Abstract

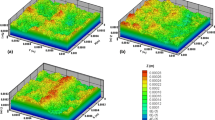

The main focus of this study is on simulation of coating formation on substrates with arbitrary shapes. For this purpose, several substrate geometries shaped as inclined step, cylinder and sphere are considered. The stress analysis for these complex coating geometries is also performed. The formation of Nickel coatings on various shapes of stainless-steel substrates and Yttria-Stabilized Zirconia (YSZ) on NiCrAlY in the atmospheric plasma spray (APS) process is investigated. The topography of the coatings, as well as their microstructure, e.g., porosity, average thickness and average roughness, are evaluated. An algorithm, which is based on the Monte-Carlo stochastic model, is employed in this work. The parameters of the droplets impacting the surface, including their velocity, temperature and size, are predicted through the use of this stochastic model. Simulation results show that on the inclined part of the step or peripheral parts of the cylinder/sphere, the coating porosity is considerably lower than the flat parts, while the roughness is remarkably higher. A significant difference between the coating temperature and that of the substrate leads to the formation of residual thermal stresses. These stresses are analyzed using the object oriented finite-element (OOF) software, which utilizes an adaptive meshing technique and finite-element method to calculate residual thermal stresses. The maximum stress in the coatings occurs at the interface between the coating and the substrate. The coatings' topography and microstructure are compared with those of the experiments.

Similar content being viewed by others

Abbreviations

- C :

-

Specific heat; stiffness tensor

- d :

-

Diameter of splat

- D :

-

Diameter of droplet

- f :

-

Volume fraction

- F :

-

External forces in linear elastic theory; cumulative probability distribution function

- g :

-

Probability density function

- h :

-

Thickness

- H f :

-

Latent heat of fusion

- K :

-

Stiffness tensor

- P :

-

Porosity

- R A :

-

Average surface roughness

- S :

-

Random variate

- t :

-

Time

- T :

-

Temperature

- U :

-

Gun speed

- u :

-

Displacement vector

- V :

-

Particle speed

- c :

-

Coating

- cell :

-

Cell

- e :

-

Equivalent

- el :

-

Elastic

- g :

-

Gap

- gun :

-

Gun

- i :

-

Discretized x-direction

- j :

-

Discretized y-direction

- k :

-

Discretized z-direction

- m :

-

Material

- mat :

-

Material

- max:

-

Maximum

- sub:

-

Substrate

- x :

-

Orthogonal coordinate

- y :

-

Orthogonal coordinate

- z :

-

Orthogonal coordinate

- α :

-

Thermal expansion factor

- γ :

-

Surface tension

- δ :

-

Liquid–solid contact angle

- ε :

-

Strain tensor

- η :

-

Dummy variable

- λ :

-

Thermal diffusivity

- μ :

-

Mean value of probability density function

- ν :

-

Kinematic viscosity

- ξ :

-

Spread factor

- ρ :

-

Density

- σ :

-

Standard deviation of probability density function; stress in linear elastic theory

- Pe:

-

Peclet number \(\left( {{\text{Pe}} = {\raise0.7ex\hbox{${{\text{VD}}}$} \!\mathord{\left/ {\vphantom {{{\text{VD}}} \lambda }}\right.\kern-0pt} \!\lower0.7ex\hbox{$\lambda $}}} \right)\)

- Re:

-

Reynolds number \(\left( {{\text{Re}} = {\raise0.7ex\hbox{${VD}$} \!\mathord{\left/ {\vphantom {{VD} \nu }}\right.\kern-0pt} \!\lower0.7ex\hbox{$\nu $}}} \right)\)

- Ste:

-

Stefan number \(\left( {{\text{Ste}} - = {\raise0.7ex\hbox{${C\left( {T - T_{{{\text{sub}}}} } \right)}$} \!\mathord{\left/ {\vphantom {{C\left( {T - T_{{{\text{sub}}}} } \right)} {H_{f} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${H_{f} }$}}} \right)\)

- We:

-

Weber number \(\left( {{\text{We}} = {\raise0.7ex\hbox{${\rho V^{2} D}$} \!\mathord{\left/ {\vphantom {{\rho V^{2} D} \gamma }}\right.\kern-0pt} \!\lower0.7ex\hbox{$\gamma $}}} \right)\)

References

A. Feuerstein et al., Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: A Review, J. Therm. Spray Technol., 2008, 17(2), p 199-213.

G. Barbezat, Advanced Thermal Spray Technology and Coating for Lightweight Engine Blocks for the Automotive Industry, Surf. Coat. Technol., 2005, 200(5), p 1990-1993.

B. Jahani, F. Azarmi, and A. Brooks, Development of Antibacterial Surfaces Via Thermal Spray Coating Techniques, Biomed. Sci. Instrum., 2018, 54, p 116-122.

D. Jia et al., Splat Formation Mechanism of Droplet-Filled Cold-Textured Groove During Plasma Spraying, Appl. Therm. Eng., 2020, 173, 115239.

P. Xu et al., Superhydrophobic Ceramic Coatings with Lotus Leaf-like Hierarchical Surface Structures Deposited via Suspension Plasma Spray Process, Surf. Interf., 2023, 38, 102780.

J. Mostaghimi et al., Thermal Spray Copper Alloy Coatings as Potent Biocidal and Virucidal Surfaces, J. Therm. Spray Technol., 2021, 30(1), p 25-39.

L. Pershin, et al. Copper-Embedded Facemasks for the Destruction of Covid-19 and Other Pathogens. in International Thermal Spray Conference (ITSC). 2022. Vienna, Austria.

M. Pasandideh-Fard et al., Deposition of tin Droplets on a Steel Plate: Simulations and Experiments, Int. J. Heat Mass Transf., 1998, 41(19), p 2929-2945.

M. Bussmann, J. Mostaghimi, and S. Chandra, On a Three-Dimensional Volume Tracking Model of Droplet Impact, Phys. Fluids, 1999, 11(6), p 1406-1417.

M. Pasandideh-Fard, S. Chandra, and J. Mostaghimi, A Three-Dimensional Model of Droplet Impact and Solidification, Int. J. Heat Mass Transf., 2002, 45(11), p 2229-2242.

R. Ghafouri-Azar et al., A Stochastic Model to Simulate the Formation of a Thermal Spray Coating, J. Therm. Spray Technol., 2003, 12(1), p 53-69.

M. Xue, S. Chandra, and J. Mostaghimi, Investigation of Splat Curling up in Thermal Spray Coatings, J. Therm. Spray Technol., 2006, 15(4), p 531-536.

M. Xue et al., Formation of Pores in Thermal Spray Coatings Due to Incomplete Filling of Crevices in Patterned Surfaces, Plasma Chem. Plasma Process., 2007, 27(5), p 647-657.

M. Xue et al., A Stochastic Coating Model to Predict the Microstructure of Plasma Sprayed Zirconia Coatings, Modell. Simul. Mater. Sci. Eng., 2008, 16(6), 065006.

H.B. Parizi et al., Analysis of the Microstructure of Thermal Spray Coatings: A Modeling Approach, J. Therm. Spray Technol., 2010, 19(4), p 736-744.

Mahendru, P., M. Tembely, and A. Dolatabadi, Artificial Intelligence Models for Analyzing Thermally Sprayed Functional Coatings. J. Therm. Spray Technol. 2023.

J. García et al., In-situ High Temperature Stress Analysis of Ti(C, N) Coatings on Functionally Graded Cemented Carbides by Energy Dispersive Synchrotron X-ray Diffraction, Int. J. Refract Metal Hard Mater., 2016, 56, p 27-34.

X.C. Zhang et al., An Analytical Model for Predicting Thermal Residual Stresses in Multilayer Coating Systems, Thin Solid Films, 2005, 488(1-2), p 274-282.

S. Langer, E. Fuller, and W. Carter, OOF: An Image-Based Finite-Element Analysis of Material Microstructures, Comput. Sci. Eng., 2001, 3, p 15-23.

C.-H. Hsueh et al., Effects of Interface Roughness on Residual Stresses in Thermal Barrier Coatings, J. Am. Ceram. Soc., 1999, 82(4), p 1073-1075.

R. Ghafouri-Azar, J. Mostaghimi, and S. Chandra, Modeling Development of Residual Stresses in Thermal Spray Coatings, Comput. Mater. Sci., 2006, 35(1), p 13-26.

M. Friis et al., Investigation of Particle in-Flight Characteristics During Atmospheric Plasma Spraying of Yttria-Stabilized ZrO2: Part 1 Experimental, J. Therm. Spray Technol., 2001, 10(2), p 301-310.

S.D. Aziz and S. Chandra, Impact, Recoil and Splashing of Molten Metal Droplets, Int. J. Heat Mass Transf., 2000, 43(16), p 2841-2857.

R. Ghafouri-Azar, et al. Numerical Simulation of Offset Deposition for Sequential Tin Droplets. in International Thermal Spray Conference (ITSC). 2002. Essen, Germany.

S. Safai and H. Herman, Microstructural Investigation of Plasma-Sprayed Aluminum Coatings, Thin Solid Films, 1977, 45(2), p 295-307.

H. Fukanuma, A Porosity Formation and Flattening Model of an Impinging Molten Particle in Thermal Spray Coatings, J. Therm. Spray Technol., 1994, 3(1), p 33-44.

H.R. Salimijazi et al., Measuring Substrate Temperature Variation During Application of Plasma-Sprayed Zirconia Coatings, J. Therm. Spray Technol., 2007, 16(4), p 580-587.

K.A. Khor and Y.W. Gu, Thermal Properties of Plasma-Sprayed Functionally Graded Thermal Barrier Coatings, Thin Solid Films, 2000, 372(1), p 104-113.

T.G. Kollie, Measurement of the Thermal-Expansion Coefficient of Nickel from 300 to 1000 K and Determination of the Power-law Constants Near the Curie Temperature, Phys. Rev. B, 1977, 16(11), p 4872-4881.

A. Farrokhpanah, T.W. Coyle, and J. Mostaghimi, Numerical Study of Suspension Plasma Spraying, J. Therm. Spray Technol., 2016, 26(1-2), p 12-36.

J. Mostaghimi, M. Pasandideh-Fard, and S. Chandra, Dynamics of Splat Formation in Plasma Spray Coating Process, Plasma Chem. Plasma Process., 2002, 22(1), p 59-84.

H. Chien, The Effects of Microstructural and Thermal Stresses on the Hardness of CVD Deposited α‐Al2O3 and TiCxN(1‐x) Coatings, in Materials Science and Engineering. 2011, Carnegie Mellon University: Pittsburgh, PA, USA

S.V. Raj et al., High Heat Flux Exposures of Coated GRCop-84 Substrates, Mater. Sci. Eng. A, 2007, 457(1-2), p 300-312.

J.A. Ruud et al., A New Method for Tensile Testing of Thin Films, J. Mater. Res., 1993, 8(1), p 112-117.

P. Pathak, et al. Contribution in Optimization of Honeycomb Abradable Seals Structure. in International Thermal Spray Conference (ITSC). 2021.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited paper selected from presentations at the 2023 International Thermal Spray Conference, held May 22–25, 2023, in Québec City, Canada, and has been expanded from the original presentation. The issue was organized by Giovanni Bolelli, University of Modena and Reggio Emilia (Lead Editor); Emine Bakan, Forschungszentrum Jülich GmbH; Partha Pratim Bandyopadhyay, Indian Institute of Technology, Karaghpur; Šárka Houdková, University of West Bohemia; Yuji Ichikawa, Tohoku University; Heli Koivuluoto, Tampere University; Yuk-Chiu Lau, General Electric Power (Retired); Hua Li, Ningbo Institute of Materials Technology and Engineering, CAS; Dheepa Srinivasan, Pratt & Whitney; and Filofteia-Laura Toma, Fraunhofer Institute for Material and Beam Technology.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Haghighi, B., Passandideh-Fard, M. & Mostaghimi, J. Modeling the Formation of Thermal Spray Coatings on Substrates with Arbitrary Shapes. J Therm Spray Tech 33, 551–571 (2024). https://doi.org/10.1007/s11666-023-01691-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01691-2