Abstract

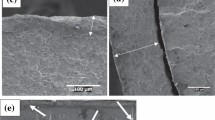

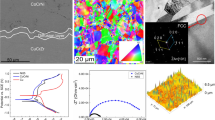

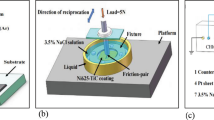

The development of protective coatings on copper alloy surfaces represents a critical research direction to enable the widespread industrial application of copper alloys. To improve the corrosion resistance and wear resistance of the copper alloy plates, a Ni-Cr-Co-based multi-principal element alloy coating was prepared via high-velocity oxygen fuel (HVOF). Then, the microstructure, corrosion resistance, and wear resistance of the Ni-Cr-Co coating and the electroplated NiCo coating were analyzed comparatively. The research results show that the phases of the Ni-Cr-Co coating contained face-centered cubic (FCC) solid solution, CrB and M23C6. The NiCo coating exhibited a single-phase FCC solid solution structure. Compared to the NiCo coating, the corrosion current density of the Ni-Cr-Co coating was reduced by 92.1% in NaF solution. A highly protective passive film was formed on the Ni-Cr-Co coating, and its low ΣCSL grain boundary proportion reached as high as 25.7%. Therefore, the Ni-Cr-Co coatings demonstrated superior corrosion resistance. The scratch wear coefficient of the Ni-Cr-Co coating was only 51.9% of that of the NiCo coating, due to the synergistic strengthening of the matrix and hard second phase. This research offers technical support and a theoretical basis foundation for the development of coatings on copper alloys with excellent corrosion resistance and wear resistance.

Similar content being viewed by others

References

H. Firouzi-Nerbin, F. Nasirpouri, and E. Moslehifard, Pulse Electrodeposition and Corrosion Properties of Nanocrystalline Nickel-Chromium Alloy Coatings on Copper Substrate, J. Alloys Compd., 2020, 822, 153712.

D. Huang, Z. Xu, X. Jia, H. Yu, Y. He, Z. Dong, S. Li, and H. Zhang, Uniform Microstructure and Excellent Corrosion Resistance of HVOF-Sprayed CoCrNi Medium-Entropy Alloy Coating in Fluoride Ion Environment, Met. Mater. Int., 2023, 30, p 61-76.

Z. Xie, C. Zhang, R. Wang, D. Li, Y. Zhang, G. Li, and X. Lu, Microstructure and Wear Resistance of WC/Co-Based Coating on Copper by Plasma Cladding, J. Mater. Res. Technol., 2021, 15, p 821-833.

Y. Liu, T. Xu, Y. Liu, Y. Gao, and C. Di, Wear and Heat Shock Resistance of Ni-WC Coating on Mould Copper Plate Fabricated by Laser, J. Mater. Res. Technol., 2020, 9(4), p 8283-8288.

S. Naghdi, K. Nešović, G. Sánchez-Arriaga, H.Y. Song, S.W. Kim, K.Y. Rhee, and V. Mišković-Stanković, The Effect of Cesium Dopant on APCVD Graphene Coating on Copper, J. Mater. Res. Technol., 2020, 9(5), p 9798-9812.

J. Srnec Novak, A. Lanzutti, D. Benasciutti, F. De Bona, L. Moro, A. De Luca, On the Damage Mechanisms in a Continuous Casting Mold: After-Service Material Characterization and Finite Element Simulation, Eng. Failure Anal., 2018, 94, p 480-492.

S. Hong, J. Qin, J. Lin, Y. Wu, J. Li, and Y. Zheng, Influences of Sand Concentration and Flow Velocity on Hydro-Abrasive Erosion Behaviors of HVOF Sprayed Cr3C2–NiCr and WC–Cr3C2–Ni Coatings, J. Mater. Res. Technol., 2022, 21, p 1507-1518.

V.V. Satyavathi Yedida and H. Vasudev, A Review on the Development of Thermal Barrier Coatings by Using Thermal Spray Techniques, Mater. Today: Proc., 2022, 50, p 1458-1464.

K.A. Habib, D.L. Cano, J.A.H. Alvaro, J. Serrano-Mira, R. Llopis, D.L. Moreno, and S.S. Mohammed, Effects of Thermal Spraying Technique on the Remelting Behavior of NiCrBSi Coatings, Surf. Coat. Technol., 2022, 444, 128669.

Y. Wang, E. Hao, Y. An, J. Chen, and H. Zhou, Effects of Microstructure and Mechanical Properties on Cavitation Erosion Resistance of NiCrWMoCuCBFe Coatings, Appl. Surf. Sci., 2021, 547, 149125.

A.R. Govande, A. Chandak, B.R. Sunil, and R. Dumpala, Carbide-Based Thermal Spray Coatings: A Review on Performance Characteristics and Post-Treatment, Int. J. Refract. Met. Hard Mater., 2022, 103, 105772.

K.A. Habib, D.L. Cano, J. Serrano-Mira, E.R. Encinas, R.S. Dosta, Impact of Microstructure on Remelting Parameters and Mechanical Behavior of Thermally Sprayed NiCrBSi Coating, J. Therm. Spray Technol., 2023, p

S. Zouari, H. Ghorbel, Y. Danlos, H. Liao, and R. Elleuch, Comparative Study of HVOF-Sprayed NiCrBSi Alloy and 316L Stainless Steel Coatings on a Brass Substrate, J. Therm. Spray Technol., 2019, 28(6), p 1284-1294.

M. Aliabadi, F. Khodabakhshi, R. Soltani, and A.P. Gerlich, Modification of Flame-Sprayed NiCrBSi Alloy Wear-Resistant Coating by Friction Stir Processing and Furnace Re-Melting Treatments, Surf. Coat. Technol., 2023, 455, 129236.

S. Lebaili, M. Durand-Charre, and S. Hamar-Thibault, The Metallurgical Structure of As-Solidified Ni-Cr-B-Si-C Hardfacing Alloys, J. Mater. Sci., 1988, 23(10), p 3603-3611.

H.-J. Kim, S.-Y. Hwang, C.-H. Lee, and P. Juvanon, Assessment of Wear Performance of Flame Sprayed and Fused Ni-Based Coatings, Surf. Coat. Technol., 2003, 172(2), p 262-269.

X. Yang, R. Zeng, X. Fu, X. Wang, J. Zhou, and L. Yu, Influence of the Cu Content on the Electrochemical Corrosion Performances of Ni60 Coating, Corros. Sci., 2022, 205, 110408.

C. Pan, M. Gong, S. Feng, X. Chen, X. Zhao, and P. He, Corrosion and Thermal Fatigue Behaviors of Induction-Clad Ni-Coated TiC Particle-Reinforced Ni60 Coating in Molten Aluminum Alloy, Surf. Coat. Technol., 2021, 419, 127278.

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448-511.

F.G. Coury, G. Zepon, and C. Bolfarini, Multi-principal Element Alloys from the CrCoNi Family: Outlook and Perspectives, J. Mater. Res. Technol., 2021, 15, p 3461-3480.

G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler, and E.P. George, Reasons for the Superior Mechanical Properties of Medium-Entropy CrCoNi Compared to High-Entropy CrMnFeCoNi, Acta Mater., 2017, 128, p 292-303.

Q. Pan, L. Zhang, R. Feng, Q. Lu, K. An, A.C. Chuang, J.D. Poplawsky, P.K. Liaw, and L. Lu, Gradient Cell–Structured High-Entropy Alloy with Exceptional Strength and Ductility, Science, 2021, 374(6570), p 984-989.

B. Gludovatz, A. Hohenwarter, K.V.S. Thurston, H. Bei, Z. Wu, E.P. George, and R.O. Ritchie, Exceptional Damage-Tolerance of a Medium-Entropy Alloy CrCoNi at Cryogenic Temperatures, Nat. Commun., 2016, 7(1), p 10602.

A. Meghwal, A. Anupam, B.S. Murty, C.C. Berndt, R.S. Kottada, and A.S.M. Ang, Thermal Spray High-Entropy Alloy Coatings: A Review, J. Therm. Spray Technol., 2020, 29(5), p 857-893.

G. Oppong Boakye, E.O. Straume, B.G. Gunnarsson, D. Kovalov, and S.N. Karlsdottir, Corrosion Behaviour of HVOF Developed Mo-Based High Entropy Alloy Coating and Selected Hard Coatings for High Temperature Geothermal Applications, Mater. Des., 2023, 235, p 112431.

V. Ashokan, V. Gaurav, S.P. Kumaresh Babu, M. Murali, and S. Manivannan, Microstructure Evolution and Erosion Behaviour of Thermally Sprayed AlCoCrNiMo01 High Entropy Alloy Coating, Ceram. Int., 2023, 49(19), p 32331-32336.

A. Meghwal, S. Singh, S. Sridar, W. Xiong, C. Hall, P. Munroe, C.C. Berndt, and A.S.M. Ang, Development of Composite High Entropy-Medium Entropy Alloy Coating, Scripta Mater., 2023, 222, 115044.

G.Y. Koga, A.R.C. Nascimento, F.B. Ettouil, L.C.M. Rodrigues, G. Zepon, C. Bolfarini, C.S. Kiminami, W.J. Botta, R. Schulz, A. Costa e Silva, C. Moreau, and F.G. Coury, Thermally Sprayed Multi-Principal Element Cr40Co40Ni20 Coatings – Oxidation Upon Coatings’ Build-Up and Electrochemical Corrosion, Surf. Coat. Technol., 2023, 454, p 129154.

Z.-Z. Yan, Q.-H. Zhang, H.-R. Cai, X.-R. Li, L.-K. Wu, Z.-Z. Luo, and F.-H. Cao, Study on the Galvanic Corrosion of Titanium and Stainless Steel Couple with the Synergistic Effect of Proton and Fluoride Ion, Corros. Sci., 2022, 206, 110541.

J. Xuan, Y. Xin, L. Xu, M. Guo, L. Huang, Y. Zhang, Y. Zhao, Y. Liu, L. Li, L. Xue, and L. Li, Effects of Fluoride Ions on Corrosion Performance and Surface Properties of SS304 in Simulated PEMFC Cathodic Environments, Renewable Energy, 2023, 212, p 769-778.

S. Gu, L. Yu, G. Wen, P. Tang, Z. Wang, and Z. Gao, Qualitative, Quantitative and Mechanism Research of Volatiles in the Most Commonly Used CaO–SiO2–CaF2–Na2Ο Slag During Casting Process, Trans. Indian Inst. Met., 2021, 74(4), p 775-782.

Z. Zhao, J. Zhao, Z. Tan, B. Qu, and Y. Cui, The Volatilization Behaviour of Typical Fluorine-Containing Slag in Steelmaking, R. Soc. Open Sci., 2020, 7, 200704.

L.J. Zhang, Z.K. Jiang, M.D. Zhang, J.T. Fan, D.J. Liu, P.F. Yu, G. Li, and R.P. Liu, Effect of Solid Carburization on the Surface Microstructure and Mechanical Properties of the Equiatomic CoCrFeNi High-Entropy Alloy, J. Alloys Compd., 2018, 769, p 27-36.

W. Yixuan, L. Qiang, J. Jin, W. Xianshun, and S. Jun, Investigating the Wear Behavior of Fe-Based Amorphous Coatings under Nanoscratch Tests, Metals - Open Access Metallurgy Journal, 2017, 7(4), p 118.

N. Rajasekaran and S. Mohan, A Comparative Study of Cu-Co Alloys versus Cu/Co Multilayered Coatings Obtained by Electrodeposition Techniques, J. Electrochem. Soc., 2012, 159(10), p D577.

T.A. Zimogliadova, A.A. Bataev, D.V. Lazurenko, I.A. Bataev, V.A. Bataev, M.G. Golkovskii, H. Saage, T.S. Ogneva, and A.A. Ruktuev, Structural Characterization of Layers Fabricated by Non-Vacuum Electron Beam Cladding of Ni-Cr-Si-B Self-Fluxing Alloy with Additions of Niobium and Boron, Mater. Today Commun., 2022, 33, 104363.

L. Soldi, A. Laplace, M. Roskosz, and S. Gossé, Phase Diagram and Thermodynamic Model for the Cu-Si and the Cu-Fe-Si Systems, J. Alloys Compd., 2019, 803, p 61-70.

W. Zhang, Y. Du, L. Zhang, H. Xu, S. Liu, and L. Chen, Atomic Mobility, Diffusivity and Diffusion Growth Simulation for fcc Cu–Mn–Ni Alloys, Calphad, 2011, 35(3), p 367-375.

D.J. Chakrabarti and D.E. Laughlin, The Cr-Cu (Chromium-Copper) System, Bulletin of Alloy Phase Diagrams, 1984, 5(1), p 59-68.

M. Palumbo, S. Curiotto, and L. Battezzati, Thermodynamic Analysis of the Stable and Metastable Co–Cu and Co–Cu–Fe Phase Diagrams, Calphad, 2006, 30(2), p 171-178.

J. Du, Y. Li, F. Li, H. Lu, X. Ran, X. Zhang, and X. Qi, Numerical and Experimental Analysis of Temperature Field and Mechanical Analysis for the Multi-layer Cr3C2-NiCr Coating Deposited by HVOF, J. Alloys Compd., 2021, 889, 161656.

P. Yu, N. Fan, Y. Zhang, Z. Wang, W. Li, R. Lupoi, and S. Yin, Microstructure Evolution and Composition Redistribution of FeCoNiCrMn High Entropy Alloy Under Extreme Plastic Deformation, Mater. Res. Lett., 2022, 10(3), p 124-132.

T. Watanabe, An Approach to Grain Boundary Design of Strong and Ductile Polycrystals, Res. Mech., 1984, 11, p 47.

V. Randle, Mechanism of Twinning-Induced Grain Boundary Engineering in Low Stacking-Fault Energy Materials, Acta Mater., 1999, 47(15), p 4187-4196.

M. Kumar, A.J. Schwartz, and W.E. King, Microstructural Evolution During Grain Boundary Engineering of Low to Medium Stacking Fault Energy FCC Materials, Acta Mater., 2002, 50(10), p 2599-2612.

X. Zhang, R. Dong, Q. Guo, H. Hou, and Y. Zhao, Predicting the Stacking Fault Energy in FCC High-Entropy Alloys Based on Data-Driven Machine Learning, J. Mater. Res. Technol., 2023, 26, p 4813-4824.

L. Xu, L. Casillas-Trujillo, Y. Gao, and H. Xu, Compositional Effects on Stacking Fault Energies in Ni-Based Alloys Using First-Principles and Atomistic Simulations, Comput. Mater. Sci., 2021, 197, 110618.

D. Huang, Y. Zhuang, and C. Wang, Advanced Mechanical Properties Obtained via Accurately Tailoring Stacking Fault Energy in Co-Rich and Ni-Depleted CoxCr33Ni67-x Medium-Entropy Alloys, Scripta Mater., 2022, 207, 114269.

W. Yang, P. Qu, J. Sun, Q. Yue, H. Su, J. Zhang, and L. Liu, Effect of Alloying Elements on Stacking Fault Energies of γ and γ′ Phases in Ni-Based Superalloy Calculated by First Principles, Vacuum, 2020, 181, 109682.

H. Jafari, S. Emami, and Y. Mahmoudi, Numerical Investigation of Dual-Stage High Velocity Oxy-Fuel (HVOF) Thermal Spray Process: A Study on Nozzle Geometrical Parameters, Appl. Therm. Eng., 2017, 111, p 745-758.

P. Bansal, P.H. Shipway, and S.B. Leen, Residual Stresses in High-Velocity Oxy-Fuel Thermally Sprayed Coatings – Modelling the Effect of Particle Velocity and Temperature During the Spraying Process, Acta Mater., 2007, 55(15), p 5089-5101.

H. Feng, H.-B. Li, J. Dai, Y. Han, J.-D. Qu, Z.-H. Jiang, Y. Zhao, and T. Zhang, Why CoCrFeMnNi HEA Could not Passivate in Chloride Solution? – A Novel Strategy to Significantly Improve Corrosion Resistance of CoCrFeMnNi HEA by N-Alloying, Corros. Sci., 2022, 204, 110396.

N. Kumar, M. Fusco, M. Komarasamy, R.S. Mishra, M. Bourham, and K.L. Murty, Understanding Effect of 3.5 wt.% NaCl on the Corrosion of Al0.1CoCrFeNi High-Entropy Alloy, J. Nucl. Mater., 2017, 495, p 154-163.

C.A. Della Rovere, J.H. Alano, R. Silva, P.A.P. Nascente, J. Otubo, and S.E. Kuri, Characterization of Passive Films on Shape Memory Stainless Steels, Corros. Sci., 2012, 57, p 154-161.

A. Wetzel, M. von der Au, P.M. Dietrich, J. Radnik, O. Ozcan, and J. Witt, The Comparison of the Corrosion Behavior of the CrCoNi Medium Entropy Alloy and CrMnFeCoNi High Entropy Alloy, Appl. Surf. Sci., 2022, 601, 154171.

Z. Chai and C. Jiang, Corrosion Behavior and Product Film Formation of NiCoCu Nanocrystalline Coatings in Neutral Salt Environments, Electrochim. Acta, 2019, 298, p 616-629.

L. Freire, M.J. Carmezim, M.G.S. Ferreira, and M.F. Montemor, The Electrochemical Behaviour of Stainless Steel AISI 304 in Alkaline Solutions with Different pH in the Presence of Chlorides, Electrochim. Acta, 2011, 56(14), p 5280-5289.

S. Mosayebi, M. Rezaei, and Z. Mahidashti, Comparing Corrosion Behavior of Ni and Ni-Mo Electroplated Coatings in Chloride Mediums, Colloids Surf. A, 2020, 594, p 124654.

Y. Fu, F. Zhou, Q. Wang, M. Zhang, and Z. Zhou, Electrochemical and Tribocorrosion Performances of CrMoSiCN Coating on Ti-6Al-4V Titanium Alloy in Artificial Seawater, Corros. Sci., 2020, 165, 108385.

H. Luo, Z. Li, A.M. Mingers, and D. Raabe, Corrosion Behavior of an Equiatomic CoCrFeMnNi High-Entropy Alloy Compared with 304 Stainless Steel in Sulfuric Acid Solution, Corros. Sci., 2018, 134, p 131-139.

M.C. Biesinger, B.P. Payne, A.P. Grosvenor, L.W.M. Lau, A.R. Gerson, and R.S.C. Smart, Resolving Surface Chemical States in XPS Analysis of First Row Transition Metals, Oxides and Hydroxides: Cr, Mn, Fe, Co and Ni, Appl. Surf. Sci., 2011, 257(7), p 2717-2730.

C. Liu and J. Wu, Influence of pH on the Passivation Behavior of 254SMO Stainless Steel in 3.5% NaCl Solution, Corros. Sci., 2007, 49(5), p 2198-2209.

Y. Fu, J. Li, H. Luo, C. Du, and X. Li, Recent Advances on Environmental Corrosion Behavior and Mechanism of High-Entropy Alloys, J. Mater. Sci. Technol., 2021, 80, p 217-233.

H. Luo, S. Zou, Y.-H. Chen, Z. Li, C. Du, and X. Li, Influence of Carbon on the Corrosion Behaviour of Interstitial Equiatomic CoCrFeMnNi High-Entropy Alloys in a Chlorinated Concrete Solution, Corros. Sci., 2020, 163, 108287.

L. Wang, D. Mercier, S. Zanna, A. Seyeux, M. Laurent-Brocq, L. Perrière, I. Guillot, and P. Marcus, Study of the Surface Oxides and Corrosion Behaviour of an Equiatomic CoCrFeMnNi High Entropy Alloy by XPS and ToF-SIMS, Corros. Sci., 2020, 167, 108507.

X. Shang, Z. Wang, F. He, J. Wang, and J.J.S. Li, The Intrinsic Mechanism of Corrosion Resistance for FCC High Entropy Alloys, Sci. China: Technol. Sci., 2018, 61(2), p 189-196.

J. Gao, J. Tan, X. Wu, and S. Xia, Effect of Grain Boundary Engineering on Corrosion Fatigue Behavior of 316LN Stainless Steel in Borated and Lithiated High-Temperature Water, Corros. Sci., 2019, 152, p 190-201.

D.X. Han, G. Wang, J.L. Ren, L.P. Yu, J. Yi, I. Hussain, S.X. Song, H. Xu, K.C. Chan, and P.K. Liaw, Stick-Slip Dynamics in a Ni62Nb38 Metallic Glass Film During Nanoscratching, Acta Mater., 2017, 136, p 49-60.

J.H. Chang, S.K. Tzeng, J.M. Chou, R.I. Hsieh, and J.L. Lee, Effect of Dry Sliding Wear Conditions on a Vacuum Induction Melted Ni Alloy, Wear, 2011, 270(3), p 294-301.

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 51971001) and the Key Research and Development Project of Anhui Province (No. 2022a05020017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, D., Xu, Z., He, Y. et al. Corrosion and Wear Resistance of HVOF-Sprayed Ni-Cr-Co Multi-principal Element Alloy Coating on Copper Plate. J Therm Spray Tech (2024). https://doi.org/10.1007/s11666-024-01788-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11666-024-01788-2