Abstract

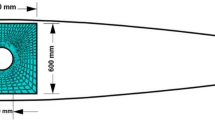

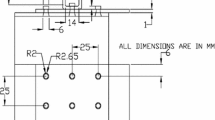

A parametric study on crack initiation was done by having different sizes of cracks at different locations in a rib section of an aircraft using finite element techniques. A semi-elliptical surface flaw in a typical Boeing-747 rib section having circular cut-out and experiencing an in-plane shear loading was considered for the analysis. A laminated composite square plate around a centrally located cut-out was selected in the wing rib for computation purpose. A delamination has been modeled in between the composite layers in the form of a semi-elliptical surface crack using node duplication technique. As there are no theoretical solutions for mixed mode loading problems, the general purpose finite element package ABAQUS was used to obtain the Stress Intensity Factor (SIF) along the crack edge. These stress intensity factor (K C) values were further compared with the fracture toughness of the material to determine the probability of crack initiation. It was observed that the modes of failure change with the dimensions of the crack and also showed a greater tendency towards the crack initiation.

Similar content being viewed by others

Abbreviations

- K :

-

Stress intensity factor

- K Ic :

-

Critical stress intensity factor for mode 1

- K IIc :

-

Critical stress intensity factor for mode 2

- K IIIc :

-

Critical stress intensity factor for mode 3

- c :

-

Semi-major axis

- a :

-

Semi-minor axis

- E 1, E 2, and E 3 :

-

Principal Young’s moduli in fiber direction and other two transverse directions, respectively

- G 12, G 13, and G 23 :

-

Shear moduli associated with planes 1–2, 1–3, and 2–3, respectively

- µ 12, µ 13, and µ 23 :

-

Poisson’s ratio associated with planes 1–2, 1–3, and 2–3, respectively

- σ z :

-

Normal stress component in out of plane direction

- τ 13 and τ 23 :

-

Shear stress components in respective 1–3 and 2–3 planes

- n :

-

Normal vector

- q :

-

Local direction of virtual crack extension

- W :

-

Elastic strain energy

- σ :

-

Applied stress

- I :

-

Identity matrix

- k :

-

Stress intensity factor for auxiliary field

- B :

-

Pre-logarithmic energy factor matrix

- J :

-

J-integral

References

T.L. Anderson, Fracture Mechanics Fundamentals and Applications (CRC Press, Boca Ralton, 1991)

M. Jafari, J. Rezaeepazhand, Stress Concentration in Metallic Plates with Special Shaped Cut-out. Int. J. Mech. Sci. 52, 96–102 (2010)

K.P. Rao, R. Pandey, S. Thakur, K.S. Ramanath, Stress Concentration and Stability Studies in Composite Ribs with flanged cutouts (CAE Group, Infosys Technologies Ltd., Sholinganallur, 2001)

A.D. Kumar, S.B. Singh, Post-buckling strengths of composite laminate with various shaped cutouts under in-plane shear. Compos. Struct. 92, 2966–2978 (2010)

W.T. Chow, S.N. Atluri, Stress intensity factors as the fracture parameters for delamination crack growth in composite laminates. Comput. Mech. 21, 1–10 (1998)

M.H. Dirikolu, A. Aktas, Analytical and finite element comparisons of stress intensity factors of composite materials. Compos. Struct. 50(1), 99–102 (2000)

V. Sivakumar, R.K. Arjun, V. Ishwarya, S. Nithya, S. Sundar, B.N. Thilak, Optimization of Cut-Out on Composite Plate Under In-Plane Shear Loading. J. Fail. Anal. Prev. 12(2), 204 (2012)

ABAQUS, ABAQUS/Standard User’s Manuals, Simulia, Dassault Systems, 2010

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sivakumar, V., Kumar, G.B. & Gautham, A. Crack Initiation Study on Aircraft Composite Rib with Semi-elliptical Surface Flaw. J Fail. Anal. and Preven. 15, 906–914 (2015). https://doi.org/10.1007/s11668-015-0029-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-0029-2