Abstract

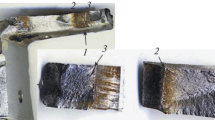

One of the 12 screws meant to fasten the diffuser segment to the flange of a turbine casing in an aeroengine was found broken in-service. Cracks were also observed in some of the remaining screws. The screws made of 35NC6 steel material were plated with cadmium. The chemistry, hardness, and microstructure (heat-treatment condition) of the screws met the drawing requirements. Heavy oxidation was noticed on the surface as well as on the fracture surface of the screws. Fractographic studies showed brittle intergranular features. Scanning electron microscope–energy dispersive x-ray spectroscopy (SEM–EDS) analysis detected cadmium on the entire fracture surface of the screws. Micro-examination and SEM–EDS analysis of the cracked screws showed the presence of cadmium all along the path of crack propagation including the crack tip. From microscopic and fractographic studies, it was concluded that the screws had failed by liquid-metal-induced embrittlement (LMIE). It appeared that the screws had experienced high service temperature that had resulted in melting of the cadmium plating on the screws. The molten cadmium had penetrated (adsorbed) along the grain boundaries of the screw material causing the screws to eventually fail in the brittle (intergranular) manner by the phenomenon of LMIE.

Similar content being viewed by others

References

ASM International: Liquid-metal embrittlement. In: Failure Analysis and Prevention, ASM Handbook, vol. 11, pp. 225–227. ASM International, Materials Park, OH (1995)

ASM International: Failures of locomotive axles. In: Failure Analysis and Prevention, ASM Handbook, vol. 11, pp. 717–718. ASM International, Materials Park, OH (1995)

ASM International: Embrittlement by solid-metal environments. In: Failure Analysis and Prevention, ASM Handbook, vol. 11, 239 pp, ASM International, Materials Park, OH (1995)

Acknowledgments

The authors express their sincere gratitude to Shri S. P. Singh, General Manager (Foundry & Forge Division) for his constant encouragement and support in conducting failure analysis work in the laboratory and for permitting us to publish the case study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nandi, V., Bhat, R.R., Yatisha, I.N. et al. Liquid-Metal-Induced Embrittlement in Turbine Casing Segment Screws of an Aeroengine. J Fail. Anal. and Preven. 12, 348–353 (2012). https://doi.org/10.1007/s11668-012-9579-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-012-9579-8