Abstract

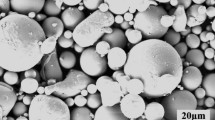

In the current investigation, X70 pipeline steel plate was welded using submerged-arc welding. Thereafter, a (Fe0.5Ni0.2)61Cr9Co6Si1.5B17.5Nb5 amorphous alloy coating with a thickness of 400 ± 30 μm was successfully deposited on the surface of welded X70 pipeline steel by high velocity oxy-fuel (HVOF). The corrosion resistance of the substrate and coating in acidic environments was discussed, and the corrosion mechanisms were analyzed. The results show that the coating is completely amorphous with a dense microstructure, showing a typical thermal spray laminar flow-like structure. The corrosion potential (Ecorr) and self-corrosion current density (Icorr) are − 396 mV and 2.061 × 10−6 A/cm2, respectively. The Ecorr of all coatings is better than that of substrate. The coating A, where the BM zone is located, has the largest capacitance resistance arc radius and the smallest Icorr (1.427 × 10−7 A/cm2), which provides the best corrosion resistance. The maximum Icorr of the coating (Icorr = 2.320 × 10−7 A/cm2) is one order of magnitude lower than the minimum Icorr of the substrate (Icorr = 2.061 × 10−6 A/cm2), which indicates that the coating has better corrosion resistance than the substrate. The corrosion mechanism of the coating in H2SO4 solution is active dissolution of metal elements in the coating (initial stage) and passivation film protection coating (later stage). This work provides a very valuable idea to solve the problem of corrosion failure of X70 pipeline steel.

Similar content being viewed by others

Data Availability

Data used to support the findings of this work are available from the respective authors upon request.

References

A. Golchinvafa, S.H.M. Anijdan, M. Sabzi, and M. Sadeghi, The Effect of Natural Inhibitor Concentration of Fumaria Officinalis and Temperature on Corrosion Protection Mechanism In API X80 Pipeline Steel in 1 M H2SO4 Solution, Int. J. Press. Vessel. Pip., 2020, 188, p 104241.

X.M. Wang, W. Zhao, J.B. Wang, G.C. Xiao, H. Zhang, and N. Guo, Galvanic Corrosion of X80 Pipeline Steel Double-Sided Submerged Arc Welded Joints In Simulated Near-Neutral Soil Solution, Mater. Werks., 2022, 53(3), p 328-343.

S. Zhao, L. He, X. Fan, C. Liu, J. Long, L. Wang, H. Chang, J. Wang, and W. Zhang, Microstructure and Chloride Corrosion Property of Nanocrystalline AlTiCrNiTa High Entropy Alloy Coating on X80 Pipeline Steel, Surf. Coat. Technol., 2019, 375(15), p 215-220.

Q. Fu, J. Xu, B. Wei, Q. Qin, L. Gao, Y. Bai, C. Yu, and C. Sun, The Effect of Nitrate Reducing Bacteria on the Corrosion Behavior of X80 Pipeline Steel in the Soil Extract Solution of Shenyang, Int. J. Press. Vessel. Pip., 2021, 190, p 104313.

Z. Wang, H.F. Lu, J. Cai, L.J. Wu, K.Y. Luo, and J.Z. Lu, Improvement Mechanism in Stress Corrosion Resistance of the X70 Pipeline Steel in Hydrogen Sulfide Solution by Massive Laser Shock Peening Treatment, Corros. Sci., 2022, 201, p 110293.

I.M. Gadala and A. Alfantazi, Electrochemical Behavior of API-X100 Pipeline Steel in NS4, Near-Neutral, and Mildly Alkaline pH Simulated Soil Solutions, Corros. Sci., 2014, 82, p 45-57.

L. Song, Z. Liu, X. Li, X. Guo, Y. Zhang, and W. Wu, Influence of Microstructure on Stress Corrosion Cracking of X100 Pipeline Steel In Carbonate/Bicarbonate Solution, J. Mater. Res. Technol., 2022, 17, p 150-165.

Y. Wang, G. Cheng, W. Wu, Q. Qiao, Y. Li, and X. Li, Effect of pH and Chloride on the Micro-Mechanism of Pitting Corrosion for High Strength Pipeline Steel In Aerated NaCl Solutions, Appl. Surf. Sci., 2015, 349, p 746-756.

Z. Zhu, P.J. Teevens, H. Xue, and Y.F. Cheng, Numerical Simulation and Experimental Verification of Pitting Corrosion Propagation in Sweet Pipeline Service, J. Pip. Sci. Eng., 2021, 2(1), p 78-86.

S. Qian and Y.F. Cheng, Corrosion of Steel in a CO2-Containing Solution Droplet Generated in Wet Gas Pipelines Studied by Scanning Kelvin Probe, J. Pip. Sci. Eng., 2021, 2(1), p 71-77.

K. Gong, M. Wu, and G. Liu, Stress Corrosion Cracking Behavior of Rusted X100 Steel Under the Combined Action of Cl– and HSO3– in a Wet-Dry Cycle Environment, Corros. Sci., 2020, 165, p 108382.

P.Y. Wang, Z.G. Lv, S.Q. Zheng, Y.M. Qi, J. Wang, and Y.J. Zheng, Tensile and Impact Properties of X70 Pipeline Steel Exposed to Wet H2S Environments, Int. J. of Hydrog. Energy, 2015, 40(35), p 11514-11521.

S. Zhao, L.X. He, X.X. Fan, C.H. Liu, J.P. Long, L. Wang, H. Chang, J. Wang, and W. Zhang, Microstructure and Chloride Corrosion Property of Nanocrystalline AlTiCrNiTa High Entropy Alloy Coating on X80 Pipeline Steel, Surf. Coat. Technol., 2019, 375, p 215-220.

D. Toboła, Influence of Sequential Surface Treatment Processes on Tribological Performance of Vanadis 6 Cold Work Tool Steel, Wear, 2022, 488-489, p 204106.

Q. Luo, Y.J. Sun, J. Jiao, Y.X. Wu, S.J. Qu, and J. Shen, Formation and Tribological Behavior of AC-HVAF-Sprayed Nonferromagnetic Fe-Based Amorphous Coatings, Surf. Coat. Technol., 2018, 334, p 253-260.

Y.C. Li, C. Zhang, W. Xing, S.F. Guo, and L. Liu, Design of Fe-Based Bulk Metallic Glasses with Improved Wear Resistance, ACS Appl. Mater. Interfaces, 2018, 10(49), p 43144-43155.

H.B. Wang, C.Y. Li, S.P. Wang, J.L. Li, W.B. Pu, and S.Z. Kou, A Novel Fe-Based Amorphous Powder and Coating with Excellent Wear and Corrosion Resistance, J. Therm. Spray Tech., 2023, 32(4), p 1066-1077.

S. Kumar, M. Kumar, and A. Handa, Combating hot corrosion of boiler tubes-A study, Eng. Fail. Anal., 2018, 94, p 379-395.

H.M. Zhai, H.Y. Yuan, W.S. Li, X.J. Zhang, X.S. Li, and A.H. Cai, Corrosion Resistance Mechanisms of Detonation Sprayed Fe-Based Amorphous Coating on AZ31B Magnesium Alloy, J. Non-Cryst. Solids, 2022, 576, p 121276.

B.S. Xu and S.N. Ma, Development of High Quality and Efficient Surface Technology: Arc Spraying Technology, Mater. Prot., 1993, 26(12), p 683.

J. Kim, K. Kang, S. Yoon, S. Kumar, H. Na, and C. Lee, Oxi-dation and Crystallization Mechanisms in Plasma-Sprayed Cu-Based Bulk Metallic Glass Coatings, Acta Mater., 2010, 58(3), p 952-962.

A.S. Praveen, J. Sarangan, S. Suresh, and B.H. Channabasappa, Optimization and Erosion Wear Response of NiCrSiB/WC-Co HVOF Coating Using Taguchi Method, Ceram. Int., 2016, 42(1), p 1094-1104.

S. Kumar, M. Kumar, and N. Jindal, Overview of cold Spray Coatings Applications and Comparisons: A Critical Review, World J. Eng., 2020, 17(1), p 27-51.

J. Farmer, J. Choi, C. Saw, J. Haslam, D. Day, P. Hailey, T. Lian, R. Rebak, J. Perepezko, J. Payer, D. Branagan, B. Beardsley, A. D’amato, and L. Aprigliano, Iron-Based Amorphous Metals: High-Performance Corrosion-Resistant Material Development, Metall. Mater. Trans. A, 2009, 40(06), p 1289-1305.

B. Bhushan, A. Banerjee, S.N. Patel, D. Banik, K. Godbole, K. Vishwanath, S. Mandal, and K. Mondal, Electrochemical Response and Passivation Affinity of Fe-Based Amorphous HVOF Coatings Prepared from Pig Iron on Mild Steel, Surf. Coat. Technol., 2023, 452, p 129082.

L. Qiao, Y. Wu, S. Hong, Y. Qin, W. Shi, and G. Li, Corrosion Behavior of HVOF-Sprayed Fe-Based Alloy Coating in Various Solutions, J. Mater. Eng. Perform., 2017, 26, p 3813-3820.

J. Wu, S.D. Zhang, W.H. Sun, Y. Gao, and J.Q. Wang, Enhanced Corrosion Resistance in Fe-Based Amorphous Coatings Through Eliminating Cr-Depleted Zones, Corros. Sci., 2018, 136, p 161-173.

Y.C. Li, W.W. Zhang, Y. Wang, X.Y. Zhang, and L.L. Sun, Effect of Spray Powder Particle Size on the Bionic Hydrophobic Structures and Corrosion Performance of Fe-Based Amorphous Metallic Coatings, Surf. Coat. Technol., 2022, 437, p 128377.

J. Jiao, Q. Luo, X. Wei, Y. Wang, and J. Shen, Influence of Sealing Treatment on the Corrosion Resistance of Fe-Based Amorphous Coatings in HCl Solution, J. Alloys Compd., 2017, 714, p 356-362.

S.D. Zhang, W.L. Zhang, S.G. Wang, X.J. Gu, and J.Q. Wang, Characterisation of Three-Dimensional Porosity in an Fe-Based Amorphous Coating and its Correlation with Corrosion Behaviour, Corros. Sci., 2015, 93, p 211-221.

Y. Wang, Z.Z. Xing, Q. Luo, A. Rahman, J. Jiao, S.J. Qu, Y.G. Zheng, and J. Shen, Corrosion and Erosion-Corrosion Behaviour of Activated Combustion High-Velocity Air Fuel Sprayed Fe-Based Amorphous Coatings in Chloride-Containing Solutions, Corros. Sci., 2015, 98, p 339-353.

H.J. Lunk, Discovery, Properties and Applications of Chromium and its Compounds, Chem. Texts, 2015, 1, p 6.

R.K. Williams, R. Graves, and D. Mcelroy, Thermal conductivity of Cr2O3 in the vicinity of the Neel transition, J. Am. Ceram. Soc., 1984, 67, p 151-152.

T. Lin, H.H. Sheu, C.Y. Lee, and H.B. Lee, The Study of Mechanical Properties and Corrosion Behavior of the Fe-Based Amorphous Alloy Coatings Using High Velocity Oxygen Fuel Spraying, J. Alloys Compd., 2021, 867, p 159132.

A. Kumar, S.K. Nayak, P. Bijalwan, M. Dutta, A. Banerjee, and T. Laha, Optimization of Mechanical and Corrosion Properties of Plasma Sprayed Low-Chromium Containing Fe-Based Amorphous/Nanocrystalline Composite Coating, Surf. Coat. Technol., 2019, 370, p 255-268.

R.Q. Guo, C. Zhang, Q. Chen, Y. Yang, N. Li, and L. Liu, Study of Structure and Corrosion Resistance of Fe-Based Amorphous Coatings Prepared by HVAF and HVOF, Corros. Sci., 2011, 53, p 2351-2356.

P. Bansal, P.H. Shipway, and S.B. Leen, Residual Stresses in High-Velocity Oxy-Fuel Thermally Sprayed Coatings-Modelling the Effect of Particle Velocity and Temperature During the Spraying Process, Acta Mater., 2007, 55, p 5089-5101.

C.Y. Lee, T.J. Lin, H.H. Sheu, and H.B. Lee, A Study on Corrosion and Corrosion-Wear Behavior of Fe-Based Amorphous Alloy Coating Prepared by High Velocity Oxygen Fuel Method, J. Mater. Res. Technol., 2021, 15, p 4880-4895.

P. Bijalwan, A. Kumar, S.K. Nayak, A. Banerjee, M. Dutta, and T. Laha, Microstructure and Corrosion Behavior of Fe-Based Amorphous Composite Coatings Developed by Atmospheric Plasma Spraying, J. Alloys Compd., 2019, 796, p 47-54.

X. Liu, Y. Wu, Z. Qiu, Z. Lu, S. Yao, S. Zhuo, and D. Zeng, Simultaneously Enhancing Wear and Corrosion Resistance of HVAF-Sprayed Fe-Based Amorphous Coating from Mo Clad Feedstock, J. Mater. Process. Tech., 2022, 302, p 117465.

D. Liang, Y. Zhou, X. Liu, Q. Zhou, B. Huang, E. Zhang, Q. Chen, and J. Shen, Wettability and Corrosion Performance of Arc-Sprayed Fe-Based Amorphous Coatings, Surf. Coat. Technol., 2022, 423, p 128129.

Y.J. Sun, R. Yang, L. Xie, W.R. Wang, Y.B. Li, S.L. Wang, H.X. Li, J.M. Zhang, and J.S. Zhang, Interfacial Bonding Mechanism and Properties of HVOF-Sprayed Fe-Based Amorphous Coatings on LA141 Magnesium Alloy Substrate, Surf. Coat. Technol., 2021, 426, p 127801.

F.F. Lu, K. Ma, C.X. Li, and C.J. Li, Enhanced Corrosion Resistance of a Double Ceramic Composite Coating Deposited by a Novel Method on Magnesium-Lithium Alloy (LA43M) Substrates, J. Therm. Spray Tech., 2021, 30, p 680-693.

Z.J. Li, Q. Kuang, X.L. Dong, T.W. Yuan, Q.H. Ren, X.X. Wang, J. Wang, and X.Y. Jing, Characteristics of High-Performance Anti-Corrosion/Anti-Wear Ceramic Coatings on Magnesium-Lithium Alloy by Plasma Electrolytic Oxidation Surface Engineering, Surf. Coat. Technol., 2019, 375, p 600-607.

Y.S. Tao, T.Y. Xiong, C. Sun, L.Y. Kong, X.Y. Cui, T.F. Li, and G.L. Song, Microstructure and Corrosion Performance of a Cold Sprayed Aluminium Coating on AZ91D Magnesium Alloy, Corros. Sci., 2010, 52, p 3191-3197.

Z.Y. Cui, F. Ge, Y. Lin, L.W. Wang, L. Lei, H.Y. Tian, M.D. Yu, and X. Wang, Corrosion Behavior of AZ31 Magnesium Alloy in the Chloride Solution Containing Ammonium Nitrate, Electrochim. Acta, 2018, 278, p 421-437.

S. Cui, H.M. Zhai, W.S. Li, X.J. Fan, X.Q. Li, W.C. Ning, and D.S. Xiong, Microstructure and Corrosion Resistance of Fe-Based Amorphous Coating Prepared by Detonation Spray, Surf. Coat. Technol., 2020, 399, p 126096.

M. Wang, Z. Zhou, Q. Wang, L. Wu, Z. Wang, and X. Zhang, Long Term Semiconducting and Passive Film Properties of a Novel Dense FeCrMoCBY Amorphous Coating by Atmospheric Plasma Spraying, Appl. Surf. Sci., 2019, 495, p 143600.

J. Zhou and D. Kong, Immersion Corrosion and Electrochemical Performances of Laser Cladded FeSiB, FeSiBCr and FeSiBCrMo Coatings in 3.5 wt.% NaCl Solution, Surf. Coat. Technol., 2020, 383, p 125229.

S.D. Zhang, J. Wu, W.B. Qi, and J.Q. Wang, Effect of Porosity Defects on the Long-Term Corrosion Behavior of Fe-Based Amorphous Alloy Coated Mild Steel, Corros. Sci., 2016, 110, p 57-70.

M.C. Biesinger, B.P. Payne, A.P. Grosvenor, L.W.M. Lau, A.R. Gerson, and R.S.C. Smart, Resolving Surface Chemical States in XPS Analysis of First Row Transition Metals, Oxides and Hydroxides: Cr, Mn, Fe, Co and Ni, Appl. Surf. Sci., 2011, 257(7), p 2717-2730.

J.J. Si, X.H. Chen, Y.H. Cai, Y.D. Wu, T. Wang, and X.H. Hui, Corrosion Behavior of Cr-Based Bulk Metallic Glasses in Hydrochloric Acid Solutions, Corros. Sci., 2016, 107, p 123-132.

M. Zhao, F. Wei, W.Q. Huang, and Y. Lei, Experimental and Numerical Investigation on Combined Girth Welding of API X80 Pipeline Steel, Sci. Technol. Weld. Join., 2015, 20, p 622-630.

M.P. Singh, R. Kumar, D.K. Shukla, and K.S. Arora, Phase Transformation and Impact Toughness in HAZ of Micro Alloyed X80 Line Pipe Steel, Mater. Res. Express, 2019, 6, p 1-18.

G. Khalaj, H. Yoozbashizadeh, A. Khodabandeh, and M. Tamizifar, Austenite Grain Growth Modelling in Weld Heat Affected Zone of Nb/Ti Microalloyed Linepipe Steel, Mater. Sci. Technol., 2014, 30, p 424-433.

Z.P. Zhao, K. Xu, P.F. Xu, and B. Wang, CO2 Corrosion Behavior of Simulated Heat-Affected Zones for X80 Pipeline Steel, Mater Charact, 2021, 171, p 110772.

X.R. Zhang, J.L. Zhao, T. Xi, M.B. Shahzad, C.G. Yang, and K. Yang, Dissolution and Repair of Passive Film on Cu-Bearing 304L Stainless Steels Immersed in H2SO4 Solution, J. Mater. Sci. Technol., 2018, 34, p 11.

L. Sharma and R. Chhibber, Microstructure Evolution and Electrochemical Corrosion Behaviour of API X70 Linepipe Steel In Different Environments, Int. J. Press. Vessel. Pip., 2019, 171, p 51-59.

M.R.A. Karim, S. Daniel, E.U. Haq, A. Ahmad, K.I. Khan, and S.A. Raza, Improving the Corrosion Resistance of API X56 and API X70 Pipeline Steels by Hot Dip Aluminization, Key Eng. Mater., 2021, 875, p 315-321.

H.H. Zhang, K.W. Gao, L.C. Yan, and X.L. Pang, Inhibition of the Corrosion of X70 and Q235 Steel in CO2-Saturated Brine by Imidazoline-Based Inhibitor, J. Electroanal. Chem., 2017, 791, p 83-94.

Acknowledgements

This research was supported by National Natural Science Foundation of China (Grant No. 52261032, 51861021, 51661016), Science and Technology Plan of Gansu Province (Grant No. 21YF5GA074), Public Welfare Project of Zhejiang Natural Science Foundation (Grant No. LGG22E010008), and Wenzhou Basic Public Welfare Scientific Research Project (G2023020).

Author information

Authors and Affiliations

Contributions

CL analyzed conceptualization, project administration, and writing—original draft. GQ and QZ provide writing and editing and validation. XW performed review and editing and carried out formal analysis. XL and SK conducted review and formal analysis, and approved investigation, review, and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that they do not have any competing financial interests or relationships that made an impact on the study reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Quan, G., Zhang, Q. et al. A Novel Amorphous Alloy Coating for Elevating Corrosion Resistance of X70 Pipeline Steel. J Therm Spray Tech (2024). https://doi.org/10.1007/s11666-024-01778-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11666-024-01778-4