Abstract

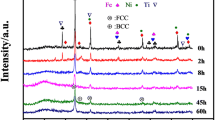

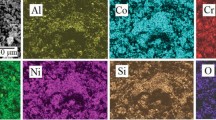

In this study, Al0.5CoCrFeNi2Ti0.5 high-entropy alloy (HEA) powders were prepared by the gas atomization method. The sieved powders with particle sizes of 10-60 and 60-120 µm gas-atomized powders were chosen for further analysis and coatings’ application processes. The as-obtained powders possessed spherical shape and uniform element distribution with an initial FCC structure with a minor BCC phase. The as-atomized powders were annealed at 1000 °C temperature for varying durations and characterized to determine their stable state properties. After annealed at 10000 °C, the metastable BCC phase disappeared and Al0.5CoCrFeNi2Ti0.5 transformed into solid-solution FCC matrix with minor BCC precipitates. The Vickers hardness of the plasma-sprayed coatings showed an increasing trend from 285.3 to 396.7 HV as the current was raised from 500 to 750 A, respectively. Cold-sprayed coatings were performed on both carbon steel and aluminum alloy AA 6061, and their properties were analyzed. The obtained hardness of 426.6 HV was about 10% higher than the plasma-sprayed coatings. Plasma-sprayed coating properties can be varied with plasma power and size of the powder particles. Mechanical locking effect enhanced the bond strength in cold-sprayed AA 6061 compared to carbon substrate. Improved mechanical properties in this alloy were due to precipitation hardening after titanium addition.

Similar content being viewed by others

References

J. Yeh, S. Chen, J. Gan, S. Lin and T. Chin, Formation of Simple Crystal Structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V Alloys with Multiprincipal Metallic, Elements, 2004, 2010(35), p 2533-2536.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater. Sci., 2014, 61, p 1-93. https://doi.org/10.1016/j.pmatsci.2013.10.001

A. Manzoni, H. Daoud, R. Völkl, U. Glatzel and N. Wanderka, Phase Separation in Equiatomic AlCoCrFeNi High-Entropy Alloy, Ultramicroscopy, 2013, 132, p 212-215. https://doi.org/10.1016/j.ultramic.2012.12.015

P.D. Niu, R.D. Li, T.C. Yuan, S.Y. Zhu, C. Chen, M.B. Wang and L. Huang, Microstructures and Properties of an Equimolar AlCoCrFeNi High Entropy Alloy Printed by Selective Laser Melting, Intermetallics, 2019, 104, p 24-32. https://doi.org/10.1016/j.intermet.2018.10.018

V. Shivam, J. Basu, V.K. Pandey, Y. Shadangi and N.K. Mukhopadhyay, Alloying Behaviour, Thermal Stability and Phase Evolution in Quinary AlCoCrFeNi High Entropy Alloy, Adv. Powder Technol., 2018, 29(9), p 2221-2230. https://doi.org/10.1016/j.apt.2018.06.006

Q.H. Li, T.M. Yue, Z.N. Guo and X. Lin, Microstructure and Corrosion Properties of AlCoCrFeNi High Entropy Alloy Coatings Deposited on AISI 1045 Steel by the Electrospark Process, Metall. Mater. Trans. A, 2013, 44(4), p 1767-1778. https://doi.org/10.1007/s11661-012-1535-4

K.-C. Cheng, J.-H. Chen, S. Stadler and S.-H. Chen, Properties of Atomized AlCoCrFeNi High-Entropy Alloy Powders and Their Phase-Adjustable Coatings Prepared via Plasma Spray Process, Appl. Surf. Sci., 2019, 478, p 478-486. https://doi.org/10.1016/j.apsusc.2019.01.203

J.-T. Liang, K.-C. Cheng, Y.-C. Chen, S.-M. Chiu, C. Chiu, J.-W. Lee and S.-H. Chen, Comparisons of Plasma-Sprayed and Sputtering Al0.5CoCrFeNi2 High-Entropy Alloy Coatings, Surf. Coatings Technol., 2020, 403, p 126411. https://doi.org/10.1016/j.surfcoat.2020.126411

W.-R. Wang, W.-L. Wang, S.-C. Wang, Y.-C. Tsai, C.-H. Lai and J.-W. Yeh, Effects of Al Addition on the Microstructure and Mechanical Property of AlxCoCrFeNi High-Entropy Alloys, Intermetallics, 2012, 26, p 44-51. https://doi.org/10.1016/j.intermet.2012.03.005

M. López Ríos, P.P. Socorro Perdomo, I. Voiculescu, V. Geanta, V. Crăciun, I. Boerasu, and J.C. Mirza Rosca, Effects of Nickel Content on the Microstructure, Microhardness and Corrosion Behavior of High-Entropy AlCoCrFeNix Alloys, Sci. Rep., 2020, 10(1), 21119

M. Wu, K. Chen, Z. Xu and D.Y. Li, Effect of Ti Addition on the Sliding Wear Behavior of AlCrFeCoNi High-Entropy Alloy, Wear, 2020, 462-463, 203493. https://doi.org/10.1016/j.wear.2020.203493

G.-S. Ham, Y.-K. Kim, Y.S. Na and K.-A. Lee, Effect of Ti Addition on the Microstructure and High-Temperature Oxidation Property of AlCoCrFeNi High-Entropy Alloy, Met. Mater. Int., 2021, 27(1), p 156-165. https://doi.org/10.1007/s12540-020-00708-7

Z. Xu, D.Y. Li and D.L. Chen, Effect of Ti on the Wear Behavior of AlCoCrFeNi High-Entropy Alloy during Unidirectional and Bi-Directional Sliding Wear Processes, Wear, 2021, 476, 203650. https://doi.org/10.1016/j.wear.2021.203650

M. Löbel, T. Lindner, T. Mehner and T. Lampke, Microstructure and Wear Resistance of AlCoCrFeNiTi High-Entropy Alloy Coatings Produced by HVOF, Coatings, 2017, 7(9), p 144.

M. Chuang, M. Tsai, W. Wang, S. Lin and J. Yeh, Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy High-Entropy Alloys, Acta Mater., 2011, 59, p 6308-6317.

G.P. León, V.E. Lamberti, R.D. Seals, T.M. Abu-Lebdeh and S.A. Hamoush, Gas Atomization of Molten Metal: Part I. Numerical Modeling Conception, Am. J. Eng. Appl. Sci., 2016, 9(2), p 303-322. https://doi.org/10.3844/ajeassp.2016.303.322

J. Lehtonen, Y. Ge, N. Ciftci, O. Heczko, V. Uhlenwinkel and S.-P. Hannula, Phase Structures of Gas Atomized Equiatomic CrFeNiMn High Entropy Alloy Powder, J. Alloys Compd., 2020, 827, p 154142. https://doi.org/10.1016/j.jallcom.2020.154142

J. Liu, H. Liu, P. Chen and J. Hao, Microstructural Characterization and Corrosion Behaviour of AlCoCrFeNiTix High-Entropy Alloy Coatings Fabricated by Laser Cladding, Surf. Coatings Technol., 2019, 361, p 63-74. https://doi.org/10.1016/j.surfcoat.2019.01.044

A.S.M. Ang, C.C. Berndt, M.L. Sesso, A. Anupam, P. S, R.S. Kottada, and B.S. Murty, Plasma-Sprayed High Entropy Alloys: Microstructure and Properties of AlCoCrFeNi and MnCoCrFeNi, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2015, 46(2), 791-800.

F. Gärtner, T. Stoltenhoff, T. Schmidt and H. Kreye, The Cold Spray Process and Its Potential for Industrial Applications, J. Therm. Spray Technol., 2006, 15(2), p 223-232. https://doi.org/10.1361/105996306X108110

A. Anupam, S. Kumar, N.M. Chavan, B.S. Murty and R.S. Kottada, First Report on Cold-Sprayed AlCoCrFeNi High-Entropy Alloy and Its Isothermal Oxidation, J. Mater. Res., 2019, 34(5), p 796-806. https://doi.org/10.1557/jmr.2019.38

D.V. Hushchyk, A.I. Yurkova, V.V. Cherniavsky, I.I. Bilyk and S.O. Nakonechnyy, Nanostructured AlNiCoFeCrTi High-Entropy Coating Performed by Cold Spray, Appl. Nanosci., 2020, 10(12), p 4879-4890. https://doi.org/10.1007/s13204-020-01364-4

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu, K. Wen and R. Lupoi, Deposition of FeCoNiCrMn High Entropy Alloy (HEA) Coating via Cold Spraying, J. Mater. Sci. Technol., 2019, 35(6), p 1003-1007. https://doi.org/10.1016/j.jmst.2018.12.015

Y. Liang, B. Shi, X. Yang, J. Zhang and X. Meng, Microstructure and Nano-Mechanical Property of Cold Spray Co-Base Refractory Alloy Coating, Acta Metall. Sin. English Lett., 2011, 24(3), p 190-194.

C. Huang, W. Li, Y. Xie, M.-P. Planche, H. Liao and G. Montavon, Effect of Substrate Type on Deposition Behavior and Wear Performance of Ni-Coated Graphite/Al Composite Coatings Deposited by Cold Spraying, J. Mater. Sci. Technol., 2017, 33(4), p 338-346. https://doi.org/10.1016/j.jmst.2016.11.016

S. Yin, P. Cavaliere, B. Aldwell, R. Jenkins, H. Liao, W. Li and R. Lupoi, Cold Spray Additive Manufacturing and Repair: Fundamentals and Applications, Addit. Manuf., 2018, 21, p 628-650. https://doi.org/10.1016/j.addma.2018.04.017

L. Ajdelsztajn, B. Jodoin, G.E. Kim and J.M. Schoenung, Cold Spray Deposition of Nanocrystalline Aluminum Alloys, Metall. Mater. Trans. A, 2005, 36(11), p 3263-3263. https://doi.org/10.1007/s11661-005-0099-y

Q. Cao, G. Huang, L. Ma and L. Xing, Comparison of a Cold-sprayed and Plasma-sprayed Fe25Cr20Mo1Si Amorphous Alloy Coatings on 40Cr Substrates, Mater. Corros., 2020, 71(11), p 1872-1884. https://doi.org/10.1002/maco.202011558

J. Liang, K. Cheng and S. Chen, Effect of Heat Treatment on the Phase Evolution and Mechanical Properties of Atomized AlCoCrFeNi High-Entropy Alloy Powders, J. Alloys Compd., 2019, 803, p 484-490. https://doi.org/10.1016/j.jallcom.2019.06.301

S.-M. Chiu, T.-T. Lin, R.K. Sammy, N.G. Kipkirui, Y.-Q. Lin, J.-T. Liang and S.-H. Chen, Investigation of Phase Constitution and Stability of Gas-Atomized Al0.5CoCrFeNi2 High-Entropy Alloy Powders, Mater. Chem. Phys., 2022, 275, p 125194. https://doi.org/10.1016/j.matchemphys.2021.125194

S. Jiang, Z. Lin, H. Xu and Y. Sun, Studies on the Microstructure and Properties of AlxCoCrFeNiTi1-x High Entropy Alloys, J. Alloys Compd., 2018, 741, p 826-833. https://doi.org/10.1016/j.jallcom.2018.01.247

E. Garcia, H. Lee and S. Sampath, Phase and Microstructure Evolution in Plasma Sprayed Yb2Si2O7 Coatings, J. Eur. Ceram. Soc., 2019, 39(4), p 1477-1486. https://doi.org/10.1016/j.jeurceramsoc.2018.11.018

J. Luo, N. Shi, Y.-Z. Xing, C. Jiang and Y. Chen, Effect of Arc Power on the Wear and High-Temperature Oxidation Resistances of Plasma-Sprayed Fe-Based Amorphous Coatings, High Temp. Mater. Process., 2019, 2019(38), p 639-646. https://doi.org/10.1515/htmp-2019-0003

C. Lee and J. Kim, Microstructure of Kinetic Spray Coatings: A Review, J. Therm. Spray Technol., 2015, 24(4), p 592-610. https://doi.org/10.1007/s11666-015-0223-5

H.-T. Wang, C.-J. Li, G.-J. Yang, C.-X. Li, Q. Zhang and W.-Y. Li, Microstructural Characterization of Cold-Sprayed Nanostructured FeAl Intermetallic Compound Coating and Its Ball-Milled Feedstock Powders, J. Therm. Spray Technol., 2007, 16(5-6), p 669-676. https://doi.org/10.1007/s11666-007-9089-5

A. Chaudhuri, Y. Raghupathy, D. Srinivasan, S. Suwas and C. Srivastava, Microstructural Evolution of Cold-Sprayed Inconel 625 Superalloy Coatings on Low Alloy Steel Substrate, Acta Mater., 2017, 129, p 11-25. https://doi.org/10.1016/j.actamat.2017.02.070

K. Kim, S. Kuroda, M. Watanabe, R. Huang, H. Fukanuma and H. Katanoda, Comparison of Oxidation and Microstructure of Warm-Sprayed and Cold-Sprayed Titanium Coatings, J. Therm. Spray Technol., 2012, 21(June), p 550-560. https://doi.org/10.1007/s11666-011-9703-4

H.-T. Wang, C.-J. Li, G.-J. Yang and C.-X. Li, Effect of Heat Treatment on the Microstructure and Property of Cold-Sprayed Nanostructured FeAl/Al2O3 Intermetallic Composite Coating, Vacuum, 2008, 83(1), p 146-152. https://doi.org/10.1016/j.vacuum.2008.03.094

L. Shaw, H. Luo, J. Villegas and D. Miracle, Thermal Stability of Nanostructured Al93Fe3Cr2Ti2 Alloys Prepared via Mechanical Alloying, Acta Mater., 2003, 51(9), p 2647-2663.

T. Hussain, D.G. McCartney and P.H. Shipway, Bonding between Aluminium and Copper in Cold Spraying: Story of Asymmetry, Mater. Sci. Technol., 2012, 28(12), p 1371-1378. https://doi.org/10.1179/1743284712Y.0000000051

Y. Li, X. Wang, S. Yin and S. Xu, Influence of Particle Initial Temperature on High Velocity Impact Process in Cold Spraying, Procedia Environ. Sci., 2011, 2012(12(Icese)), p 298-304. https://doi.org/10.1016/j.proenv.2012.01.281

M.R. Rokni, S.R. Nutt, C.A. Widener, V.K. Champagne and R.H. Hrabe, Review of Relationship Between Particle Deformation, Coating Microstructure, and Properties in High-Pressure Cold Spray, J. Therm. Spray Technol., 2017, 26(6), p 1308-1355. https://doi.org/10.1007/s11666-017-0575-0

R. Drehmann, T. Grund, T. Lampke, B. Wielage, C. Wüstefeld, M. Motylenko and D. Rafaja, Essential Factors Influencing the Bonding Strength of Cold-Sprayed Aluminum Coatings on Ceramic Substrates, J. Therm. Spray Technol., 2018, 27(3), p 446-455. https://doi.org/10.1007/s11666-018-0688-0

Acknowledgment

Authors acknowledge the support from the Ministry of Science and Technology of Taiwan under Project No. 107-2218-E-011-017 and the support by the Research Center for Intelligent Medical Devices, Ming Chi University of Technology. This work was financially supported by the “High Entropy Materials Center” from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) and from Project MOST 109-2634-F-007-024 by the Ministry of Science and Technology (MOST) in Taiwan. Thanks for Plus Metal Tech., Co. supporting in conducting plasma and cold spraying processes.

Author information

Authors and Affiliations

Contributions

Rotich Sammy Kiplangat was involved in writing—original draft, investigation. Tzu-Tang Lin performed writing—review & editing and investigation. Ngetich Gilbert Kipkirui contributed to investigation and data curation. Shih-Hsun Chen did supervision, methodology and resources.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Kiplangat, R.S., Lin, TT., Kipkirui, N.G. et al. Microstructure and Mechanical Properties of the Plasma-Sprayed and Cold-Sprayed Al0.5CoCrFeNi2Ti0.5 High-Entropy Alloy Coatings. J Therm Spray Tech 31, 1207–1221 (2022). https://doi.org/10.1007/s11666-022-01356-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01356-6