Abstract

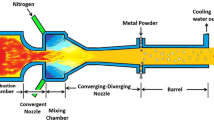

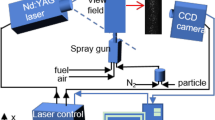

A simple device was constructed for determining a value for the average combustion gas velocity at the exit plane of a high-velocity oxyfuel gun. This device was used to measure the velocities of a standard factory-made barrel nozzle and a specially designed de Laval nozzle as a function of the fuel/oxygen ratio and the total mass flow rate. The Mach number of the de Laval nozzle was 1.42. The maximum combustion gas exit velocities determined for the standard and the de Laval nozzles were 1100 and 1550 m/s, respectively. The maximum velocity depends on the fuel/oxygen ratio but is independent of the total flow rate. The effect of increased combustion gas velocity on coating quality is demonstrated.

Similar content being viewed by others

References

K. Korpiola, H. Jalkanen, and J.P. Hirvonen, Oxygen Partial Pressure Measurements in the Gun Tail Flame, 7995 Advances in Thermal Spray Science and Technology, C.C. Berndt and S. Sampath, Ed., ASM International, 1995, p 181–186

W.D. Swank, J.R. Fincke, D.C. Haggart, and G. Irons, HVOFGas Flow Field Characteristics, Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, 1994, p313–330

C.M. Hackett and G.S. Settles, The Influence of Nozzle Design on HVOF Spray Particle Velocity and Temperature, 1995 Advances in Thermal Spray Science and Technology, C.C. Berndt and S. Sampath, Ed., ASM International, 1995, p 135–146

G.P. Sutton, Rocket Propulsion Elements, 5th Ed., John Wiley & Sons, 1986, p 49–68

J.D. Anderson, Fundamentals of Aerodynamics, McGraw-Hill, 1984, p 42–120

J.D. Anderson, Jr., Modern Compressible Flow, McGraw-Hill, 1990, p 30–130

G.B. Beasom, Jr., T.N. McKechnie, and F.R. Zimmerman, Bell Con- tours, Parallel Flow Nozzle for Reducing Overspray in Thermal Spray Process, 1995 Advances in Thermal Spray Science and Technology, C.C. Berndt and S. Sampath, Ed., ASM International, 1995, p 61–66

J. Grey, P.F. Jacobs, and M.P. Sherman, Calorimetric Probe for the Measurements of Extremely High Temperatures, Rev. Sci: Instrum., Vol 33, 1962, p 738–741

W.D. Swank, J.R. Finceke, and D.C. Haggard, Modular Enthalpy Probe and Gas Analyser for the Thermal Plasma Measurements, Rev. Sci. In- strum., Vol 64 (No. 1), 1993, p 56–62

M.L. Thorpe and H. J. Richter, A Pragmatic Analysis and Comparison of HVOF Process, Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 137–147

HSC Chemistry for Windows, ver. 2.0, Outokumpu Research (Finland), 1994

B.K. Hodge and K. Koenig, Compressible Fluid Dynamics, Prentice Hall, 1995, p 200–295

M. Thorpe and H. Richter, “A Pragmatic Analysis and Comparison of HVOF Processes,” Hobart TAFA Technologies, 1992

Y.M. Timmat, Advanced Chemical Rocket Propulsion, Academic Press, 1987, p 266

J.D. Anderson, Hypersonic and High Temperature Gas Dynamics, McGraw-Hill, 1989, p 690

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Korpiola, K., Hirvonen, J.P., Laas, L. et al. The influence of nozzle design on HVOF exit gas velocity and coating microstructure. J Therm Spray Tech 6, 469–474 (1997). https://doi.org/10.1007/s11666-997-0033-5

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s11666-997-0033-5