Abstract

The complicated failure mechanisms are always distinct features of composite materials which largely affect the stiffness and strength as well as the structural integrity. Yet, until now there are still no mature methods based on various test approaches for accurately predicting the failure mechanisms and damage evolution behaviors of composite structures by considering the effects of loads, environments, and material defects. This research designs and prepares the [0°16//0°16], [30°16//30°16], and [15°/−15°]3s//[15°/−15°]3s carbon fiber composite specimens with initial interlaminar cracks, and performs the single-leg and over-leg three-point bending mechanical experiments and acoustic emission (AE) tests of composite specimens under 70 °C temperature. The effects of the layup patterns, the loading conditions, and the initial interlaminar crack length on the intralaminar damage and interlaminar delamination behaviors of composite laminates are comparatively studied by analyzing the response process of the AE characteristic parameters including the amplitude, energy, and counting. The AE analysis provides theoretical and technique support for further elucidating the complicated failure mechanisms and their interactions of carbon fiber composite laminates.

Similar content being viewed by others

References

P.W.R. Beaumont, On the problems of cracking and the question of structural integrity of engineering composite materials. Appl. Compos. Mater. 21(1), 5–43 (2014)

P.F. Liu, S.J. Hou, J.K. Chu, X.Y. Hu, C.L. Zhou, Y.L. Liu, J.Y. Zheng, A. Zhao, L. Yan, Finite element analysis of postbuckling and delamination of composite laminates using virtual crack closure technique. Compos. Struct. 93(6), 1549–1560 (2011)

P.F. Liu, J.Y. Zheng, On the through-the-width multiple delamination, and buckling and postbuckling behaviors of symmetric and unsymmetric composite laminates. Appl. Compos. Mater. 20(6), 1147–1160 (2013)

S. Benmedakhene, M. Kenane, M.L. Benzeggagh, Initiation and growth of delamination in glass/epoxy composites subjected to static and dynamic loading by acoustic emission monitoring. Compos. Sci. Technol. 59(2), 201–208 (1999)

X.M. Zhuang, X. Yan, Investigation of damage mechanisms in self-reinforced polyethylene composites by acoustic emission. Compos. Sci. Technol. 66(3–4), 444–449 (2006)

R.T. Bocchieri, R.A. Schapery, M.R. Gorman, Time-dependent microcracking detected in a rubber-toughened carbon–epoxy composite by the modal acoustic emission method. J. Compos. Mater. 37(5), 421–451 (2003)

Y.A. Dzenis, J. Qian, Analysis of microdamage evolution histories in composites. Int. J. Solids Struct. 38(10), 1831–1854 (2001)

M. Johnson, G. Peter, Broad-band transient recording and characterization of acoustic emission events in composite laminates. Compos. Sci. Technol. 60(15), 2803–2818 (2000)

S. Huguet, N. Godin, R. Gaertner, L. Salmon, D. Villard, Use of acoustic emission to identify damage modes in glass fibre reinforced polyester. Compos. Sci. Technol. 62(10), 1433–1444 (2002)

C.R. Ramirez-Jimenez, N. Papadakis, N. Reynolds, T.H. Gan, P. Purnell, M. Pharaoh, Identification of failure modes in glass/polypropylene composites by means of the primary frequency content of the acoustic emission event. Compos. Sci. Technol. 64(12), 1819–1827 (2004)

T. Lutas, V. Kostopoulos, Health monitoring of carbon/carbon, woven reinforced composites. Damage assessment by using advanced signal processing techniques. Part I: Acoustic emission monitoring and damage mechanisms evolution. Compos. Sci. Technol. 69(2), 265–272 (2009)

B.L. Yang, X.M. Zhuang, T.H. Zhang, X. Yan, Damage mode identification for the clustering analysis of AE signals in thermoplastic composites. J. Nondestruct. Eval. 28(3–4), 163–168 (2009)

D.G. Aggelis, N.M. Barkoula, T.E. Matikas, A.S. Paipetis, Acoustic structural health monitoring of composite materials: damage identification and evaluation in cross ply laminates using acoustic emission and ultrasonics. Compos. Sci. Technol. 72(10), 1127–1133 (2012)

M.A. Hamstad, A review: acoustic emission, a tool for composite materials studies. Exp. Mech. 26(1), 7–13 (1986)

M. Fotouhi, F. Pashmforoush, M. Ahmadi, R.A. Oskouei, Monitoring the initiation and growth of delamination in composite materials using acoustic emission under quasi-static three-point bending test. J. Reinf. Plast. Compos. 30(17), 1481–1493 (2011)

A.R. Oskouei, M. Ahmadi, Acoustic Emission characteristics of mode Idelamination in glass/polyester composites. J. Compos. Mater. 44(7), 793–807 (2010)

A.B. de Morais, M.F. de Mourab, A.T. Marquesb, P.T. de Castrob, Mode-I interlaminar fracture of carbon/epoxy cross-ply composites. Compos. Sci. Technol. 62(5), 679–686 (2002)

I. Silversides, A. Maslouhi, G. LaPlante, Acoustic emission monitoring of interlaminar delamination onset in carbon fibre composites. Struct. Health. Monit. 12(2), 126–140 (2013)

J.R. Reeder, J.H. Rews, Mixed-mode bending method for delamination testing. AIAA J. 28(7), 1270–1276 (1990)

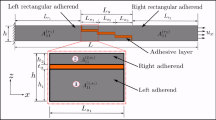

A. Szekrenyes, J. Uj, Over-leg bending test for mixed-mode I/II interlaminar fracture in composite laminates. Int. J. Damage Mech. 16(1), 5–33 (2007)

M. Fotouhi, H. Heidary, M. Ahmadi, F. Pashmforoush, Characterization of composite materials damage under quasi-static three-point bending test using wavelet and fuzzy C-means clustering. J. Compos. Mater. 46(15), 1795–1808 (2012)

J. Bohse, Acoustic emission characteristics of micro-failure processes in polymer blends and composites. Compos. Sci. Technol. 60(8), 1213–1226 (2000)

M. Salavatian, L.V. Smith, The effect of transverse damage on the shear response of fiber reinforced laminates. Compos. Sci. Technol. 95, 44–49 (2014)

K.W. Campbell, P.H. Mott, Damage tolerance in glass reinforced polymer laminates. Compos. Sci. Technol. 95, 21–28 (2014)

F. Ciampa, M. Meo, A new algorithm for acoustic emission localization and flexural group velocity determination in anisotropic structures. Composites A 41(12), 1777–1786 (2010)

R. Hill, R. Brooks, D. Kaloedes, Characterization of transverse failure in composites using acoustic emission. Ultrasonics 36(1), 517–523 (1998)

J.J. Scholey, D.W. Paul, R.W. Michael, I.F. Michael, Quantitative experimental measurements of matrix cracking and delamination using acoustic emission. Compos. Part A 41(5), 612–623 (2010)

R. Gutkin, C.J. Green, S. Vangrattanachai, S.T. Pinho, P. Robinson, P.T. Curtis, On acoustic emission for failure investigation in CFRP: pattern recognition and peak frequency analyses. Mech. Syst. Signal Process. 25(4), 1393–1407 (2011)

T. Czigány, Special manufacturing and characteristics of basalt fiber reinforced hybrid polypropylene composites: mechanical properties and acoustic emission study. Compos. Sci. Technol. 66(16), 3210–3220 (2006)

N. Ativitavas, T. Pothisiri, T.J. Fowler, Identification of fiber-reinforced plastic failure mechanisms from acoustic emission data using neural networks. J. Compos. Mater. 40(3), 193–226 (2005)

N. Godin, S. Hugueta, R. Gaertnera, L. Salmon, Clustering of acoustic emission signals collected during tensile tests on unidirectional glass/polyester composite using supervised and unsupervised classifiers. NDT & E Int. 37(4), 253–264 (2004)

T.P. Philippidis, V.N. Nikolaidis, A.A. Anastassopoulos, Damage characterization of carbon/carbon laminates using neural network techniques on AE signals. NDT & E Int. 31(5), 329–340 (1998)

R. de Oliveira, A.T. Marques, Health monitoring of FRP using acoustic emission and artificial neural networks. Comput. Struct. 86(3–5), 367–373 (2008)

P.F. Liu, J.K. Chu, Y.L. Liu, J.Y. Zheng, A study on the failure mechanisms of carbon fiber/epoxy composite laminates using acoustic emission. Mater. Des. 37, 228–235 (2012)

Chinese National Standard, Fiber-reinforced Plastic Composites—Determination of Flexural Properties (Chinese National Standardization Management Committee, Beijing, 2005) (In Chinese)

Chinese Aerospace Industry Corporation, Chinese Spaceflight Industry Standard Acoustic Emission Inspection Method of Composite Structure (Number QJ2914-97). Beijing: Chinese Aerospace Industry Corporation (1997) (In Chinese)

G.M. Liu, Nondestructive Inspection Technology (National Defence Industry Press, Beijing, 2006) (In Chinese)

X.J.N. Fang, Z.Q. Zhou, B.N. Cox, Q.D. Yang, High-fidelity simulations of multiple fracture processes in a laminated composite in tension. J. Mech. Phys. Solids 59(7), 1355–1373 (2011)

J.H. Williams, S.S. Lee, Acoustic emission monitoring of fiber composite materials and structures. J. Compos. Mater. 12(4), 348–370 (1978)

Acknowledgments

The author Dr. Pengfei Liu would sincerely like to thank the support by the National Natural Science Funding of China (No.51375435), and the National Key Fundamental Research and Development Project (973 Project, No. 2015CB057603), the Natural Science Funding of Zhejiang Province of China (No. LY13E050002) and the Aerospace Support Technique and Innovation Funding.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, P.F., Yang, J., Wang, B. et al. A Study on the Intralaminar Damage and Interlaminar Delamination of Carbon Fiber Composite Laminates Under Three-Point Bending Using Acoustic Emission. J Fail. Anal. and Preven. 15, 101–121 (2015). https://doi.org/10.1007/s11668-014-9901-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-014-9901-8