studies have been carried out to study the simulation of large deformations in polymers.

Neale and Tugcu [2] carried out a FEM analysis of a cylindrical tensile test specimen and studied the deformation in high-density polyethylene (HDPE) thoroughly at the microscopic and macroscopic levels.

The total heating phase is made up of the matching phase and the pressure low heating phase. The matching force is a time-dependent parameter in the same way as the matching displacement and first increases steadily, then reaches a peak and finally falls to a constant value independent of time [3]. This force profile is a consequence of the fusion process and the frictional forces that develop in the machine butt-welding. If the force is integrated over the time and expressed in terms of the pipe’s area of cross section, then this will give the mean matching pressure PA. This is lower than the hydraulic pressure expressed in terms of the pipe’s area of cross section. In our cases, the difference amounted to roughly 10%. Since the frictional forces can differ very considerably in different machines, the matching force should be measured so that reproducible results can be obtained.

Zhang and Ben Jar [4] used a phenomenological hybrid approach based on experimental tests and FE simulations to model the deformation and ductile fracture of annular samples prepared from a commercial polymer tube and studied the effect of rate of change of damage on the deformation and rupture behavior of a sample of polymer pipe.

The main aim of this study is to compare and estimate the durability between two cases unwelded and welded specimens of HDPE by means of butt fusion procedure to know the physical quantities and the understanding of the effect of the deformation velocity on the mechanical behavior of the weld joint (bead) of a high-density polyethylene (HDPE) pipe welded by conditions proposed by us such as the melting temperature and the pressure force as defined in Table 1.

We performed two trials for each case and for the same stretching rates (Ve). The temperature of all the tests equals the ambient temperature (Ta = 23°); the ratio of the nominal dimensions SDR of the tubes (diameter and thickness) is constant. This constant is determined in the following form:

Experimental Work

Material Studied

The material used in this study is high-density polyethylene (HDPE). It is a semi-crystalline thermoplastic widely used in engineering applications such as pipelines and pressure vessels. In the literature, various studies [5, 6] and [7] have examined the microscopic structure and plastic deformation processes of thin films of high-density polyethylene HDPE, Fig. 1 shows the Observation of the formation of microstructural defects by SEM in HDPE [5]. The study material was manufactured in one time as granules, imported by the company STPM CHIALI located in Sidi Bel Abbes (ALGERIA) [8]. It was then extruded to make tubes of different diameters. The extrusion conditions are determined in order to ensure the most homogeneous cooling.

Observation of the formation of microstructural defects by SEM in HDPE [5]

The technical, physical and chemical specifications of the material studied are summarized in Table 2.

Welding Process

In practice, high-density polyethylene (HDPE) pipes also have the major advantage of being assembled by the fusion welding technique (butt-welding) efficient and easy to implement. To understand the mechanisms of weld formation, it is necessary to analyze in detail the butt-welding process.

Butt-welding is a technique for assembling thermoplastics by melting the ends of two tubular elements by means of a heating plate called a mirror. This process consists of melting the material at the surface to be welded (Fig. 2).

Formation of bead welding according to ASTM standard F2620-11 [9]

In general, there are four main steps for connecting the HDPE tubes by butt-welding:

-

I. Equalization: This step aims to ensure that the entire surface of the tube is in contact with the heating mirror.

-

II. Heating: This step aims to widen the molten polymer layer, necessary for welding. Heating ends when it considered that the thickness of molten polymer obtained is sufficient to form a weld of good quality.

-

III. Removing the mirror: The tubes are discarded from the mirror so that it can be removed. Its duration must be as short as possible to limit the flow and cooling of the molten polymer in contact with the ambient air.

-

IV. Welding: This is the last step in which the two tubes are pressed against each other with some pressure that is maintained until the weld solidifies. During this stage, the material flows laterally giving the final shape of the bead.

At the level of the welding plane resulting from the lateral ejection of the melt formed at the end of the tubes, the thickness of the melted layer alter matching is negligibly low and that the temperature gradient is very large; then, it is possible to calculate the thickness of the melt layer (Fig. 3) that forms during the pressure low heating phase with Eq 1. In this work, the type of welding proposed is characterized by the appearance of a bead [3].

Universal Equation

Special Equation

Material: HDPE, Hostalen GM 5010 T2

TK—crystallization temperature; TG—interface temperature, η—viscosity for δ = 10 s−1.

Scale Up Rules

Uniaxial Tensile Tests Specimen UT

The uniaxial tensile tests UT were carried out on dumbbell specimens of type IV (Fig. 4).

Thickness T = 6 mm, width of narrow section Wc = 6 mm, length of narrow section L = 33 mm, width overall Wo = 19 mm, length overall Lo = 100 mm, gage length G = 25 mm, distance between grips D = 65 mm, Outer radius Ro = 25 mm and radius of fillet R = 14 mm. The experimental input data are summarized in Table 3. The mechanical tests were carried out with a Zwick–Roell-type machine with a capacity of 20KN [10].

All dimensions of the specimens are taken according to ASTM standard D638-03 [11]. The specimens were picked from the welded HDPE pipe (Butt-welding) parallel to the direction of extrusion. And were stretched by two stretching speeds (Ve = 10 and 50 mm/min). For the two stretching speeds proposed during the test, the right strain rate was determined graphically for each of the two cases studied.

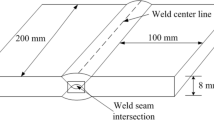

In this work, the weld bead width was measured according to ASTM standard F2620-11, as shown in Fig. 2.

Hardness Shore D Tests

The hardness shore D measurement gives us a first evaluation of the mechanical properties after butt-welding. By this technique, we have drawn thickness hardness profiles of bead-welded perpendicular and parallel to the welding center as shown in Fig. 12

The fusion microstructure was broken into five distinct structures, namely:

-

(1) Skin remnant; (2) spherulitic, slightly elongated; (3) columnar; (4) boundary nucleation; (5) spherulitic.

The hardness shore D tests specimens are prepared by cutting several slabs from the pipe in the longitudinal direction (Fig. 5). The hardness shore D procedure is far simpler than the others. In this part, three cases of measurement are studied (Fig. 6).

-

Testing the hardness shore D perpendicular to the bead weld (case A);

-

Testing the hardness shore D parallel to the bead weld (case B);

-

Testing the hardness shore D at the edge of the exterior diameter (case C).

The hardness shore D tests were carried out according to ASTM standard D2240-00 [12] by a shore D durometer set on a milling machine.

The indenter is moved into the test material under a preliminary distance from 2.5 mm; this distance is set according to the ASTM standard D2240-00 (Fig. 7).

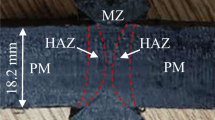

To study the effect of welding conditions on the macro and microstructure of butt-fused PE pipes, the term macro and microstructures are used here to describe the shapes and geometry of the weld zone and the microstructural features within the weld zone.

Experimental Results and Discussion

Tensile Test Results

The results obtained from the tensile tests for different stretching speeds are shown in Figs. 8, 9, 10 and 11. It is observed that the general appearance of stress–strain curves characterized by four main zones: (I) a linear response that translates the elastic behavior to the small deformations; a second part (II) which reflects the appearance of the plastic deformation; a third part (III) characterizing the beginning of the structural hardening stage due to the reorganization of the chains in the direction of stress; and finally, the last part (IV) marked by a hardening before the final rupture. These figures show that the mechanical behavior of these two different stretching speeds takes into account the sensitivity to the strain rate.

For the case of unwelded specimens, it is observed that the base material is ductile at high stress for which the lifetime is sensitive to the stress with a stressing speed Ve = 10 mm/min and with an ultimate tensile strength of 249.899%. At a stretching speed Ve = 50 mm/min, this material has a fragile character for which the lifetime is much less sensitive to stress since the strain at break is 50.82%. At the same stretching speed Ve = 50 mm/min, this welded material has a fragile character for which the lifetime is much less sensitive to stress since the breaking strain is 52.51%. This means that the plastic deformation zone is larger in the case of the unwelded specimens than the welded ones. The ductility of the welded sample, however, was drastically reduced.

These results obtained that the HDPE study presents a significant increase in the flow stress with the rate of deformation depending on the Young’s modulus. Some authors [13, 14] and [15] have shown that this increase is due to the secondary process of the molecules. The HDPE exhibits a fragile behavior at different higher stretching speed.

The stretching speed has a great influence on the mechanical response of HDPE. In particular, the elastic limit increases with the stretching speeds.

At a low stretching speed (Ve = 10 mm/min), and for both cases, specimens made of base material and welded material, the curves presented two parts: linear which can be interpreted as a linear elastic behavior which seems to have a true slope as a function of the deformation rate and the nonlinear which indicates the sensitivity of the deformation velocity.

On the other hand, by increasing the stretching speed of (Ve = 50 mm/min), the curves do not reach the part that characterizes the curing stage before the final rupture.

This leads us to say that welding with the proposed parameters at a stretching speed of Ve = 10 mm/min is efficient.

Hardness Shore D Tests

Microstructure of weld zone and heat-affected zone (HAZ) plays an important role in determining the ultimate quality and mechanical properties of the welding.

This section shows the results of the experimental hardness shore D tests. The hardness shore D measurement studies on butt fusion welds have been carried out by a number of researchers [16] used transmitted polarized light microscopy and identified four zones in high-density polyethylene HDPE welds. The etched surfaces of the weld exhibited five different zones and are illustrated in Fig. 12. Generally, the degree of the flow of the melt was detected in the microtomed section of the weld taken between crossed polarisers. They suggested that the contrast between the weld and the melt affected zone (MAZ) was due to the difference in orientation of the material. The columnar microstructure suggests that atomic shadowing dominates the surface diffusion of the microstructure.

Case A: Testing the Hardness Shore D to the Bead Weld Perpendicular to the Half Thickness Axis of Pipe

Figure 13 shows a schematization of the appearance of hardness profiles following distance from pipe thickness. The results of case A were used to study the fragility or ductility of the weld zone of HDPE material pipeline. In the case A, the results obtained illustrate a uniform distribution of hardness in the bead weld, there is a decrease in hardness occurring at the boundary nucleation zone and slightly elongation zone. The heat-affected zone (HAZ) size, width of the HAZ, is a good indicator of the weld quality. In this case, the hardness increases slightly up to the base material BM. The heat-affected zone (HAZ) is the region in which the structure is affected by the applied heat. It comes from the restoration. This phenomenon is characterized by the recombination and rearrangement of dislocations leading to a slight decrease in their density. The slight increase in hardness shore D in the remnant of skin and columnar or boundary nucleation zones to come from the refinement of the Crystal structure. The spherulitic zone was followed by the columnar zone.

Case B: Testing the Hardness Shore D to the Bead Weld Parallel to the Half Thickness Axis of Pipe

The results of the experimental testing the hardness shore D to the bead weld parallel to the half thickness axis of pipe shown in Fig. 14 explain the hardness distribution of the different zones. At different zones study the hardness value in welding center (36–41 sh) is smaller than the base material BM (58–61 sh) and that means that the heat-affected zone (HAZ) is a fragile zone. Hardness profiles of the various parts explain that the significant degradation of the base material BM to remnant of skin zone and the reduction in the properties depend on the hardening rate of the base material BM. The stability of the hardness at the welding center exactly in the remnant of skin zone can be deemed as a result of the combination of its inherent hardness and its particle size. Presence of thin heat-affected zone (HAZ) implies that there has been excessive melt movement; the bulk of the remnant of skin zone has been pushed out from the joint interface which resulted in a high degree of molecular orientation at the interface, resulting in poor ductility of the welding.

Hardness profiles in part 4 illustrate the right value of the remnant of skin zone.

Case C: Testing the Bead Weld Zone at the Edge of the Exterior Diameter

According to Fig. 15, the zones around the welding in high-density polyethylene with define stress less recrystallization surface, columnar zone and slightly zone deformed surface. The size of the melt affected zone (MAZ) under different heating conditions was established. The presence of voids in the bead interface is attributed to a high heating temperature and prolonged heating time. Transition points A and B submit to a small deformation at heat during butt-welding which makes a little increase in dislocation density.

Conclusion

In this work, we studied the influence of stretching speed (Ve) and strain rate (ε′) on the behavior of the welded tube at the proposed conditions, which is a widely used material in industrial field, namely high-density polyethylene (HDPE).

We carried out an experimental study to test the sensitivity of both unwelded and welded structures by the butt-welding technique. The results of our research agree with the mechanical behavior of many polymers. For the two studied cases shown in Fig. 16, the behavior of the HDPE used is relatively well known at the high stretching speed (Ve = 50 mm/min) and the high strain rate (ε′ = 1.6 s−1). In the case of welded specimens and after testing, the results showed the effect of the fused part (welding bead) on the overall behavior. It is observed that this fused part does not maintain the same mechanical characteristics despite the use of the same welding parameters.

Two comparisons were made between crosshead speed of 10 and 50 mm/min results:

-

Results of the tensile tests of the base material.

-

Results of the tensile tests of the welded material.

The comparison between two crosshead speed results of base material MB subjected to the tensile loads (Ve = 10 and 50 mm/min) is a good correlation between the numerical model (viscoelastic–viscoplastic) and the experimental results obtained. It is thus concluded that the model used is applicable for high-density polyethylene HDPE.

The comparison of the results of the tensile tests was carried out at different stress speeds (welded material). It is summarized that the drawing speed of the welded specimens caused an increase in the elastic limit and reduced the breaking strength. The modulus of elasticity increases with increasing crosshead speed for both welded and unwelded specimens.

After welding, welding bead presents a slight hardening at transition point level, and the strongly deformed zones microstructure A and B at heat was not depended on HDPE initial state; in these zones, the welding conditions such as fusion temperature and the stretching pressure transform the initial structure completely.

References

A.P.D. Costa, E.C. Botelho, M.L. Costa, N.E. Narita, J.R. Tarpani, A review of welding technologies for thermoplastic composites in aerospace applications. Aerosp. Technol. Manag. São José dos Campos 4(3), 255–265 (2012)

K.W. Neale, P. Tugcu, Analysis of necking and neck propagation in polymericmaterials. J. Mech. Phys. Solids 33(4), 323–337 (1985)

H. Potente, P. Tappe, Heated Tool-Butt Welding of Polyethylene-Pipes-Welding Parameters and Testing Technique. Technologie der Kunststoffe, Universftat-GH Pohlweg 47/49 Paderborn, Postfach. Federal Republic of Germany

P.Y. Zhang, Yi, B. Jar, Phenomenological modelling of tensile fracture in PE pipe by considering damage evolution. Mater. Des. 77, 72–82 (2015)

M.F. Butler, A.M. Donald, Deformation of spherulitic polyethylene thin film. J. Mater. Sci. 32, 3675–3685 (1997)

M.F. Butler, A.M. Donald, A.J. Ryan, Time resolved simultaneous smallandwide-angle X-ray scattering during polyethylene deformation-II. Cold drawing of linearpolyethylene. Polymer 1(39), 39–52 (1998)

M. Aboulfaraj, C. G’sell, B. Ulrich, A. Dahoun, In situ observation of plastic deformation of polypropylene spherulites under uniaxial tension and simple shear in the scanning electron microscope. Polymer 36, 731–742 (1995)

A. Djebli, A. Aid, M. Bendouba, A. Talha, N. Benseddiq, M. Benguediab, S. Zengah, Uniaxial fatigue of HDPE-100 pipe. Eng. Technol. Appl. Sci. Res. 4(2), 600–604 (2004)

ASTM F2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings (2011). www.astm.org

Laboratoire Mécanique et Physique des matériaux. (Université Djillali Liabes, Sidi Bel Abbès)

ASTM D638, Standard test method for tensile properties of plastics. Part IIB Plast. (I) 8(1), 1–15 (2003)

ASTM D2240, Standard test method for rubber property-durometer hardness. Part IIB Rubber Nat. Synth. Gen. Test Methods Carbon Black 9(1), 1–8 (2000)

F. Rietsch, B. Bouette, The compression yield behaviour of polycarbonate over a wide range of strain rates and temperatures. Eur. Polym. J. 26, 1071–1075 (1990)

J. Richeton, S. Ahzi, L. Daridon, Y. Rémond, A formulation of the cooperative model for the yield stress of amorphous polymers for a wide range of strain rates and temperatures. Polymer 46, 6035–6043 (2005)

J. Richeton, S. Ahzi, K.S. Vecchio, F.C. Jiang, R.R. Adharapurapu, Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: Characterization and modelling of the compressive yield stress. Int. J. Solids Struct. 43, 2318–2335 (2006)

T. Fawad, N. Nausheen, A.K. Muhammad, A.B. Rasheed, Failure analysis of high density polyethylene butt weld joint. J. Fail. Anal. Prev. (2005). https://doi.org/10.1007/s11668-011-9536-y

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belaziz, A., Mohamed, M. Experimental Study of the Weld Bead Zones of a High-Density Polyethylene Pipe (HDPE). J Fail. Anal. and Preven. 18, 667–676 (2018). https://doi.org/10.1007/s11668-018-0462-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0462-0