Abstract

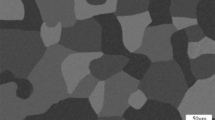

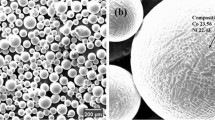

The superior corrosion resistance of high-entropy alloys (HEA) has attracted much attention from researchers in recent years. In this study, with minor additions of passivation elements into a CoCrFeNi matrix, a (CoCrFeNi)94Ti1.5Al4.5 HEA coating was prepared by a plasma cladding method. This coating has a single FCC phase structure and uniform microstructure, which is expected to form a uniform and compact passive film on the corrosion surface. After adding Ti and Al elements, the passive film became more compact due to the decrease in the proportion of porous hydroxide, which increased the impedance of the passive film, thereby improving the corrosion resistance of the whole HEA coating. After potentiostatic polarization for 4 h, a stable passive film was formed on the (CoCrFeNi)94Ti1.5Al4.5 coating surface in a 0.5-M H2SO4 solution. The corrosion current density was only 175 nA/cm2, which was much lower than that of 304 stainless steel and pure titanium. This indicated that minor additions of Ti and Al can promote the formation of corrosion-resistant high-performance passive films without forming deleterious second phases, and that this phenomenon is more obvious in sulfuric acid solution than in hydrochloric acid solution.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375-377, p 213-218.

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299-303.

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448-511.

Y.A. Alshataif, S. Sivasankaran, F.A. Al-Mufadi, A.S. Alaboodi and H.R. Ammar, Manufacturing Methods, Microstructural and Mechanical Properties Evolutions of High-Entropy Alloys: A Review, Met. Mater. Int., 2020, 26(8), p 1099-1133.

W. Li, P. Liu and P.K. Liaw, Microstructures and Properties of High-Entropy Alloy Films and Coatings: A Review, Mater. Res. Lett., 2018, 6(4), p 199-229.

W.R. Zhang, P.K. Liaw and Y. Zhang, Science and Technology in High-Entropy Alloys, Sci. China Mater., 2018, 61(1), p 2-22.

D.X. Hao, N.N. Zhang, Y. Zhang and D.Y. Li, Effect of Vanadium Addition on Microstructure and Properties of Al0.5Cr0.9FeNi2.5 Multi-Principal Alloys, J. Iron Steel Res. Int., 2021, 28, p 586-596.

B.Q. Jin, N.N. Zhang, Y. Zhang and D.Y. Li, Microstructure, Phase Composition and Wear Resistance of Low Valence Electron Concentration AlxCoCrFeNiSi High-Entropy Alloys Prepared by Vacuum Arc Melting, J. Iron Steel Res. Int., 2021, 28, p 181-189.

W.J. Hao, R.L. Sun, W. Niu, X.L. Li, M. Gu and R.Y. Zuo, Study on Microstructure and Corrosion Resistance of CoCrFeNiSix High-Entropy Alloy Coating by Laser Cladding, Surf. Technol., 2021, 50(8), p 343-348.

Y.Z. Shi, B. Yang and P.K. Liaw, Corrosion-Resistant High-Entropy Alloys: A Review, Metals, 2017, 7, p 43.

Y. Qiu, M.A. Gibson, H.L. Fraser and N. Birbilis, Corrosion Characteristics of High Entropy Alloys, Mater. Sci. Technol., 2015, 31(10), p 1235-1243.

Q. Wang, A. Amar, C.L. Jiang, H.W. Luan, S.F. Zhao, H. Zhang, G.M. Le, X. Liu, X.Y. Wang, X.S. Yang and J.F. Li, CoCrFeNiMo0.2 High Entropy Alloy by Laser Melting Deposition: Prospective Material for Low Temperature and Corrosion Resistant Applications, Intermetallics, 2020, 119, p 106727.

Y. Shi, B. Yang, X. Xie, J. Brechtl, K.A. Dahmen and P.K. Liaw, Corrosion of AlxCoCrFeNi High-Entropy Alloys: Al-content and Potential Scan-rate Dependent Pitting Behavior, Corros. Sci., 2017, 119(5), p 33-45.

Y. Fu, C.D. Dai, H. Luo, D.Y. Li, C.W. Du and X.G. Li, The Corrosion Behavior and Film Properties of Al-Containing High-Entropy Alloys in Acidic Solutions, Appl. Surf. Sci., 2021, 506, p 149854.

S.J. Zheng, Z.B. Cai, J.B. Pu, C. Zeng and L.P. Wang, Passivation Behavior of VAlTiCrSi Amorphous High-Entropy Alloy Film with a High Corrosion-Resistance in Artificial Sea Water, Appl. Surf. Sci., 2021, 542, p 148520.

H.X. Cheng, Z.M. Pan, Y. Fu, X.F. Wang, Y. Wei, H. Luo and X.G. Li, Corrosion-Resistant High-Entropy Alloy Coatings: A Review, J. Electrochem. Soc., 2021, 168, p 111502.

Z.L. Xu, H. Zhang, X.J. Du, Y.Z. He, H. Luo, G.S. Song, L. Mao, T.W. Zhou and L.L. Wang, Corrosion Resistance Enhancement of CoCrFeMnNi High-Entropy Alloy Fabricated by Additive Manufacturing, Corros. Sci., 2020, 177, p 108954.

K. Yamanaka, H. Shiratori, M. Mori, K. Omura, T. Fujieda, K. Kuwabara and A. Chiba, Corrosion Mechanism of an Equimolar AlCoCrFeNi High-Entropy Alloy Additively Manufactured by Electron Beam Melting, npj Mater. Degrad., 2020, 4(1), p 24.

S.F. Sun, H. Liu, J.B. Hao and H.F. Yang, Microstructural Evolution and Corrosion Behavior of CoCrFeNiAlxMn Dual-Phase High-Entropy Alloy Coatings Prepared by Laser Cladding, J. Alloys Compd., 2021, 886, p 161251.

C. Cui, M.P. Wu, X.J. Miao, Z.S. Zhao and Y.L. Gong, Microstructure and Corrosion Behavior of CeO2/FeCoNiCrMo High-Entropy Alloy Coating Prepared by Laser Cladding, J. Alloys Compd., 2021, 890, p 161826.

Y.Y. Ge, J.B. Cheng, X.Y. Wang, L. Xue, S.S. Zhu, B.S. Zhang, S. Hong, Y.P. Wu, X.C. Zhang and X.B. Liang, Formation and Properties of Superhydrophobic Al Coatings on Steel, ACS Omega, 2021, 6, p 18383-18394.

H.F. Zhang, C.H. Zhang, Z.Y. Wang, X. Cui, S. Zhang and H.T. Chen, Microstructure and Corrosion Behaviour of WC/NiCrBSi Coatings by Vacuum Cladding, Mater. Sci. Technol., 2022, 38(1), p 19-29.

Y. Fu, J. Li, H. Luo, C.W. Du and X.G. Li, Recent Advances on Environmental Corrosion Behavior and Mechanism of High-Entropy Alloys, J. Mater. Sci. Technol., 2021, 80, p 217-233.

Y.Z. Shi, L. Collins, R. Feng, C. Zhang, N. Balke, P.K. Liaw and B. Yang, Homogenization of AlxCoCrFeNi High-Entropy Alloys with Improved Corrosion Resistance, Corros. Sci., 2018, 133, p 120-131.

Y.Y. Ge, J.B. Cheng, C. Yan, L. Xue, B.S. Zhang and X.B. Liang, Devitrification and Sliding Wear Behaviors of AlFeSi Metallic Glass Coatings, J. Mater. Res. Technol., 2021, 15, p 7022-7032.

Z.Z. Niu, Y.Z. Wang, C. Geng, J. Xu and Y. Wang, Microstructural Evolution, Mechanical and Corrosion Behaviors of as-Annealed CoCrFeNiMox (x = 0, 0.2, 0.5, 0.8, 1) High Entropy Alloys, J. Alloys Compd., 2020, 820, p 153273.

Z. Tang, M.C. Gao, H.Y. Diao, T.F. Yang, J.P. Liu, T.T. Zuo, Y. Zhang, Z.P. Lu, Y.Q. Cheng, Y.W. Zhang, K.A. Dahmen, P.K. Liaw and T. Egami, Aluminum Alloying Effects on Lattice Types, Microstructures, and Mechanical Behavior of High-Entropy Alloys Systems, JOM, 2013, 65(12), p 1848-1858.

P. Muangtong, A. Rodchanarowan, D. Chaysuwan, N. Chanlek and R. Goodall, The Corrosion Behaviour of CoCrFeNi-x (x = Cu, Al, Sn) High Entropy Alloy Systems in Chloride Solution, Corros. Sci., 2020, 172, p 108740.

C.P. Lee, C.C. Chang, Y.Y. Chen, J.W. Yeh and H.C. Shih, Effect of the Aluminium Content of AlxCrFe1.5MnNi0.5 High-Entropy Alloys on the Corrosion Behaviour in Aqueous Environments, Corros. Sci., 2008, 50(7), p 2053-2060.

J.Y. Pang, T. Xiong, X.X. Wei, Z.W. Zhua, B. Zhang, Y.T. Zhou, X.H. Shao, Q.Q. Jin, S.J. Zheng and X.L. Ma, Oxide MnCr2O4 Induced Pitting Corrosion in High Entropy Alloy CrMnFeCoNi, Materialia, 2019, 6, p 100275.

Y.Z. Shi, J.K. Mo, F.Y. Zhang, B. Yang, P.K. Liaw and Y. Zhao, In-situ Visualization of Corrosion Behavior of AlxCoCrFeNi High-Entropy Alloys During Electrochemical Polarization, J. Alloys Compd., 2020, 844, p 156014.

V. Firouzdor, K. Sridharan, G. Cao, M. Anderson and T.R. Allen, Corrosion of a Stainless Steel and Nickel-Based Alloys in High Temperature Supercritical Carbon Dioxide Environment, Corros. Sci., 2013, 69, p 281-291.

P.D. Krell, S.X. Li and H.B. Cong, Synergistic Effect of Temperature and HCl Concentration on the Degradation of AISI 410 Stainless Steel, Corros. Sci., 2017, 122, p 41-52.

J.B. Jorcin, M.E. Orazemb, N. Pebere and B. Tribollet, CPE Analysis by Local Electrochemical Impedance Spectroscopy, Electrochim. Acta, 2006, 51, p 1473-1479.

Q.T. Song and J. Xu, (TiZrNbTa)90Mo10 High-Entropy Alloy: Electrochemical Behavior and Passive Film Characterization Under Exposure to Ringer’s Solution, Corros. Sci., 2020, 167, p 108513.

B. Hirschorna, M.E. Orazema, B. Tribollet, V. Vivier, I. Frateur and M. Musiani, Determination of Effective Capacitance and Film Thickness from Constant-Phase-Element Parameters, Electrochim. Acta, 2010, 55, p 6218-6227.

Z.Y. Cui, L.W. Wang, H.T. Ni, W.K. Hao, C. Man, S.S. Chena, X. Wang, Z.Y. Liu and X.G. Li, Influence of Temperature on the Electrochemical and Passivation Behavior of 2507 Super Duplex Stainless Steel in Simulated Desulfurized Flue Gas Condensates, Corros. Sci., 2017, 118, p 31-48.

L. Wang, C.F. Dong, C. Man, D.C. Kong, K. Xiao and X.G. Li, Enhancing the Corrosion Resistance of Selective Laser Melted 15–5PH Martensite Stainless Steel via Heat Treatment, Corros. Sci., 2020, 166, p 108427.

W.R. Wang, W. Qi, L. Xie, X. Yang, J.T. Li and Y. Zhang, Microstructure and Corrosion Behavior of (CoCrFeNi)95Nb5 High-Entropy Alloy Coating Fabricated by Plasma Spraying, Materials, 2019, 12, p 694.

Acknowledgments

This work was financially supported by Natural Science Foundation of Liaoning Province (No. 2019-MS-247), Liao Ning Revitalization Talents Program (XLYC1807178), Scientific Research Funding Project of the Education Department of Liaoning Province (LJKZ0117), National Natural Science Foundation of China (No. 52001216).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xing, B., Ding, Q., Jin, B. et al. Corrosion Resistance and Passivation Behavior of CoCrFeNi-TiAl High-Entropy Alloy Coatings in Acidic Solutions. J Therm Spray Tech 31, 1673–1682 (2022). https://doi.org/10.1007/s11666-022-01380-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01380-6