Abstract

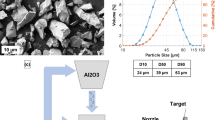

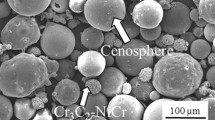

Extreme erosion wear from elevated temperature caused by the impact of entrained solid particles in the fluid stream primarily affects aerospace components and marine parts. This work focuses on increasing the base material erosion resistance by applying thermally sprayed carbide-based coatings. A high-temperature Solid particle erosion behavior of WC-Co/NiCr/Mo and Cr3C2-CoNiCrAlY coatings deposited by the HVOF process on a titanium-31 was evaluated using an air-jet erosion tester. The erosion test was conducted utilizing alumina erodent of grit size 35-50 µm. The effects of impact angles (30°, 60°, and 90°) and temperatures (200-800 °C) on the erosion performance of two coatings are compared. The feedstock powder and as-sprayed coatings were characterized for micro-structure phase composition, porosity, density, micro-hardness, and adhesion strength. SEM/EDS and a 3D optical profilometer were used to examine eroded samples further to determine the erosion mode. The Cr3C2-CoNiCrAlY coating shows a brittle mode behavior of erosion at 200-400 °C and ductile mode behavior of erosion at 600-800 °C. In contrast, the WC-Co/NiCr/Mo coating shows brittle mode behavior of erosion at 200-400 °C and 600-800 °C, a mixed mode behavior of erosion. The erosion loss in volume of Cr3C2-CoNiCrAlY is lower than WC-Co/NiCr/Mo for all temperatures and impact angles. The development of carbide and oxide phases on the eroded surfaces demonstrates increasing erosion resistance at high temperatures. The optical profilometer measures the volumetric erosion loss, compares it with the weight loss method, and finds consistency between them.

Similar content being viewed by others

References

D.G. Bhosale, T.R. Prabhu, W.S. Rathod, M.A. Patil and S.W. Rukhande, High Temperature Solid Particle Erosion Behaviour of SS 316L and Thermal Sprayed WC-Cr3C2-Ni Coatings, Wear, 2020, 462-463(October), p 203520.

T.K. Mishra, A. Kumar and S.K. Sinha, Experimental Investigation and Study of HVOF Sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr Coating on Its Sliding Wear Behaviour, Int. J. Refract. Met. Hard Mater., 2021, 94(October 2020), p 105404.

S. Harsha, D.K. Dwivedi and A. Agrawal, Influence of WC Addition in Co-Cr-W-Ni-C Flame Sprayed Coatings on Microstructure, Microhardness and Wear Behaviour, Surf. Coat. Technol., 2007, 201(12), p 5766-5775.

E. Hao, X. Zhao, Y. An, W. Deng, Y. Ren, H. Zhou and J. Chen, WC-Co Reinforced NiCoCrAlYTa Composite Coating: Effect of the Proportion on Microstructure and Tribological Properties, Int. J. Refract. Met. Hard Mater., 2019, 84(June), p 104978.

N. Chavana, V.F. Bhajantri and S.C. Jambagi, Improvement in Slurry Erosion and Corrosion Resistance of Plasma-Sprayed Fly Ash Coatings for Marine Applications, ACS Omega, 2022, 7(36), p 32369-32382.

G. Nath and S. Kumar, Studies on Slurry Erosion Behavior of HVOF Applied Y2O3-Added WC-10Co-4Cr Cermet on 13-4 Martensitic Stainless Steel, Metallogr. Microstruct. Anal., 2018, 7, p 133-142.

I. El Azhari, J. García, M. Zamanzade, F. Soldera, C. Pauly, C. Motz, L. Llanes and F. Mücklich, Micromechanical Investigations of CVD Coated WC-Co Cemented Carbide by Micropillar Compression, Mater. Des., 2020, 186, p 108283. https://doi.org/10.1016/j.matdes.2019.108283

D. Kazlauskas, V. Jankauskas, R. Kreivaitis and S. Tučkutė, Wear Behaviour of PVD Coating Strengthened WC-Co Cutters during Milling of Oak-Wood, Wear, 2022, 498-499(March), p 204336.

N. Purushotham, N.L. Parthasarathi, P.S. Babu, G. Sivakumar and B. Rajasekaran, Effect of Thermal Expansion on the High Temperature Wear Resistance of Ni-20%Cr Detonation Spray Coating on IN718 Substrate, Surf. Coat. Technol., 2023, 462(April), p 129490. https://doi.org/10.1016/j.surfcoat.2023.129490

N. Purushotham, B. Rajasekaran, N.L. Parthasarathi, K. Praveen and G. Sivakumar, Sliding Wear Behaviour of Ni-5 %Al Coating Deposited by Detonation Spray on IN718, Mater. Today Proc., 2022, 65, p 3741-3747. https://doi.org/10.1016/j.matpr.2022.06.425

Y. Hu, Z. Wang and M. Pang, Effect of WC Content on Laser Cladding Ni-Based Coating on the Surface of Stainless Steel, Mater. Today Commun., 2022, 31, p 103357.

Š Houdková, F. Zahálka, M. Kašparová and L.M. Berger, Comparative Study of Thermally Sprayed Coatings under Different Types of Wear Conditions for Hard Chromium Replacement, Tribol. Lett., 2011, 43(2), p 139-154.

G. Bolelli, L.M. Berger, T. Börner, H. Koivuluoto, V. Matikainen, L. Lusvarghi, C. Lyphout, N. Markocsan, P. Nylén, P. Sassatelli, R. Trache and P. Vuoristo, Sliding and Abrasive Wear Behaviour of HVOF- and HVAF-Sprayed Cr3C2-NiCr Hardmetal Coatings, Wear, 2016, 358, p 32-50.

M. Xie, S. Zhang and M. Li, Comparative Investigation on HVOF Sprayed Carbide-Based Coatings, Appl. Surf. Sci., 2013, 273, p 799-805. https://doi.org/10.1016/j.apsusc.2013.03.010

K. Szymański, A. Hernas, G. Moskal and H. Myalska, Thermally Sprayed Coatings Resistant to Erosion and Corrosion for Power Plant Boilers—A Review, Surf. Coat. Technol., 2015, 268, p 153-164.

M. Akhtari Zavareh, A.A.D.M. Sarhan, B.B. Razak and W.J. Basirun, The Tribological and Electrochemical Behavior of HVOF-Sprayed Cr3C2-NiCr Ceramic Coating on Carbon Steel, Ceram. Int., 2015, 41(4), p 5387-5396. https://doi.org/10.1016/j.ceramint.2014.12.102

S. Mahade, A. Mulone, S. Björklund, U. Klement and S. Joshi, Investigating Load-Dependent Wear Behavior and Degradation Mechanisms in Cr3C2-NiCr Coatings Deposited by HVAF and HVOF, J. Mater. Res. Technol., 2021, 15, p 4595-4609.

Z. Geng, S. Li, D.L. Duan and Y. Liu, Wear Behaviour of WC-Co HVOF Coatings at Different Temperatures in Air and Argon, Wear, 2015, 330-331, p 348-353.

G. Bolelli, L. Berger, M. Bonetti and L. Lusvarghi, Comparative Study of the Dry Sliding Wear Behaviour of HVOF-Sprayed WC-(W, Cr) 2C-Ni and WC-CoCr Hardmetal Coatings, Wear, 2014, 309(1-2), p 96-111. https://doi.org/10.1016/j.wear.2013.11.001

V. Sreenivasulu and M. Manikandan, High-Temperature Corrosion Behaviour of Air Plasma Sprayed Cr3C2-25NiCr and NiCrMoNb Powder Coating on Alloy 80A at 900 °C, Surf. Coat. Technol., 2018, 337(October 2017), p 250-259. https://doi.org/10.1016/j.surfcoat.2018.01.011

K. Yuan, R. Lin Peng, X.H. Li and S. Johansson, Hot Corrosion Behavior of HVOF-Sprayed CoNiCrAlYSi Coatings in a Sulphate Environment, Vacuum, 2015, 122, p 47-53. https://doi.org/10.1016/j.vacuum.2015.09.015

J. Du, F. Li, Y. Li, H. Lu, X. Qi, B. Yang, C. Li, P. Yu and Y. Cao, High Temperature Oxidation Behavior and Interface Diffusion of Cr3C2-NiCrCoMo/Nano-CeO2 Composite Coatings, J. Alloys Compd., 2022, 905, p 164177. https://doi.org/10.1016/j.jallcom.2022.164177

J. Du, F. Li, Y. Li, H. Lu, X. Qi, B. Yang, C. Li, P. Yu, J. Wang and L. Gao, The Influence of Nano-CeO2 on Tribological Properties and Microstructure Evolution of Cr3C2-NiCrCoMo Composite Coatings at High Temperature, Surf. Coat. ings Technol., 2021, 428(November), p 127913. https://doi.org/10.1016/j.surfcoat.2021.127913

C. Zhang, L. Liu, H. Xu, J. Xiao, G. Zhang and H. Liao, Role of Mo on Tribological Properties of Atmospheric Plasma-Sprayed Mo-NiCrBSi Composite Coatings under Dry and Oil-Lubricated Conditions, J. Alloys Compd., 2017, 727, p 841-850.

P. Niranatlumpong and H. Koiprasert, Surface & Coatings Technology the Effect of Mo Content in Plasma-Sprayed Mo-NiCrBSi Coating on the Tribological Behavior, Surf. Coat. Technol., 2010, 205(2), p 483-489. https://doi.org/10.1016/j.surfcoat.2010.07.017

R.J.K. Wood, Tribology of Thermal Sprayed WC-Co Coatings, Int. J. Refract. Met. Hard Mater., 2010, 28(1), p 82-94. https://doi.org/10.1016/j.ijrmhm.2009.07.011

T.S. Sidhu, A. Malik, S. Prakash and R.D. Agrawal, Oxidation and Hot Corrosion Resistance of HVOF WC-NiCrFeSiB Coating on Ni- and Fe-Based Superalloys at 800 °C, J. Therm. Spray Technol., 2007, 16(5-6), p 844-849.

G. Bolelli, I. Hulka, H. Koivuluoto, L. Lusvarghi, A. Milanti, K. Niemi and P. Vuoristo, Properties of WC-FeCrAl Coatings Manufactured by Different High Velocity Thermal Spray Processes, Surf. Coat. Technol., 2014, 247, p 74-89. https://doi.org/10.1016/j.surfcoat.2014.03.021

J.A. Picas, M. Punset, S. Menargues, E. Martín and M.T. Baile, Microstructural and Tribological Studies of As-Sprayed and Heat-Treated HVOF Cr3C2-CoNiCrAlY Coatings with a CoNiCrAlY Bond Coat, Surf. Coat. Technol., 2015, 268, p 317-324.

M. Mathapati, M.R. Ramesh and M. Doddamani, High Temperature Erosion Behavior of Plasma Sprayed NiCrAlY/WC-Co/Cenosphere Coating, Surf. Coat. Technol., 2017, 325, p 98-106. https://doi.org/10.1016/j.surfcoat.2017.06.033

N. Krishnamurthy, M.S. Murali, B. Venkataraman and P.G. Mukunda, Characterization and Solid Particle Erosion Behavior of Plasma Sprayed Alumina and Calcia-Stabilized Zirconia Coatings on Al-6061 Substrate, Wear, 2012, 274-275, p 15-27. https://doi.org/10.1016/j.wear.2011.08.003

H.S. Sidhu, B.S. Sidhu and S. Prakash, Comparative Characteristic and Erosion Behavior of NiCr Coatings Deposited by Various High-Velocity Oxyfuel Spray Processes, J. Mater. Eng. Perform., 2006, 15(6), p 699-704.

H. Zhang, X. Dong and S. Chen, Solid Particle Erosion-Wear Behaviour of Cr3C2-NiCr Coating on Ni-Based Superalloy, Adv. Mech. Eng., 2017, 9(3), p 1-9.

S.R. Medabalimi, M.R. Ramesh and R. Kadoli, High-Temperature Solid Particle Erosion Behavior of Partially Oxidized NiCrBSiFe/NiCr Plasma Spray Coatings, J. Therm. Spray Technol., 2021, 30(6), p 1638-1652.

B. Somasundaram, B.C. Navinesh and N. Jegadeeswaran, Erosion Behaviour of HVOF Sprayed WC. Co-NiCrAlYSi (35%-65%) Coatings, Mater. Today: Proc., 2021, 45, p 372-376.

M. Subba Rao, M.R. Ramesh and K. Ravikiran, Solid Particle Erosion Behavior of Partially Oxidized Al with NiCr Composite Coating at Elevated Temperature, J. Mater. Eng. Perform., 2021, 30(5), p 3749-3760.

G. Yang, C. Li, S. Zhang and C. Li, High-Temperature Erosion of HVOF Sprayed Cr3C2-NiCr Coating and Mild Steel for Boiler Tubes, J. Therm. Spray Technol., 2008, 17(December), p 782-787.

C. Huang, L. Du and W. Zhang, Friction and Wear Characteristics of Plasma-Sprayed Self-Lubrication Coating with Clad Powder at Elevated Temperatures up to 800 °C, J. Therm. Spray Technol., 2014, 23(3), p 463-469.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Behera, N., Medabalimi, S. & Ramesh, M.R. Effect of Impact Angles and Temperatures on the Solid Particle Erosion Behavior of HVOF Sprayed WC-Co/NiCr/Mo and Cr3C2-CoNiCrAlY Coatings. J Therm Spray Tech 32, 2411–2425 (2023). https://doi.org/10.1007/s11666-023-01654-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01654-7