Abstract

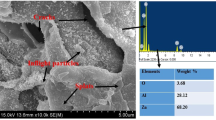

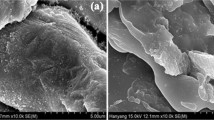

This study investigated the corrosion performance of wire arc deposited zinc-aluminum pseudo alloy coating (Zn-Al pseudo alloy) with higher aluminum content and Zn-15Al alloy coating in the aggressive chloride environment. The performance of both coatings was assessed by employing morphological analysis, chemical composition and material characterization tests, and electrochemical studies. Micrographs of the as-deposited coatings revealed a denser and compact microstructure in the pseudo alloy coating compared to Zn-15Al coating. The electrochemical test results demonstrated that the pseudo alloy coating exhibited a four times lower corrosion rate and four times higher corrosion resistance compared to the Zn-15Al coating. Although, the formation of simonkolleite is noticed in the corrosion products of both the coatings, a more thin and compact corrosion product layer is observed in the pseudo alloy coating. The superior performance of Zn-Al pseudo alloy coating can be attributed to the presence of higher aluminum content and the existence of zinc-rich and aluminum-rich areas in the coating microstructure, where zinc offers sacrificial protection at the aluminum-rich region boundaries, in addition to the formation of stable corrosion products of zinc at zinc-rich areas, passivation of aluminum at the aluminum-rich areas, reduced the overall rate of corrosion in such coatings.

Similar content being viewed by others

References

K.A. Chandler, Marine and Offshore Corrosion, Elsevier, London, 1985.

J.P. Ault, The Use of Coatings for Corrosion Control on Offshore Oil Structures, J. Prot. Coat. Linings, 2006, 23(4), p 42–46.

A. López-Ortega, R. Bayón and J. Arana, Evaluation of Protective Coatings for Offshore Applications. Corrosion and Tribocorrosion Behavior in Synthetic Seawater, Surf. Coat. Technol., 2018, 349, p 1083–1097.

M. Iannuzzi, A. Barnoush and R. Johnsen, Materials and Corrosion Trends in Offshore and Subsea Oil and Gas Production, NPJ Mater. Degrad., 2017, 1(1), p 1–11.

K.Y. Ann and H.-W. Song, Chloride Threshold Level for Corrosion of Steel in Concrete, Corros. Sci., 2007, 49(11), p 4113–4133.

H.U. Sajid and R. Kiran, Influence of Corrosion and Surface Roughness on Wettability of ASTM A36 Steels, J. Constr. Steel Res., 2018, 144, p 310–326.

H.U. Sajid, R. Kiran, X. Qi, D.S. Bajwa and D. Battocchi, Employing Corn Derived Products to Reduce the Corrosivity of Pavement Deicing Materials, Constr. Build. Mater., 2020, 263, p 120662.

F. Deng, Y. Huang, F. Azarmi and Y. Wang, Pitted Corrosion Detection of Thermal Sprayed Metallic Coatings Using Fiber Bragg Grating Sensors, Coatings, 2017, 7(3), p 35.

P.A. Sørensen, S. Kiil, K. Dam-Johansen and C.E. Weinell, Anticorrosive Coatings: A Review, J. Coat. Technol. Res., 2009, 6(2), p 135–176.

Y.-T. Li and B.-R. Hou, Anticorrosion Mechanism of Thermal Spraying Coatings of Zinc and Aluminum and of Alloys Made of the Same in Marine Environment: A Review, Mater. Prot.-Wuhan-, 2005, 38(9), p 30.

A. Farooq, M. Hamza, Q. Ahmed and K.M. Deen, Evaluating the Performance of Zinc and Aluminum Sacrificial Anodes in Artificial Seawater, Electrochim. Acta, 2019, 314, p 135–141.

S. Schuerz, M. Fleischanderl, G. Luckeneder, K. Preis, T. Haunschmied, G. Mori and A. Kneissl, Corrosion Behaviour of Zn–Al–Mg Coated Steel Sheet in Sodium Chloride-Containing Environment, Corros. Sci., 2009, 51(10), p 2355–2363.

E.A. Esfahani, H. Salimijazi, M.A. Golozar, J. Mostaghimi and L. Pershin, Study of Corrosion Behavior of Arc Sprayed Aluminum Coating on Mild Steel, J. Therm. Spray Technol., 2012, 21(6), p 1195–1202.

T.-Y. Yung, T.-C. Chen, K.-C. Tsai, W.-F. Lu, J.-Y. Huang and T.-Y. Liu, Thermal Spray Coatings of Al, ZnAl and Inconel 625 Alloys on SS304L for Anti-Saline Corrosion, Coatings, 2019, 9(1), p 32.

P. Fauchais and A. Vardelle, Thermal Sprayed Coatings used Against Corrosion and Corrosive Wear, Adv. Plasma Spray Appl., 2012, 10, p 34448.

R.M.H.P. Rodriguez, R.S.C. Paredes, S.H. Wido and A. Calixto, Comparison of Aluminum Coatings Deposited by Flame Spray and by Electric Arc Spray, Surf. Coat. Technol., 2007, 202(1), p 172–179.

E. Dalledone, M. Barbosa and S. Wolynec, Zinc-55% Aluminum-16% Silicon Coating Compared with Zinc Coating, Mater. Perform., 1995, 34(7), p 1203.

A. Marder, The Metallurgy of Zinc-Coated Steel, Prog. Mater Sci., 2000, 45(3), p 191–271.

Z. Panossian, L. Mariaca, M. Morcillo, S. Flores, J. Rocha, J. Pena, F. Herrera, F. Corvo, M. Sanchez and O. Rincon, Steel Cathodic Protection Afforded by Zinc, Aluminium and Zinc/Aluminium Alloy Coatings in the Atmosphere, Surf. Coat. Technol., 2005, 190(2–3), p 244–248.

A. Gulec, O. Cevher, A. Turk, F. Ustel and F. Yilmaz, Accelerated Corrosion Behaviors of Zn, Al and Zn/15Al Coatings on a Steel Surface, Materiali in tehnologije, 2011, 45(5), p 477–482.

Y. Li, Corrosion Behaviour of Hot Dip Zinc and Zinc-Aluminium Coatings on Steel in Seawater, Bull. Mater. Sci., 2001, 24(4), p 355–360.

G. Kong and R. White, Toward Cleaner Production of Hot Dip Galvanizing Industry in China, J. Clean. Prod., 2010, 18(10–11), p 1092–1099.

S. Egtvedt, "Thermally Sprayed Aluminum (TSA) with Cathodic Protection as Corrosion Protection for Steel in Natural Seawater: Characterization of Properties on TSA and Calcareous Deposit," Institutt for materialteknologi, 2011

D. Mari, L. Miguel and C.E. Nebel, Comprehensive Hard Materials, Newnes, New York, 2014.

J.R. Davis, Handbook of Thermal Spray Technology, ASM international, New York, 2004.

M.H. Abd Malek, N.H. Saad, S.K. Abas, N.M. Shah, Thermal arc spray overview, in IOP Conference Series: Materials Science and Engineering, 2013, IOP Publishing, pp. 012028

R. Bolot, R. Bonnet, G. Jandin and C. Coddet, Application of CAD to CFD for the Wire Arc Spray Process, Thermal Spray, 2001, 2, p 889–894.

B. Syrek-Gerstenkorn, S. Paul and A.J. Davenport, Sacrificial Thermally Sprayed Aluminium Coatings for Marine Environments: A Review, Coatings, 2020, 10(3), p 267.

S. Kuroda, J. Kawakita and M. Takemoto, An 18-year Exposure Test of Thermal-Sprayed Zn, Al, and Zn-Al Coatings in Marine Environment, Corrosion, 2006, 62(7), p 635–647.

A. Güleç, Ö. Cevher, A. Türk, F. Ustel and F. Yılmaz, Accelerated Corrosion Behaviors of Zn, Al and Zn/15Al Coatings on a Steel Surface, Science, 2011, 2, p 1–1008.

L. Qiao, Y. Wu, J. Duan, W. Gao and S. Hong, Corrosion Behavior of Arc-Sprayed Pore-Sealed Zn and Al Coatings in Seawater Containing Sulfate-Reducing Bacteria (SRB), J. Therm. Spray Technol., 2021, 30(6), p 1557–1565.

S. Hong, Y. Wu, W. Gao, J. Zhang and Y. Qin, Corrosion Behavior of Arc-Sprayed Zn-Al Coating in the Presence of Sulfate-Reducing Bacteria in Seawater, J. Mater. Eng. Perform., 2015, 24(11), p 4449–4455.

H. Katayama and S. Kuroda, Long-Term Atmospheric Corrosion Properties of Thermally Sprayed Zn, Al and Zn–Al Coatings Exposed in a Coastal Area, Corros. Sci., 2013, 76, p 35–41.

A.Q. Liu, K. Xiao, C.F. Dong and X.G. Li, Corrosion Behaviour of Zn-Al Pseudo-Alloy Coating on Carbon Steel in Chloride Environments, Advanced Materials Research, Springer, Berlin, 2012, p 45–48

H.-S. Lee, J.K. Singh, M.A. Ismail, C. Bhattacharya, A.H. Seikh, N. Alharthi and R.R. Hussain, Corrosion Mechanism and Kinetics of Al-Zn Coating Deposited by arc Thermal Spraying Process in Saline Solution at Prolong Exposure Periods, Sci. Rep., 2019, 9(1), p 1–17.

H. Hu, P. Zhang, D. Wei and F. Su, Microstructure and Corrosion Behavior of Arc Sprayed Zn-xAl (x= 15, 30, 50) Alloy Coatings in NaCl Solution, Mater. Res. Express, 2019, 6(10), p 1065f1067.

S. Djerourou, H. Lahmar, N. Bouhellal, Y. Mebdoua, Study of Twin Wire Arc Sprayed Zinc/Aluminum Coating on Low Carbon Steel Substrate: Application to Corrosion Protection, Advanced materials research, 2013, Trans Tech Publ, pp. 271–276

A. Darabi and F. Azarmi, Investigation on Relationship Between Microstructural Characteristics and Mechanical Properties of Wire-Arc-Sprayed Zn-Al Coating, J. Therm. Spray Technol., 2020, 29(1–2), p 297–307.

H.-S. Lee, J.K. Singh and J.H. Park, Pore Blocking Characteristics of Corrosion Products Formed on Aluminum Coating Produced by Arc Thermal Metal Spray Process in 35 wt.% NaCl Solution, Constr. Build. Mater., 2016, 113, p 905–916.

Q. Jiang, Q. Miao, W.-P. Liang, F. Ying, F. Tong, Y. Xu, B.-L. Ren, Z.-J. Yao and P.-Z. Zhang, Corrosion Behavior of Arc Sprayed Al–Zn–Si–RE Coatings on Mild Steel in 3.5 wt% NaCl Solution, Electrochimica Acta, 2014, 115, p 644–656.

A. B117, Standard Practice for Operating Salt Spray (Fog) Apparatus (ASTM International, 2011)

K. Geels, D.B. Fowler, W.-U. Kopp and M.R. Ckert, Metallographic and Materialographic Specimen Preparation, Light Microscopy, Image Analysis, and Hardness Testing, ASTM international, West Conshohocken, 2007.

Y. Meng, L. Liu, D. Zhang, C. Dong, Y. Yan, A.A. Volinsky and L.-N. Wang, Initial Formation of Corrosion Products on Pure Zinc in Saline Solution, Bioactive Mater., 2019, 4, p 87–96.

A. Güleç, Ö. Cevher, F. Üstel, A. Türk, A. Akıncı, F. Yılmaz, Performance Comparison of Thermal-Sprayed Coatings for Ductile Iron Pipe (2011).

S. Tailor, A. Modi and S. Modi, Synthesis, Microstructural, Corrosion and Antimicrobial Properties of Zn and Zn–Al Coatings, Surf. Eng., 2019, 35(8), p 736–742.

S.F. Bonabi, F. Ashrafizadeh, A. Sanati and S.M. Nahvi, Structure and Corrosion Behavior of Arc-Sprayed Zn-Al Coatings on Ductile Iron Substrate, J. Therm. Spray Technol., 2018, 27(3), p 524–537.

A.R. Moreira, Z. Panossian, P.L. Camargo, M.F. Moreira, I.C.D. Silva and J.E.R. de Carvalho, Zn/55Al Coating Microstructure and Corrosion Mechanism, Corros. Sci., 2006, 48(3), p 564–576.

H. Dingyong, G. Dandan and J. Jianmin, Corrosion Behavior of Arc Sprayed Aluminum Coating on Magnesium Alloy in Chlorine Ion, Weld. Join., 2007, 3, p 1229.

C. Vargel, Corrosion of Aluminium, Elsevier, New York, 2020.

V.S. Bagotsky, Fundamentals of Electrochemistry, Wiley, New York, 2005.

P. Marcus, Corrosion Mechanisms in Theory and Practice, CRC Press, London, 2011.

H. Marchebois, S. Joiret, C. Savall, J. Bernard and S. Touzain, Characterization of Zinc-Rich Powder Coatings by EIS and Raman Spectroscopy, Surf. Coat. Technol., 2002, 157(2–3), p 151–161.

T. Nguyen, J. Hubbard and J. Pommersheim, Unified Model for the Degradation of Organic Coatings on Steel in a Neutral Electrolyte, JCT J. Coat. Technol., 1996, 68(855), p 45–56.

A. Goyal, H.S. Pouya, E. Ganjian and P. Claisse, A Review of Corrosion and Protection of Steel in Concrete, Arab. J. Sci. Eng., 2018, 43(10), p 5035–5055.

Y. Liu, B.-S. Xu, Z.-X. Zhu, Z.-X. Li and J. Ma, New Pattern Zn-Al-Mg-RE Coating Technics for Steel Structure Sustainable Design, J. Cent. South Univ. Technol., 2005, 12(2), p 211–214.

R. Landolfo, L. Cascini and F. Portioli, Modeling of Metal Structure Corrosion Damage: A State of the Art Report, Sustainability, 2010, 2(7), p 2163–2175.

G. Astm, Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements, Ann. Book ASTM Stand., 2009, 3, p 237–239.

A. Momber, P. Plagemann and V. Stenzel, Performance and Integrity of Protective Coating Systems for Offshore Wind Power Structures After Three Years Under Offshore Site Conditions, Renew. Energy, 2015, 74, p 606–617.

B. Hinderliter, S. Croll, D. Tallman, Q. Su and G. Bierwagen, Interpretation of EIS Data from Accelerated Exposure of Coated Metals Based on Modeling of Coating Physical Properties, Electrochim. Acta, 2006, 51(21), p 4505–4515.

A. López-Ortega, J. Arana and R. Bayón, Tribocorrosion of Passive Materials: A Review on Test Procedures and Standards, Int. J. Corros., 2018, 17, p 10029.

F. Mansfeld and C. Tsai, Determination of Coating Deterioration with EIS: I. Basic Relationships, Corrosion, 1991, 47(12), p 958–963.

Acknowledgments

This work was supported by the National Science Foundation under Grant No. CMMI-1750316. The findings and opinions expressed in this article are those of the authors only and do not necessarily reflect the views of the sponsors. In addition, the suppliers and point of contacts from Thermal Spray Depot (Washington, PA, USA) are gratefully acknowledged for providing materials and support.

Author information

Authors and Affiliations

Contributions

Ratna: Data curation, Methodology, Formal analysis, Investigation, Writing - original draft, Writing - review & editing. Ying Huang: Project administration, Funding acquisition, Supervision, Writing - review & editing. Xiaoning Qi: Supervision, Writing - review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yasoda, R.D., Huang, Y. & Qi, X. Corrosion Performance of Wire Arc Deposited Zinc Aluminum Pseudo Alloy and Zinc 15 Aluminum Alloy Coatings on Steel in Chloride Environment. J Therm Spray Tech 31, 1918–1933 (2022). https://doi.org/10.1007/s11666-022-01329-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01329-9