Abstract

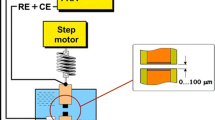

In the oil production, water and acidic gases, i.e., H2S and CO2, are co-produced with the oil. The acidic gases are known to associate with a variety of corrosion damage to the surface facilities leading to costly failures. Also, the acidic gases cause a reduction in the service life of equipment. Corrosion of API L80 tubular carbon steel in sweet media (in the presence of CO2 gas) was investigated using the linear polarization resistance meter. Experiments using API L80 tubular carbon steel material were carried out in a stagnant flow condition with different ratios of produced water to crude oil at relatively high temperatures (60 °C up to 90 °C). The pressure was about 200 psi (13.8 bar) of CO2, and the experiments were carried out using a high pressure vessel namely an autoclave cell. Under those experimental conditions, results indicated that at a temperature of 60 °C, the corrosion rate for carbon steel L80 increased as water-cut ratio increased. Also, the results showed that at higher temperature than 60 °C, the formation of iron carbonate scale on the surface of the steel was observed to increase. Consequently, the corrosion rate of the L80 carbon steel was observed to decrease.

Similar content being viewed by others

References

Kermani, M.B., Harrop, D.: The impact of corrosion on the oil and gas industry. J. SPE Prod. Facil. 8, 186–190 (1996)

Sun, Y., Hong, T., Bosch, C.: Carbon dioxide corrosion in wet gas annular flow at elevated temperatures. Corrosion 59, 733–740 (2003)

Nordsveen, M., Nesic, S., Nyborg, R., Stangeland, A.: A Mechanistic model for carbon dioxide corrosion of mild steel in the presence of protective iron carbonate films—part 1: theory and verification. Corrosion 59, 443–456 (2003)

Kermani, M.B., Morshed, A.: Carbon dioxide corrosion in oil and gas production—a compendium. Corrosion 59, 659–683 (2003)

Schmitt, G., Feinen, S.: Effect of anions and cations on the pit initiation in CO2 corrosion of iron and steel. In: Corrosion/2000, Paper No. 1, NACE 2000, Houston

Efird, K.D., Jasinski, R.J.: The effect of the crude oil on the corrosion of steel in crude oil/brine production. Corrosion 45, 165–171 (1989)

Martins, F.A., Rodrigues, A.P.C., Reznik, L.Y., de Freitas, D.S., Bott, I.: Temperature effect on API grade steels in CO2 environments. In: EUROCORR 2004, Paper No. 274, Nice

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Muhanna, K., Habib, K. Experimental Study on the Effect of the Water-Cut Conditions on the Performance of L80 Carbon Steel. J Fail. Anal. and Preven. 13, 98–101 (2013). https://doi.org/10.1007/s11668-012-9640-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-012-9640-7