Abstract

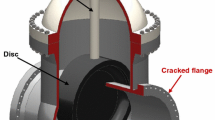

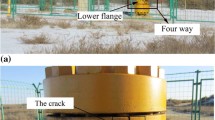

A cracked reducer flange was analyzed for the cause of the failure. The flange was carefully cut to obtain samples for metallographic, X-ray, and scanning electron microscopy (SEM) Examinations. The examinations revealed that the introduction of chloride ions in the operational service led to pitting corrosion in the inner surface of the flange. Chloride ion inclusions were probably the result of chemical contaminations, i.e., cleaning chemicals’ contamination during shutdown of the operation. The introduction of corrosion pits caused unexpected load stress intensification and cracking of the flange. Consequently, stress corrosion cracking emanated from the pits under the influence of chloride attack and operational pressure. Then the cracks propagated in a transgranular manner, in the radial direction of the flange, until the final failure occurred.

Similar content being viewed by others

References

American Society for Metals (ASM): Metals Handbook, Properties and Selection, Iron, Steel, and High Performance Alloys, vol. 1, 10th edn, pp. 843, 856. American Society for Metals, Materials Park, OH (1990)

American Society for Metals (ASM): ASM Standards in Building Codes, vol. 1,A1-B210 M, 13th edn, p. 508. American Society for Metals, Materials Park, OH (1993)

Uhlig, H.: Corrosion and Corrosion Control, 3rd edn, p. 36. John Wiley & Sons Inc., New york (1971)

American Society for Metals (ASM): Case Histories in Failure Analysis, p. 366. American Society for Metals, Materials Park, OH (1979)

Shigley, J.W.: Mechanical Engineering Design, 3rd edn, pp. 28, 60, 169. McGraw-Hill, New York (1977)

Murakami, Y.: Stress Intensity Factors Handbook, vol. 1, p. 307. Pergamon, Oxford (1987)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Habib, K. Failure Analysis of Cracked Reducer Flange. J Fail. Anal. and Preven. 10, 480–485 (2010). https://doi.org/10.1007/s11668-010-9389-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-010-9389-9