Abstract

Results from the sealing of porosity by impregnation show that below a certain wetting angle of the sealant, high penetration depths are achieved. However, only sealants with very low curing shrinkages can prevent the transport of electrolyte through the coating.

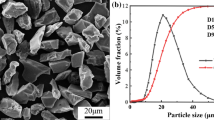

Various sealant types and impregnation methods are discussed, and factors influencing impregnation and sealing ability of sealants are reviewed. Experimental results from the sealing of plasma-sprayed aluminum-oxide coatings are presented.

Similar content being viewed by others

References

K.M. Jasim, R.D. Rawlings, and D.R.F. West, Characterization of Plasma-Sprayed Layers of Fully Yttria-Stabilized Zirconia by Laser Sealing, Surf. Coat. Technol., Vol 53, 1992, p 75–86

A. Petitbon, L. Boquet, and D. Delsart, Laser Surface Sealing and Strengthening of Zirconia Coatings, Surf. Coat. Technol., Vol 49, 1991, p 57–61

K.A. Khor, Hot Isostatic Pressing Modifications of Pore Size Distribution in Plasma Sprayed Coatings, Mater. Manuf. Process., Vol 12 (No. 2), 1997, p 291–307

T. Mäntylä, P. Vuoristo, and P. Kettunen, Chemical Vapor Deposition Densification of Plasma Sprayed Oxide Coatings, Thin Solid Films, Vol 118, 1984, p 437–444

V.A.C. Haanappel, J.B.A. Scharenborg, H.D. van Corbach, T. Fransen, and P.J. Gellings, Can Thermal Barrier Coatings be Sealed by Metal-Organic Chemical Vapor Deposition of Silica and Alumina?, High Temp. Mater. Process., Vol 14 (No. 2), April 1995, p 57–66

Plasma-Spray Coating, Principles and Applications, R.B. Heimann, Ed., VCH Verlagsgesellschaft, Weinheim, 1996, p 164–165

A. Neville and T. Hodgkiess, Corrosion Behavior and Microstructure of Two Thermal Spray Coatings, Surf. Eng., Vol 12 (No. 4), 1996, p 303–312

A.A. Ashary and R.C. Tucker, Jr., Electrochemical and Long-Term Corrosion Studies of Several Alloys in Bare Condition and Plasma Sprayed with Cr2O3, Surf. Coat. Technol., Vol 43/44, 1990, p 567–576

A. Ohmori and C.-J. Li, Quantitative Characterization of the Structure of Plasma-Sprayed Al2O3 Coating by Using Copper Electroplating, Thin Solid Films, Vol 201, 1991, p 241–252

S.L. Wolfson, Corrosion Control of Subsea Piping Systems Using Thermal Sprayed Aluminum Coatings, Mater. Perform., July 1996, p 32–38

E. Lugscheider, P. Jokiel, V. Messerschmidt, and G. Beckschulte, Subsequent Sealing of Thermal Spray Coatings to Increase Corrosion Resistance, Surf. Eng., Vol 10 (No. 1), 1994, p 46–51

B. Wielage, U. Hofmann, S. Steinhäuser, and G. Zimmermann, Improving Wear and Corrosion Resistance of Thermal Sprayed Coatings, Surf. Eng., Vol 14 (No. 2), 1998, p 136–138

P. Chraska, V. Brozek, B.J. Kolman, J. Ilavsky, K. Neufuss, J. Dubsky, and K. Volenik, Porosity Control of Thermal Spray Ceramic Deposits, Thermal Spray—Meeting the Challenges of the 21st Century, C. Coddet, Ed., ASM International, 1998, p 1299–1304

K. Niemi, P. Sorsa, P. Vuoristo, and T. Mäntylä, Thermal Spray Alumina Coatings with Strongly Improved Wear and Corrosion Resistance, Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, 1994, p 533–536

E. Leivo, M. Vippola, P. Sorsa, P. Vuoristo, and T. Mäntylä, Wear and Corrosion Properties of Plasma Sprayed Al2O3 and Cr2O3 Coatings Sealed by Aluminum Phosphates, J. Therm. Spray Technol., Vol 6 (No. 2), 1997, p 205–210

J. Knuuttila, S. Ahmaniemi, and T. Mäntylä, Wet Abrasion and Slurry Erosion Resistance of Thermal Spray Oxide Coatings, Nordtrib ’98: Proc. 8th International. Conf. Tribology, S. Eskildsen, D. Larsen, H. Reitz, E. Bienk, and C. Straede, Ed., Danish Technological Centre, Aarhus, Denmark, 1998, p 873–880

I. Berezin and T. Troczynski, Surface Modification of Zirconia Thermal Barrier Coatings, J. Mater. Sci. Lett., Vol 15, 1996, p 214–218

G. John and T. Troczynski, Surface Modification of Thermal Sprayed Coatings, Thermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, Ed., ASM International, 1996, p 483–488

J. Kathikeyan, C.C. Berndt, A. Ristorucci, and H. Herman, Ceramic Impregnation of Plasma Sprayed Thermal Barrier Coatings, Thermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, Ed., ASM International, 1996, p 477–482

K. Moriya, H. Tomino, Y. Kandaka, T. Hara, and H. Ohmori, Sealing of Plasma-Sprayed Ceramic Coatings by Sol-Gel Process, Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, 1994, p 549–553

H. Ito, R. Nakamura, and M. Shiroyama, Infiltration of Copper into Titanium-Molybdenum Spray Coatings, Surf. Eng., Vol 4 (No. 1), 1988, p 35–38

A. Ohmori, Z. Zhoue, and K. Inoue, Improvement of Plasma-Sprayed Ceramic Coating Properties by Heat-Treatment with Liquid Mn, Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, 1994, p 543–548

A. Ohmori, Z. Zhoue, K. Inoue, K. Murakami, and T. Sasaki, Sealing and Strengthening of Plasma-Sprayed ZrO2 Coating by Liquid Mn Alloy Penetration Treatment, Thermal Spraying—Current Status and Future Trends, A. Ohmori, Ed., High Temperature Society of Japan, 1995, p 549–554

“Determination of Viscosity with Höppler Viscosimeter,” SFS 3758, Finnish Standards Association, 1977; DIN53015; SIS 02 35 13 (in Finnish)

“Methods of Testing Advanced Technical Ceramics—Part 2: Determination of Density and Porosity,” prEN 623-2;1991, CEN European Committee for Standardization

“Standard Practice for Conducting Dry Sand/Rubber Wheel Abrasion Tests,” ASTM G 65–94

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Knuuttila, J., Sorsa, P., Mäntylä, T. et al. Sealing of thermal spray coatings by impregnation. J Therm Spray Tech 8, 249–257 (1999). https://doi.org/10.1007/s11666-999-0002-2

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s11666-999-0002-2