Abstract

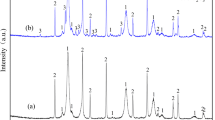

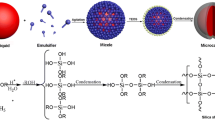

Core-shell CaF2@ZrO2 powders were prepared by sol method combined with centrifugal atomization drying, aiming at preventing CaF2 from burning during the APS deposition of YSZ-based abradable seal coating. The microstructure, chemical composition, hardness and wear behavior of the YSZ coating, the YSZ-10CaF2 coating and the YSZ-10CaF2@ZrO2 coating were comparatively investigated. The results suggested that the core-shell powders effectively protected CaF2, where the amount of CaF2 remained in the YSZ-10CaF2@ZrO2 coating was higher than that in the YSZ-10CaF2 coating. The YSZ coating had the highest average hardness of 97.3 HR45Y and exhibited a mixed wear mechanism of adhesive and fatigue wear with a friction coefficient of 0.23 and a volume wear rate of 7.28 mm3/N m. Contributed to soft and self-lubricating CaF2, the hardness of the YSZ-10CaF2 and YSZ-10CaF2@ZrO2 coatings slightly declined to 95.1 and 94.5 HR45Y correspondingly. The YSZ-10CaF2 coating showed a mixed wear mechanism of abrasive and fatigue wear with a friction coefficient of 0.14 and a volume wear rate of 4.67 mm3/N m. Moreover, the YSZ-10CaF2@ZrO2 coatings showed a mixed wear mechanism of reduced adhesive and fatigue wear with a friction coefficient of 0.10 and a volume wear rate of 2.66 mm3/N m.

Similar content being viewed by others

References

E. Irissou, A. Dadouche, and R.S. Lima, Tribological Characterization Of Plasma-Sprayed CoNiCrAlY-BN Abradable Coatings, J. Therm. Spray Technol., 2014, 23(1-2), p 252-261.

B.X. Zhang and M. Marshall, Investigating the Application of a Honeycomb Abradable Lining in the Turbine Stage of an Aero-Engine, Tribol. Int., 2018, 125, p 66-74.

C. Belebarre, V. Wagner, J.Y. Paris, G. Dessein, J. Denape, and J. Gurt-Santanach, Tribological Characterization of a Labyrinth-Abradable Interaction in a Turbo Engine Application, Wear, 2017, 370-371, p 29-38.

W. Deng, X.Q. Zhao, Y.L. An, E.K. Hao, S.J. Li, H.D. Zhou, and J.M. Chen, Improvement of Tribological Properties of as-Sprayed 8ysz coatings by In-Situ Synthesis C/MoS2 Composite Lubricant, Tribol. Int., 2018, 128, p 260-270.

N.P. Padture, Advanced Structural Ceramics in Aerospace Propulsion, Nat. Mater., 2016, 15(8), p 804-809.

S.Y. Tao, B. Liang, C.X. Ding, H.L. Liao, and C. Coddet, Wear Characteristics of Plasma-Sprayed Nanostructured Yttria Partially Stabilized Zirconia Coatings, J. Therm. Spray Technol., 2005, 14(4), p 518-523.

S.J. Li, X.Q. Zhao, Y.L. An, D.D. Liu, H.D. Zhou, and J.M. Chen, YSZ/MoS2 Self-Lubricating Coating Fabricated by Thermal Spraying and Hydrothermal Reaction, Ceram. Int., 2018, 44(15), p 17864-17872.

R. Ali, T.H. Huang, P. Song, D.F. Zhang, S. Ali, M. Arif, S. Awais, D. Hanifi, and J.S. Lu, Tribological Performance and Phase Transition of MAX-Phase/YSZ Abradable Seal Coating Produced by Air Plasma Spraying, Ceram. Int., 2022, 48(3), p 4188-4199.

X.Q. Zhao, S.J. Li, G.L. Hou, Y.L. An, H.D. Zhou, and J.M. Chen, Influence of Doping Graphite on Microstructure and Tribological Properties of Plasma Sprayed 3Al2O3–2SiO2 Coating, Tribol. Int., 2016, 101, p 168-177.

J. Yang, Y.J. Zhang, X.Q. Zhao, Y.L. An, H.D. Zhou, J.M. Chen, and G.L. Hou, Tribological Behaviors of Plasma Sprayed CuAl/Ni-Graphite Composite Coating, Tribol. Int., 2015, 90, p 96-103.

J.J. Tian, S.W. Yao, X.T. Luo, C.X. Li, and C.J. Li, An Effective Approach for Creating Metallurgical Self-Bonding in Plasma-Spraying of NiCr-Mo Coating by Designing Shell-Corestructured Powders, Acta. Mater., 2016, 110, p 19-30.

H.S. Chae, S.D. Kim, S.H. Piao, and H.J. Choi, Core-shell Structured Fe3O4@SiO2 Nanoparticles Fabricated by Sol–gel Method and Their Magnetorheology, Colloid Polym. Sci., 2016, 294(4), p 647-655.

P.P. Chen, Z.H. Cheng, F.X. Chu, Y.Z. Xu, and C.P. Wang, Fabrication of Polyacrylate Core–Shell Nanoparticles Via Spray Drying Method, J. Nanopart. Res., 2016, 18(5), p 1-10.

S.A. Azzez, Z. Hassan, and J.J. Hassan, Identification and Characteristics of core–shell ZnO/ZnO:MgNanorods Synthesized by Hydrothermal Method, J. Mater. Sci: Mater. Electron., 2016, 27(12), p 12618-12626.

L.G. Jia, Z.Q. Chen, R.X. Guo, C.H. Xu, and N.S. Guo, Preparation of Nano-Coating Powder CaF2@Al(OH)3 and Its Application in Al2O3/Ti(C, N) Self-Lubricating Ceramic Tool Materials, Ceram. Int., 2020, 46(10), p 15949-15957.

G.F. Zhang, G.C. Xiao, Z.Q. Chen, N.S. Guo, C.H. Xu, M.D. Yi, J.J. Zhang, and T.T. Zhou, A New Preparation Method of CaF2@SiO2 Nano Solid Lubricant and Analysis of Its Coating Mechanism, J. Alloys Compd., 2021, 883, p 160795.

X.D. Cheng, H.Y. Xiang, W.P. Ye, X.M. Meng, J. Min, M.Z. Liu, P. Zhang, and W. Lu, Effect of Coated PHB on Properties of Abradable Seal Coating, J. Wuhan Univ. Technol.-Mater. Sci. E, 2014, 29(3), p 417-421.

Y. Mansill, M.D. Arce, C. Gonzalez-Oliver, J. Basbus, H. Troiani, and A. Serquis, Characterization of Stabilized ZrO2 Thin Films Obtained by Sol-Gel Method, Appl. Surf. Sci., 2021, 569, p 150787.

S. Tsunekawa, Y. Kawazoe, T. Kojima, and T. Sugimoto, Fabrication of Zirconium Oxide Nanocrystallites and the Critical Size of the Phase Transition, Int. J. Nanosci., 2006, 5(4&5), p 651-656.

N.V. Dorkar, Y.-W. Kim, and B.V.M. Kumar, Influence of Temperature, Impact Angle and h-BN Content on the Erosivewear Behavior of Hot-Pressed SiC-BN Composites, Wear, 2020, 458-459, p 203447.

D.D. Qin, Y.R. Niu, H. Li, X. Zhong, X.B. Zheng, and J.L. Sun, Fabrication and Characterization of Yb2Si2O7-Based Composites as Novel Abradable Sealing Coatings, Ceram. Int., 2021, 47(16), p 23153-23161.

T.H. Le, Y.H. Chae, and S.S. Kim, Sliding Wear Behavior of Plasma Sprayed Zirconia Coating on Cast Aluminum Against Silicon Carbide Ceramic, J. Mater. Sci. Technol., 2005, 21(5), p 666-670.

G.Y. Wu, C.H. Xu, G.C. Xiao, M.D. Yi, Z.Q. Chen, and L.H. Xu, Self-Lubricating Ceramic Cutting Tool Material With the Addition of Nickel Coated CaF2 Solid Lubricant Powders, Int. J. Refract. Met. Hard Mater., 2016, 56, p 51-58.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant No. 52006159).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, X., Xiong, Y., Liu, Z. et al. Preparation and Characterization of Self-Lubricating CaF2@ZrO2/YSZ Composite Coating. J Therm Spray Tech 31, 2126–2135 (2022). https://doi.org/10.1007/s11666-022-01424-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01424-x