Abstract

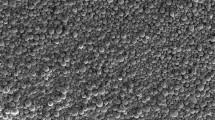

A failed die, used to forge gas valves, was analyzed using macroscopic and microscopic equipment on some specimens. Fatigue cracks on the die were evidently observed on all the surfaces of the die. Many processes were found to be major contributors to have caused the die failure. Oxidation was observed in some areas, especially on plane surfaces and thin sections. Surface layers of tools at the tool-workpiece interface were not only exposed to high mechanical stresses but also to severe temperature cycles, which could have led to loss of strength and hardness. Metallographic analysis revealed that the oxide layers consisted of different diffusion layers which accelerated thermal fatigue mechanisms.

Similar content being viewed by others

References

Chastel, Y., Caillet, N., Bouchard, P.O.: Quantitative analysis of the impact of forging operations on fatigue properties of steel components. J. Mater. Process. Technol. 177, 202–205 (2006)

Gagg, C.R., Lewis, P.R.: Wear as a product failure mechanism—overview and case studies. Eng. Fail. Anal. 14, 1618–1640 (2007)

Gagg, C.R., Lewis, P.R.: In-service fatigue failure of engineered products and structures—case study review. Eng. Fail. Anal. 16, 1775–1793 (2009)

Santos, C.A., Aguilar, M.T.P., Campos, H.B., Pertence, A.E.M., Cetlin, P.R.: Failure analysis of the die in the third hot forging stage of a gear blank. Eng. Fail. Anal. 13, 886–897 (2006)

Kchaou, M., Elleuch, R., Desplanques, Y., Boidin, X., Degallaix, G.: Identification of failure mechanisms of H13 die on relation to the forging process—a case study of brass gas valves. Eng. Fail. Anal. 17, 403–415 (2010)

Njeh, F., Kchaou, M., Elleuch, R., Hallouani, F.: Failure modes of die used for hot forging. In: Premier Congrès Tunisien de Mécanique (COTUME 2008), Hammamet, 17–19 Mar 2008

Felder, E., Montagut, J.L.: Friction and wear during the hot forging of steels. Tribol. Int. 20, 61–68 (1980)

Kchaou, M., Elleuch, R., Desplanques, Y., Boidin, X., Degallaix, G.: Etude du comportement de l’acier X40CrMoV5-1 pré-oxydé en frottement-usure sous faible vitesse de glissement. Ann. Chim. Sci. Mater. 35(1), 41–57 (2010)

Sobis, T., Engel, U., Geiger, M.: A theoretical study on wear simulation in metal forming processes. J. Mater. Process. Technol. 34, 233–240 (1992)

Kanga, J.H., Parkb, I.W., Jaec, J.S., Kang, S.S.: A study on die wear model considering thermal softening (II): application of the suggested wear model. J. Mater. Process. Technol. 94, 183–188 (1999)

Brucelle, O., Bernhart, G.: Methodology for service life increase of hot forging tools. J. Mater. Process. Technol. 87, 237–246 (1999)

Sjöström, J., Bergström, J.: Thermal fatigue testing of chromium martensitic hot-work tool steel after different austenitizing treatments. J. Mater. Process. Technol. 153–154, 1089–1096 (2004)

Spera, D.A.: What is thermal fatigue? Thermal fatigue of materials components. In: ASTM STP 612, pp. 3–9. ASTM, Philadelphia (1976)

Acknowledgments

The authors wish to thank the management and the employees of SOPAL Society for their cooperation and assistance in the preparation of samples for laboratory analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Njeh, F., Kchaou, M., Elleuch, R. et al. Analysis of Degradation and Failure Mechanisms that Develop in Hot Forging Die. J Fail. Anal. and Preven. 12, 273–280 (2012). https://doi.org/10.1007/s11668-012-9556-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-012-9556-2