Abstract

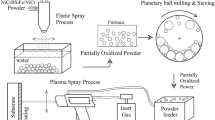

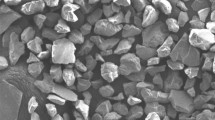

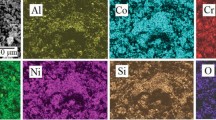

The study investigated the performance of CoCrFeMnNi high entropy alloy and tungsten carbide–nickel coatings under alumina particle impingement. The coatings were applied to 2205 duplex stainless steel substrates by cold spray using nitrogen. For the composite coatings, the amount of WC nanoparticles entrapped in the Ni matrix was estimated as 42.5 ± 8 vol.%. A cold-sprayed interlayer of 316 stainless steel promoted CoCrFeMnNi HEA deposition. Post-process annealing was performed on the coatings. After 3 hours of holding time, x-ray diffraction examination revealed no tungsten decarburization in the WC/Ni-Ni coating. Annealing peak temperatures for the WC/Ni–Ni and high entropy alloy coatings were 600 and 550 °C, respectively. The effect of SS316 annealing on subsequent HEA deposition and coating’s erosion behavior was also investigated. Microhardness tests showed the HEA coating outperforming the WC/Ni-Ni. The coatings were subjected to impact erosion using alumina particles at three different approach angles: 30°, 60°, and 90°. To compare the different materials, average erosion values were calculated expressed in volume loss per grams of erodent. The as-sprayed WC/Ni–Ni was the most effective against 60° impingement angle, while HEA coatings demonstrated promising under impacts at 30° and 90°. Overall, the 30° impact orientation was identified as the most critical condition. Eroded surfaces were examined using optical microscopy (OM) and scanning electron microscopy (SEM).

Similar content being viewed by others

References

C.P. Paul, S.K. Mishra, P. Tiwari and L.M. Kukreja, Solid-Particle Erosion Behaviour of WC/Ni Composite Clad Layers with Different Contents of WC Particles, Opt. Laser Technol., 2013, 50, p 155-162. https://doi.org/10.1016/j.optlastec.2013.03.002

K. Van Acker, D. Vanhoyweghen, R. Persoons and J. Vangrunderbeek, Influence of Tungsten Carbide Particle Size and Distribution on the Wear Resistance of Laser Clad WC/Ni Coatings, Wear, 2005, 258(1–4), p 194-202.

L. Du, B. Xu, S. Dong, W. Zhang, J. Zhang, H. Yang and H. Wang, Sliding Wear Behavior of the Supersonic Plasma Sprayed WC-Co Coating in Oil Containing Sand, Surf. Coatings Technol., 2008, 202(15), p 3709-3714.

J.R.T. Branco, R. Gansert, S. Sampath, C.C. Berndt and H. Herman, Solid Particle Erosion of Plasma Sprayed Ceramic Coatings, Mater. Res., 2004, 7(1), p 147-153.

Y. Lian and Y. Li, Investigation on Erosion Resistance of WC–Co–Cr Coatings, Tribol. Online, 2018, 13(2), p 36-42.

S.G. Sapate, N. Tangselwar, S.N. Paul, R.C. Rathod, S. Mehar, D.S. Gowtam and M. Roy, Effect of Coating Thickness on the Slurry Erosion Resistance of HVOF-Sprayed WC-10Co-4Cr Coatings, J Thermal Spray Technol, 2021, 30, p 1365-1379. https://doi.org/10.1007/s11666-021-01190-2

J. Tang, G.C. Saha, P. Richter, J. Kondás, A. Colella and P. Matteazzi, Effects of Post-Spray Heat Treatment on Hardness and Wear Properties of Ti-WC High-Pressure Cold Spray Coatings, J. Therm. Spray Technol., 2018, 27(7), p 1153-1164.

M. Kazasidis, E. Verna, S. Yin and R. Lupoi, The Effect of Heat Treatment and Impact Angle on the Erosion Behavior of Nickel-Tungsten Carbide Cold Spray Coating Using Response Surface Methodology, Emerg Mater, 2021, 4(6), p 1605-1618.

S.J. McMaster, T.W. Liskiewicz, A. Neville and B.D. Beake, Probing Fatigue Resistance in Multi-Layer DLC Coatings by Micro-and Nano-Impact: Correlation to Erosion Tests, Surf. Coat. Technol., 2020, 402, p 126319. https://doi.org/10.1016/j.surfcoat.2020.126319

N. Okimura, J. Choi, W. Nakayama, N. Ata, Y. Hirata, N. Ohtake and H. Akasaka, Metal Matrix Composites Using Diamond-like Carbon-Coated Particles Fabricated by Cold Spray Technique, J Thermal Spray Technol, 2020, 29, p 1660-1668. https://doi.org/10.1007/s11666-020-01071-0

V.K. Champagne, The Cold Spray Materials Deposition Process: Fundamentals and Applications, The Cold Spray Materials Deposition Process: Fundamentals and Applications, (2007)

G. Motors, S.N. Laborato-, and F.M. Company, Cold Spray Technology, (n.d)

R.T. Sataloff, M.M. Johns, and K.M. Kost, Modern Cold Spray, Springer, (2015)

S. Rahmati, R.G.A. Veiga, A. Zúñiga and B. Jodoin, A Numerical Approach to Study the Oxide Layer Effect on Adhesion in Cold Spray, J. Therm. Spray Technol., 2021, 30(7), p 1777-1791.

S.A. Alidokht and R.R. Chromik, Sliding Wear Behavior of Cold-Sprayed Ni-WC Composite Coatings: Influence OF WC Content, Wear, 2021, 477, p 203792. https://doi.org/10.1016/j.wear.2021.203792

S. Yin, E.J. Ekoi, T.L. Lupton, D.P. Dowling and R. Lupoi, Cold Spraying of WC-Co-Ni Coatings Using Porous WC-17Co Powders: Formation Mechanism, Microstructure Characterization and Tribological Performance, Mater. Des., 2017, 126, p 305-313. https://doi.org/10.1016/j.matdes.2017.04.040

R.G. Rateick, K.R. Karasek, A.J. Cunningham, K.C. Goretta and J.L. Routbort, Solid-Particle Erosion of Tungsten Carbide/Cobalt Cermet and Hardened 440C Stainless Steel-A Comparison, Wear, 2006, 261(7–8), p 773-778.

M. Bromark, P. Hedenqvist, and S. Hogmark, Coated Tool Steels, Science 186187, 189-194 (1995)

E. Bousser, L. Martinu and J.E. Klemberg-Sapieha, Solid Particle Erosion Mechanisms of Protective Coatings for Aerospace Applications, Surf. Coat. Technol., 2014, 257, p 165-181.

I.M. Hutchings, Ductile-Brittle Transitions and Wear Maps for the Erosion and Abrasion of Brittle Materials, J. Phys. D Appl. Phys., 1992, 25(1), p A212-A221.

G.L. Sheldon and I. Finnie, On the Ductile Behavior of Nominally Brittle Materials during Erosive Cutting, J. Manuf. Sci. Eng. Trans. ASME, 1966, 88(4), p 387-392.

J. Menghani, A. Vyas, P. Patel, H. Natu and S. More, Wear, Erosion And Corrosion Behavior of Laser Cladded High Entropy Alloy Coatings–A Review, Mater Today: Proceed, 2021, 38, p 2824-2829. https://doi.org/10.1016/j.matpr.2020.08.763

R.B. Nair, K. Selvam, H.S. Arora, S. Mukherjee, H. Singh and H.S. Grewal, Slurry Erosion Behavior of High Entropy Alloys, Wear, 2017, 386, p 230-238. https://doi.org/10.1016/j.wear.2017.01.020

J. Xu, S. Peng, Z. Li, S. Jiang, Z.H. Xie, P. Munroe and H. Lu, Remarkable Cavitation Erosion–Corrosion Resistance of CoCrFeNiTiMo High-Entropy Alloy Coatings, Corros. Sci., 2021, 190, p 109663. https://doi.org/10.1016/j.corsci.2021.109663

F. Ghadami, M.A. Davoudabadi, and S. Ghadami, Cyclic Oxidation Properties of the Nanocrystalline AlCrFeCoNi High-Entropy Alloy Coatings Applied by the Atmospheric Plasma Spraying Technique. Coatings, 12(3) (2022)

C.J. Akisin, C.J. Bennett, F. Venturi, H. Assadi and T. Hussain, Numerical and Experimental Analysis of the Deformation Behavior of CoCrFeNiMn High Entropy Alloy Particles onto Various Substrates During Cold Spraying, J Thermal Spray Technol, 2022, 31(4), p 1085-1111. https://doi.org/10.1007/s11666-022-01377-1

R. Nikbakht, C.V. Cojocaru, M. Aghasibeig, É. Irissou, T.S. Kim, H.S. Kim and B. Jodoin, Cold Spray and Laser-Assisted Cold Spray of CrMnCoFeNi High Entropy Alloy Using Nitrogen as the Propelling Gas, J. Therm. Spray Technol., 2022, 31(4), p 1129-1142.

J.E. Ahn, Y.K. Kim, S.H. Yoon and K.A. Lee, Tuning the Microstructure and Mechanical Properties of Cold Sprayed Equiatomic CoCrFeMnNi High-Entropy Alloy Coating Layer, Metals Mater Int, 2021, 27, p 2406-2415. https://doi.org/10.1007/s12540-020-00886-4

J. Mahaffey, A. Vackel, S. Whetten, M. Melia and A.B. Kustas, Structure Evolution and Corrosion Performance of CoCrFeMnNi High Entropy Alloy Coatings Produced Via Plasma Spray and Cold Spray, J Thermal Spray Technol, 2022, 31(4), p 1143-1154.

Z. Zeng, M. Xiang, D. Zhang, J. Shi, W. Wang, X. Tang and K. Morita, Mechanical Properties of Cantor Alloys Driven by Additional Elements: A Review, J Mater Res Technol, 2021, 15, p 1920-1934. https://doi.org/10.1016/j.jmrt.2021.09.019

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler and E.P. George, The Influences of Temperature and Microstructure on the Tensile Properties of a CoCrFeMnNi High-Entropy Alloy, Acta Mater., 2013, 61(15), p 5743-5755.

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan and A. Hohenwarter, Mechanical Properties, Microstructure and Thermal Stability of a Nanocrystalline CoCrFeMnNi High-Entropy Alloy after Severe Plastic Deformation, Acta Mater., 2015, 96, p 258-268.

L. Baiamonte, G. Pulci, A. Gisario, L. Paglia, A.L. Marino, M. Tului and F. Marra, WC-Ti Coatings Deposited Via Cold Gas Spray and Modified by Laser and Furnace Heat Treatments, J Thermal Spray Technol, 2021, 30, p 2083-2098. https://doi.org/10.1007/s11666-021-01278-9

S.A. Alidokht, P. Vo, S. Yue and R.R. Chromik, Cold Spray Deposition of Ni and WC-Reinforced Ni Matrix Composite Coatings, J. Therm. Spray Technol., 2017, 26(8), p 1908-1921.

ISO 113581, International Standard ITeh Standard ITeh Standard Preview, Int. Organ. Stand., p 3-6 (2015)

C. Wei, Z. Liu, Y. Bao, D. Wan, Y. Qiu and X. Liu, Evaluating Thermal Expansion Coefficient and Density of Ceramic Coatings by Relative Method, Mater. Lett., 2015, 161, p 542-544. https://doi.org/10.1016/j.matlet.2015.09.034

H.Z. Li, J. Wang and J.M. Fan, Analysis and Modelling of Particle Velocities in Micro-Abrasive Air Jet, Int J Machine Tools Manuf, 2009, 49(11), p 850-858. https://doi.org/10.1016/j.ijmachtools.2009.05.012

B.J. Connolly, E. Loth and C.F. Smith, Drag and Bounce of Irregular Particles and Test Dust, AIAA Propuls. Energy Forum Expo., 2019, 2019(363), p 275-285.

Astm, G76-07, Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets, ASTM Int., pp 1-6 (2013)

R.C. Dykhuizen and M.F. Smith, Gas Dynamic Principles of Cold Spray, J. Therm. Spray Technol., 1998, 7(2), p 205-212.

M. Grujicic, C.L. Zhao, C. Tong, W.S. DeRosset and D. Helfritch, Analysis of the Impact Velocity of Powder Particles in the Cold-Gas Dynamic-Spray Process, Mater. Sci. Eng. A, 2004, 368(1–2), p 222-230.

S. Yin, M. Meyer, W. Li, H. Liao and R. Lupoi, Gas Flow, Particle Acceleration, and Heat Transfer in Cold Spray: A Review, J Thermal Spray Technol, 2016, 25, p 874-896.

A.P. Alkhimov, V.F. Kosarev and S.V. Klinkov, The Features of Cold Spray Nozzle Design, J. Therm. Spray Technol., 2001, 10(2), p 375-381.

V.K. Champagne, D.J. Helfritch, S.P.G. Dinavahi and P.F. Leyman, Theoretical and Experimental Particle Velocity in Cold Spray, J. Therm. Spray Technol., 2011, 20(3), p 425-431.

W.Y. Li, H. Liao, G. Douchy and C. Coddet, Optimal Design of a Cold Spray Nozzle by Numerical Analysis of Particle Velocity and Experimental Validation with 316L Stainless Steel Powder, Mater. Des., 2007, 28(7), p 2129-2137.

W. Li, H. Assadi, F. Gaertner and S. Yin, A Review of Advanced Composite and Nanostructured Coatings by Solid-State Cold Spraying Process, Critic Rev Solid State Mater Sci, 2019, 44(2), p 109-156. https://doi.org/10.1080/10408436.2017.1410778

S. Özbilen, Satellite Formation Mechanism in Gas Atomized Powders, Powder Metall., 1999, 42(1), p 70-78.

S.A. Alidokht, P. Vo, S. Yue and R.R. Chromik, Erosive Wear Behavior of Cold-Sprayed Ni-WC Composite Coating, Wear, 2017, 376, p 566-577. https://doi.org/10.1016/j.wear.2017.01.052

Y. Qian and Z. Zhao, Microstructure and Properties of Ultrafine Cemented Carbides Prepared by Microwave Sintering of Nanocomposites, Crystals, 2020, 10(6), p 507.

M. Kazasidis, E. Verna, S. Yin, and R. Lupoi, Investigation of the Effect of Low-Temperature Annealing and Impact Angle on the Erosion Performance of Nickel-Tungsten Carbide Cold Spray Coating Using Design of Experiments. In ITSC2022 (pp 763-772). ASM International

S. Yin, X.F. Wang, W.Y. Li and H.E. Jie, Effect of Substrate Hardness on the Deformation Behavior of Subsequently Incident Particles in Cold Spraying, Appl. Surf. Sci., 2011, 257(17), p 7560-7565.

S. Bagherifard, J. Kondas, S. Monti, J. Cizek, F. Perego, O. Kovarik and M. Guagliano, Tailoring Cold Spray Additive Manufacturing of Steel 316 L for Static and Cyclic Load-Bearing Applications, Mater. Des., 2021, 203, p 109575. https://doi.org/10.1016/j.matdes.2021.109575

S. Yin, J. Cizek, X. Yan and R. Lupoi, Annealing Strategies for Enhancing Mechanical Properties of Additively Manufactured 316L Stainless Steel Deposited by Cold Spray, Surf. Coat. Technol., 2019, 370, p 353-361. https://doi.org/10.1016/j.surfcoat.2019.04.012

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu and R. Lupoi, Deposition of FeCoNiCrMn High Entropy Alloy (HEA) Coating via Cold Spraying, J. Mater. Sci. Technol., 2019, 35(6), p 1003-1007. https://doi.org/10.1016/j.jmst.2018.12.015

S.A. Alidokht, J. Lengaigne, J.E. Klemberg-Sapieha, S. Yue and R.R. Chromik, Effect of Microstructure and Properties of Ni-WC Composite Coatings on Their Solid Particle Erosion Behavior, J. Mater. Eng. Perform., 2019, 28, p 1532-1543. https://doi.org/10.1007/s11665-019-03956-w

H. Oettel and R. Wiedemann, Residual Stresses in PVD Hard Coatings, Surf Coatings Technol, 1995, 76, p 265-273. https://doi.org/10.1016/0257-8972(95)02581-2

T. Suhonen, T. Varis, S. Dosta, M. Torrell and J.M. Guilemany, Residual Stress Development in Cold Sprayed Al Cu and Ti Coatings, Acta Mater., 2013, 61(17), p 6329-6337. https://doi.org/10.1016/j.actamat.2013.06.033

S.H. Zahiri, C.I. Antonio, and M. Jahedi, Elimination of Porosity in Directly Fabricated Titanium via Cold Gas Dynamic Spraying, (2008)

Acknowledgments

The authors express their appreciation to SchuF Valve Technology GmbH and ESA for their financial support (Grant: 4000137618/22/NL/GLC/idb). Special thanks are extended to Trinity College Dublin's CRANN Advanced Microscopy Laboratory (AML) for their valuable assistance in microscopy characterization and analysis. This project received additional backing from the EU Commission Recovery and Resilience Facility through the Science Foundation Ireland Future Digital Challenge Grant Number 22/NCF/FD/10827. Support was also provided by Science Foundation Ireland under Grant 18/EPSRC-CDT-3581 and the Engineering and Physical Sciences Research Council (EPSRC) Grant EP/S023259/1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited paper selected from presentations at the 2023 International Thermal Spray Conference, held May 22–25, 2023, in Québec City, Canada, and has been expanded from the original presentation. The issue was organized by Giovanni Bolelli, University of Modena and Reggio Emilia (Lead Editor); Emine Bakan, Forschungszentrum Jülich GmbH; Partha Pratim Bandyopadhyay, Indian Institute of Technology, Karaghpur; Šárka Houdková, University of West Bohemia; Yuji Ichikawa, Tohoku University; Heli Koivuluoto, Tampere University; Yuk-Chiu Lau, General Electric Power (Retired); Hua Li, Ningbo Institute of Materials Technology and Engineering, CAS; Dheepa Srinivasan, Pratt & Whitney; and Filofteia-Laura Toma, Fraunhofer Institute for Material and Beam Technology.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cappelli, G., Sasnauskas, A., Yin, S. et al. Erosion Behavior of Cold-Sprayed Coatings Made of CoCrFeMnNi HEA and Tungsten Carbide Nanoparticles in a Nickel Matrix. J Therm Spray Tech 33, 471–488 (2024). https://doi.org/10.1007/s11666-023-01710-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01710-2