Abstract

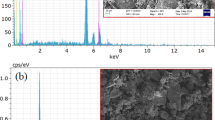

In order to investigate the experimental characteristics of Fe-based cladded layers obtained by laminar plasma cladding, Fe-based cladded layers on Q235 steel were prepared by using a homemade laminar plasma cladding system. Then, the characteristics of the Fe-based layers were measured and discussed in order to explore the cladding mechanism of Fe-based powder on the surface of Q235 steel. Experimental results show that the substrate was mainly composed of equiaxed ferrite and fine-grained pearlite, while the heat-affected zone was composed of coarse grains and the cladded layer of acicular ferrite and (Fe, Cr)x(C, B)y. The cladded layer was mainly composed of α-(Fe, Ni) and (Cr, Fe)7(C,B)3 phases, which could improve the hardness of the cladded layer up to 600 HV0.2. The average friction coefficients of the substrate and cladded layer were around 0.20 and 0.14, respectively, showing that the cladded layer has greater wear resistance.

Similar content being viewed by others

References

Y. Xiang, D. Yu, Q. Li, H. Peng, X. Cao, and J. Yao, Effects of Thermal Plasma Jet Heat Flux Characteristics on Surface Hardening, J. Mater. Process. Tech., 2015, 226, p 238-246.

M.M. Quazi, M.A. Fazal, A.S.M.A. Haseeb, F. Yusof, H.H. Masjuki, and A. Arslan, A Review to the Laser Cladding Of Self-Lubricating Composite Coatings, Lasers Manuf. Mater. Process., 2016, 3, p 1-33.

Z. Wu, T. Li, Q. Li, B. Shi, X. Li, X. Wang, H. Lu, and H. Zhang, Process Optimization of Laser Cladding Ni60A Alloy Coating in Remanufacturing, Opt. Laser Technol., 2019, 120, p 105718.

J.B. Liu and L.M. Wang, Wear Resistance of Fe-Cr-C-TiFe Fe-Based Composite Coating Prepared by Precursor Carbonization-Composition Process and Plasma Cladding, Mater. Sci. Forum, 2011, 704-705, p 1237-1243.

J. Yuan, Q. Wang, X. Liu, S. Lou, and Z. Wang, Microstructures and High-Temperature Wear Behavior of NiAl/WC-Fex Coatings on Carbon Steel by Plasma Cladding, J. Alloy Compd., 2020, 842, p 155850.

C. Zhao, F. Tian, H.R. Peng, and J.Y. Hou, Non-Transferred Arc Plasma Cladding of Stellite Ni60 Alloy on Steel, Surf. Coat. Tech., 2002, 155, p 80-84.

J. Pu, P. Xie, W. Long, M. Wu, Y. Sheng, and J. Sheng, Effect of Current on Corrosion Resistance of Duplex Stainless Steel Layer Obtained by Plasma Arc Cladding, Crystals, 2022, 12, p 341.

A. Zx, Z.A. Chao, A. Rw, L.A. Dan, A. Yz, A. Gl, and A. Xl, Microstructure and Wear Resistance of WC/Co-Based Coating on Copper by Plasma Cladding, J. Market. Res., 2022, 15, p 821-833.

S. Zhang, M. Lei, M. Wan, and C. Huang, Morphology, Hardness and Wear Properties of Plasma Cladding NiCrCu Coating on M2 High-Speed Steel, Coatings, 2020, 10, p 641.

M. Tang, J. Wang, Z. Feng, G. Li, Z. Yan, and R. Zhang, Corrosion Resistance of AlN and Fe3Al Reinforced Fe-Based Plasma Cladding Layer in 3.5 wt% NaCl Solution, Ceram. Int., 2019, 45, p 16918-16926.

X. Deng, G. Zhang, T. Wang, S. Ren, Z. Bai, and Q. Cao, Investigations on Microstructure and Wear Resistance of Fe-Mo Alloy Coating Fabricated by Plasma Transferred Arc Cladding, Surf. Coat. Tech., 2018, 350, p 480-487.

M.Q. Wang, Z.H. Zhou, L.T. Wu, Y. Ding, and Z.H. Wang, Characterization and In-Situ Formation Mechanism of Tungsten Carbide Reinforced Fe-Based Alloy Coating by Plasma Cladding, Int. J. Miner. Metall. Mater., 2018, 25, p 439-443.

Y. Hu, J. Wan, Y. Lei, Z. Tian, J. Cao, L. Feng, X. Cheng, X. Jie, and H. Zhang, Influence of the Phase Composition and Microstructure of Plasma Cladding Fe-Cr-Ni-C Alloy Coating on Residual Stress and Crack Formation, Int. J. Adv. Manuf. Tech., 2018, 96(5), p 1607-1613.

J. Lu, B. Wang, X. Qiu, Z. Peng, and M. Ma, Microstructure Evolution and Properties of CrCuFexNiTi High-Entropy Alloy Coating by Plasma Cladding on Q235, Surf. Coat. Technol., 2017, 328, p 313-318.

Z.X. Wang, L. Qian, and W.T. Yang, Study of Plasma Cladding Ni-Based Compound Powder Layers on Q235 Steel, Appl. Mech. Mater., 2012, 174-177, p 219-222.

X. Cao, D. Yu, Y. Xiang, C. Li, H. Jiang, and J. Yao, Study on the Ignition Process of a Segmented Plasma Torch, Plasma Sci. Technol., 2017, 19, p 63-70.

X. Cao, C. Li, R. He, H. Xu, L. Chen, and B. Huang, Study on the Influences of the Anode Structures on the Jet Characteristics of a Laminar Plasma Torch, Plasma Res. Express, 2020, 2, p 18001.

X. Cao, C. Li, L. Chen, and B. Huang, Experimental Study on the Design and Characteristics of a Laminar Plasma Torch With Medium Working Power and its Applications for Surface Hardening, IEEE Trans. Plasma Sci., 2020, 48, p 961-968.

X. Cao and L. Chen, Design and Characteristics of a New Type Laminar Plasma Torch for Materials Processing, Plasma Sci. Technol., 2019, 22, p 402-410.

Acknowledgment

The authors appreciate the supports of the Yibin Science and Technology Plan Project (No. 2021JC002), the Fundamental Research Funds for the Central Universities, CHD (No. 300102252502), the Key Laboratory of Mechanical Structure Optimization & Material Application Technology of Luzhou (No. SCHYZSA-2022-02) and the Key Laboratory of Intelligent Manufacturing of Construction Machinery Project (No.IMCM202103). We also thank Adam Brotchie, PhD, from Liwen Bianji (Edanz) (www.liwenbianji.cn), for editing the English text of a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, X., Wang, L., He, R. et al. Characterization of Fe-Based Layers Deposited by Laminar Plasma Cladding on Low-Carbon Steel. J Therm Spray Tech 32, 2104–2111 (2023). https://doi.org/10.1007/s11666-023-01634-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01634-x