Abstract

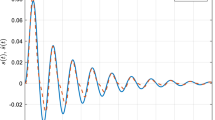

In this study, a method that discriminates between anomalies present or absent in the vibration signal of a flywheel system is developed. First by means of MATLAB and Simulink, a simple flywheel system under different feasible conditions is simulated using equations of motion to capture the dynamic behaviors of the components of the system along their lines of action. The resulting vibration signals obtained from the simulations are combined with varying levels of noise and then subjected to pulse shape analysis (PSA). PSA is a tool that has been mostly used in the field of nuclear engineering, and it is explored and used differently here with the objective of developing a suitable PSA algorithm that can differentiate between vibration signals based on the presence or absence of an anomaly. The algorithm is a time-domain technique with minimal computational time that can be very easily applied. At the end, it is shown that the developed PSA algorithm can identify an anomaly in a vibration signal on the basis of a defined pattern under certain attainable conditions.

Similar content being viewed by others

References

H. Liu, J. Jiang, Flywheel energy storage—an upswing technology for energy sustainability. Energy Build. 39(5), 599–604 (2007)

L. Jiang, W. Zhang, G.J. Ma, C.W. Wu, Shape optimization of energy storage flywheel rotor. Struct. Multidiscipl. Optim. 55(2), 739–750 (2017)

J.-S. Park et al., A structural integrity evaluation for the interference-fit flywheel of reactor coolant pump, in ASME/JSME 2004 Pressure Vessels and Piping Conference, American Society of Mechanical Engineers (2004)

M. Liu et al., Vibration signal analysis of main coolant pump flywheel based on Hilbert–Huang transform. Nucl. Eng. Technol. 47(2), 219–225 (2015)

M.S. Lebold et al., A non-intrusive technique f or on-line shaft crack detection and tracking, in Aerospace Conference, 2005 IEEE, IEEE (2005)

S. Marrone et al., Pulse shape analysis of liquid scintillators for neutron studies. Nucl. Instrum. Methods Phys. Res., Sect. A 490(1), 299–307 (2002)

F. Benrachi et al., Investigation of the performance of CsI (Tl) for charged particle identification by pulse-shape analysis. Nucl. Instrum. Methods Phys. Res., Sect. A 281(1), 137–142 (1989)

G. Gerbier et al., Pulse shape discrimination and dark matter search with NaI (Tl) scintillator. Astropart. Phys. 11(3), 287–302 (1999)

J. Hellmig, H. Klapdor-Kleingrothaus, Identification of single-site events in germanium detectors by digital pulse shape analysis. Nucl. Instrum. Methods Phys. Res., Sect. A 455(3), 638–644 (2000)

G. Pausch, W. Bohne, D. Hilscher, Particle identification in solid-state detectors by means of pulse-shape analysis—results of computer simulations. Nucl. Instrum. Methods Phys. Res., Sect. A 337(2–3), 573–587 (1994)

S. Hussain, H.A. Gabbar, A novel method for real time gear fault detection based on pulse shape analysis. Mech. Syst. Signal Process. 25(4), 1287–1298 (2011)

R.B. Randall, J. Antoni, Rolling element bearing diagnostics—a tutorial. Mech. Syst. Signal Process. 25(2), 485–520 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gabbar, H.A., Mba, C.U., Marchesiello, S. et al. Anomaly Detection in a Reactor Coolant Pump Flywheel System via Pulse Shape Analysis. J Fail. Anal. and Preven. 17, 1174–1181 (2017). https://doi.org/10.1007/s11668-017-0355-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0355-7