Abstract

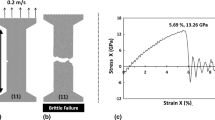

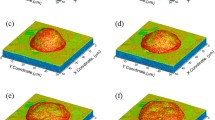

Several related aerosol processes utilize a supersonic gas jet to impact solid nanoparticles to produce nanograined films. Although the influence of important control variables such as particle size and particle impact velocity on particle deformation and film formation for these processes have been previously studied, other variables have not been systematically explored. One parameter that cannot be controlled in experiments is the particle impact orientation. Because particles impact with a full range of crystallographic orientations, an understanding of the effect of particle orientation is required to predict film microstructures. In this study, molecular dynamics simulations were conducted with Ag to determine the influence of particle crystallographic orientation on the deformation experienced by the particle upon impact and the resulting microstructure of the deposit. It is shown that the orientations that produce the largest overall particle deformation are not correlated to orientations where the initiation of plastic deformation is easiest, as one might expect. Rather, the deformation experienced by the particle is heterogeneous and depends on the mechanisms responsible for deformation. Two deformation mechanisms are identified: (1) dislocation plasticity and (2) disordering followed by viscous flow. The fraction of the atoms in the impacting particle that experience deformation by each mechanism is quantified as a function of particle orientation. The implications of the effects of particle crystallographic orientation on film microstructures are also discussed.

Similar content being viewed by others

Availability of Data

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

S. Kashu, E. Fuchita, T. Manabe, and C. Hayashi, Deposition of Ultra Fine Particles Using a Gas Jet, Jpn. J. Appl. Phys., 1984, 23, p L910-L912.

M. Oda, E. Fuchita, M. Tsuneizumi, S. Kashu, and C. Hayashi, Gas Deposition Films of Ultra Fine Particles, Nanostruct. Mater., 1992, 1, p 203-206.

W.T. Nichols, G. Malyavanatham, M.P. Beam, D.E. Henneke, J.R. Brock, M.F. Becker, and J.W. Keto, Synthesis of Nanostructured WC Films by Supersonic Impaction of Nanoparticle Aerosols, MRS Symp. Proc., 2000, 581, p 193-198.

W.T. Nichols, D.T. O’Brien, G. Malyavanatham, M.F. Becker, and J.W. Keto, Supersonic Nanocrystal Deposition for Nanostructured Materials, MRS Symp. Proc., 2002, 703, p 209-214.

C. Huang, W.T. Nichols, D.T. O’Brien, M.F. Becker, J.W. Keto, and D. Kovar, Supersonic Jet Deposition of Silver Nanoparticle Aerosols: Correlations of Impact Conditions and Film Morphologies, J. Appl. Phys., 2007, 101, p 064902.

M. Nahar, J.W. Keto, M.F. Becker, and D. Kovar, Highly Conductive Nanoparticulate Films Achieved at Low Processing Temperatures, J. Electron. Mater., 2015, 44, p 2559-2565.

J.J.H. McCallister, J.W. Keto, M.F. Becker, and D. Kovar, Influence of Normal Velocity on Microstructure and Density of Films Produced by Nanoparticle Impact, AIP Adv., 2019, 9(3), p 035226.

H. Haberland, Z. Insepov, M. Karrais, M. Mall, M. Moseler, and Y. Thurner, Thin Film Growth by Energetic Cluster Impact (ECI): Comparison Between Experiment and Molecular Dynamics Simulations, Mater. Sci. Eng. B, 1993, 19, p 31-36.

H. Ogawa, Molecular Dynamics Simulation on the Single Particle Impacts in the Aerosol Deposition Process, Mater. Trans., 2005, 46(6), p 1235-1239.

J. Tarus and K. Nordlund, Molecular Dynamics Study on Si20 Cluster Deposition on Si(0 0 1), Nucl. Instrum. Methods Phys. Res. B, 2003, 212, p 281-285.

H. Zhu and R.S. Averback, Molecular Dynamics Simulation of Densification Processes in Nanocrystalline Materials, Mater. Sci. Eng., 1995, A204, p 96-100.

H. Jami and A. Jabbarzadeh, Unravelling Ultrafast Deformation Mechanisms in Surface Deposition of Titanium Nanoparticles, Appl. Surf. Sci., 2019, 489, p 446-461.

T.V. Chitrakar, J.W. Keto, M.F. Becker, and D. Kovar, Particle Deposition and Deformation from High Speed Impaction of Ag Nanoparticles, Acta Mater., 2017, 135, p 252-262.

T.V. Chitrakar, G.J.J. Noiseau, J.W. Keto, M.F. Becker, and D. Kovar, An Experimental and Computational Study of High-Speed Impact of Ag Nanoparticles, J. Appl. Phys., 2019, 125, p 195104.

W.D. Callister and D.G. Rethwisch, Materials Science and Engineering: An Introduction, Wiley, New York, 2010.

S. Plimpton, Fast Parallel Algorithms for Short-Range Molecular Dynamics, J. Comput. Phys., 1995, 117, p 1-19.

P.L. Williams, Y. Mishin, and J.C. Hamilton, An Embedded-atom Potential for the Cu-Ag System, Model. Simul. Mater. Sci. Eng., 2006, 14(5), p 817-833.

W. Shinoda, M. Shiga, and M. Mikami, Rapid Estimation of Elastic Constants by Molecular Dynamics Simulation Under Constant Stress, Phys. Rev. B, 2004, 69(13), p 134103.

A. Stukowski, Visualization and Analysis of Atomistic Simulation Data with OVITO—The Open Visualization Tool, Modelling Simul. Mater. Sci. Eng., 2010, 18, p 015012.

P.M. Larsen, S. Schmidt, and J. Schiøtz, Robust Structural Identification via Polyhedral Template Matching, Model. Simul. Mater. Sci., 2016, 24(5), p 055007.

D. Hull and D.J. Bacon, Introduction to Dislocations, 5th ed. Butterworth-Heinemann, Oxford, 2011.

M.F. Becker and D. Kovar, A Quantitative Criterion for Predicting Solid-State Disordering During High Strain Rate Deformation, J. Phys. Condens. Matter, 2020, 33(6), p 065405.

M.F. Becker and D. Kovar, A Quantitative Criterion for Predicting Solid-state Disordering During Biaxial, High Strain Rate Deformation, Model. Simul. Mater. Sci., 2021, 30(1), p 015006.

T.V. Chitrakar, M.F. Becker, and D. Kovar, A Quantitative Criterion to Predict Atomic Disordering During High Velocity Nanoparticle Impact, J. Aerosol Sci., 2022, 165, p 106042.

Acknowledgments

This work was supported by the National Science Foundation under Grant No. CMMI 2102818. The authors acknowledge the Texas Advanced Computing Center (TACC) at The University of Texas at Austin for providing HPC resources that have contributed to the research results reported within this paper. URL: http://tacc.utexas.edu.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chitrakar, T.V., Becker, M.F. & Kovar, D. Influence of Crystallographic Orientation on the Deformation of Ag Nanoparticles During High-Speed Impact. J Therm Spray Tech 32, 2683–2700 (2023). https://doi.org/10.1007/s11666-023-01664-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01664-5