Abstract

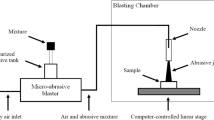

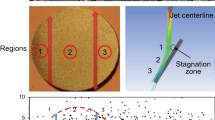

A material failure model (MFM) of progressive damage initiation and propagation for the impingement of solid and liquid particles on the solid surfaces was used to numerically simulate the slurry erosion process. The commercially available 3D Finite Element Analysis (FEA) package ABAQUS/Explicit was used to evaluate this problem. The damage caused on the solid surfaces by the impingement of solid and liquid particles is called the slurry erosion. The proposed model uses the FEA concepts of adaptive meshing, strain-dependent damage initiation criteria, a general contact algorithm, damage propagation, enhanced hourglass section control, and multiple particle impingements to study the slurry erosion process. For the purpose of experimental validation and due to the availability of material properties, surface coatings of an alloy of steel are deposited by the Laser-Based Direct Metal Deposition (LBDMD) process. The slurry erosion tests are performed on these depositions using the ceramic proppant at different impingement angles. The tests are made in a centrifugal force driven erosion testing machine. From these tests, the material removal rate (MRR) values and depth of penetration including the profiles of the craters are computed as a function of the slurry jet impingement angles. The numerically computed results are compared with the experimental results and are shown to be in good agreement.

Similar content being viewed by others

References

Hutchings I.M., Hutchings I.: Tribology: Friction and Wear of Engineering Materials. 2nd edn. Butterworth-Heinemann Press, London (1992)

I. Finnie: The mechanism of erosion of ductile metals. Proceedings of the Third National Congress on Applied Mechanics, New York, 1958, pp. 527–532

Finnie, I.: Erosion of surfaces by solid particles. Wear 3, 87–103 (1960)

Bitter, J.: A study of erosion phenomena, part 1. Wear 6, 5–21 (1963)

Bitter, J.: A study of erosion phenomena, part 2. Wear 8, 161–190 (1963)

Hutchings, I.M.: A model for the erosion of metals by spherical particles at normal incidence. Wear 70, 269–281 (1981)

Hashish, M.: An improved model of erosion by solid particle impact. 7th International Conference on Erosion by Liquid and Solid Impact, Cambridge, pp. 461–480 (1987)

Woytowitz, P.J., Richman, R.H.: Solid mechanics modeling of erosion damage. In: McDowell, D.L. (ed.) Applications of Continuum Damage Mechanics to Fatigue and Fracture, ASTM STP 1315, American Society for Testing and Materials, pp. 186–199 (1997)

Chen, D., Sarumi, M., Al-Hassani, S.T.S.: Computational mean particle erosion model. Wear 214, 64–73 (1998)

Elalem K., Li D.Y.: Dynamical simulation of an abrasive wear process. J. Comput. Aid. Mat. Des. 6, 185–193 (1999)

Shimizu, K., Noguchi, T., Seitoh, H.¸Okada, M., Matsubara, Y.: FEM analysis of erosive wear. Wear 250, 779–784 (2001)

Chen, Q., Li, D.Y.: Computer simulation of solid particle erosion. Wear 254, 203–210 (2003)

Papini, M., Ciampini, D., Krajac, T., Spelt, J.K.: Computer modeling of interference effects in erosion testing: effect of plume shape. Wear 255, 85–97 (2003)

Griffin, D., Daadbin, A., Datta, S.: The development of a three-dimensional finite element model for solid particle erosion on an alumina scale/MA956 substrate. Wear 256, 900–906 (2004)

Eltobgy, M.S., Ng, E., Elbestawi, M.A.: Finite element modeling of erosive wear. Int. J. Mach. Tool. Manu. 45, 1337–1346 (2005)

Kovacevic, R.: System and method for fabrication and repairing part. US Patent 7,020,539, 28 March 2006

Kovacevic, R., Hu, D., Valant, M.: System and method for controlling the size of the molten pool in laser-based additive manufacturing. US Patent 6,995,334, 7 February 2006

ABAQUS Inc., Volume II—Analysis User’s Manual, V.6.5, (2005)

Acknowledgments

The authors would like to acknowledge the financial support from Halliburton Energy Services through joining the NSF Industry University Co-operative Research Center for Laser Aided Manufacturing program. The authors would like to acknowledge Mr. Suresh Krishnan of ABAQUS South for his help with the numerical simulation; Mr. Michael Valant, Dr. Srdja Zekovic, and Dr. Vijay Soundararajan of SMU RCAM/CLAM for their help in performing the experiments and numerical simulation; Dr. Syed Hamid and Dr. Haoyue Zhang of Halliburton Energy Services for technical discussions; and Mr. Roy Beavers of SMU for SEM support. The A11-LVC steel alloy powders and Econoprop 20/40 are supplied by Carpenter Powder Products and Carbo Ceramics, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yarrapareddy, E., Kovacevic, R. Numerical Simulation and Characterization of Slurry Erosion of Laser Cladded Surfaces by Using Failure Analysis Approach. J Fail. Anal. and Preven. 7, 464–474 (2007). https://doi.org/10.1007/s11668-007-9083-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-007-9083-8