Abstract

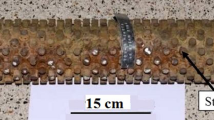

Repeated failures have been experienced in steam coil installed in a water seal vessel. The steam coil was found severely corroded after 9 months of operation especially at the steam inlet. Several samples were collected from different locations for examination and failure investigation. The investigation included visual examination, XRF\CS, and SEM\EDS analysis. It is concluded that the failure mechanism was acid attack caused mainly by sulfuric acid found in the water inside the vessel. It is recommended to eliminate the source of sulfuric acid by controlling the inlet of process gas into the vessel. In addition, measurement of pH and conductivity of the water in the vessel must be conducted regularly. Moreover, under standard operating parameters, material ASTM A-106 Gr. B carbon steel performs well in this environment and material upgrade is not required. However, if it is not feasible to prevent the ingress of sulfuric acid then upgrading the material is necessary.

Similar content being viewed by others

References

ASTM International, Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service. A106/A106M-10 (ASTM International, West Conshohocken, 2010)

Y. Cheng, F.R. Steward, Corrosion of carbon steels in high-temperature water studied by electrochemical techniques. Corr. Sci. 46(10), 2405–2420 (2004)

American Petroleum Institute (API), Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and Alteration, RP 510 (American Petroleum Institute, Washington, DC, 2003)

M. Fontana, Standard Expressions for Corrosion Rate, Corrosion Engineering, 3rd edn. (McGraw-Hill, New York, 1987), pp. 171–174

American Petroleum Institute (API), Damage Mechanisms Affecting Fixed Equipment in the Refining Industry, RP 571 (American Petroleum Institute, Washington, DC, 2003)

M. Davis, P.J.B. Scott, Guide to the Use of Materials in Waters (NACE International, Houston, 2003)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Almaaesab, S., Alrefaie, A. Failure Analysis of Severely Corroded Steam Coil in Water Seal Vessel. J Fail. Anal. and Preven. 15, 782–788 (2015). https://doi.org/10.1007/s11668-015-0036-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-0036-3