Abstract

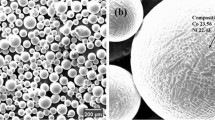

A novel FeB-10 wt.% Mo-12 wt.% Al0.25FeNiCoCr (denoted as FeB-10 Mo-12 HEA) cermet and coating were prepared by spark plasma sintering (SPS) and an activated combustion high-velocity air fuel (AC-HVAF) spraying process, respectively. The microstructure, phase compositions, density, microhardness, thermal shock and corrosion resistance of the cermet and coating to molten zinc were characterized in detail. The results show that the phase composition of the coating was the same as that of the cermet, which was composed of an (Fe, Al, Ni, Co, Cr)B solid solution, an (Fe, Al, Ni, Co, Cr)2B solid solution and a Mo phase. The brittleness of FeB and Fe2B was reduced by the Al, Fe, Ni, Co and Cr elements of the high-entropy alloy that was dissolved into them. The addition of Mo, which did not undergo a eutectic reaction with Zn at 450 °C, and the corrosion products (δ phase) increased the corrosion resistance of the novel cermet. Compared with the cermet that was prepared by SPS, the coating that was prepared by AC-HVAF had a lower density, lower microhardness value and worse corrosion resistance to molten zinc because of the layered structure of the coating, in which cracks could form and propagate easily under the action of thermal stress.

Similar content being viewed by others

References

C.D. Rovere, R. Silva, C. Moretti and S.E. Kuri, Corrosion Failure Analysis of Galvanized Steel Pipes in a Water Irrigation System, Eng. Fail. Anal., 2013, 33, p 381–386.

A.R. Marder, The Metallurgy of Zinc-Coated Steel, Prog. Mater. Sci., 2000, 45, p 191–271.

A. Colombo, L. Oldani and S.P. Trasatti, Corrosion Failure Analysis of Galvanized Steel Pipes in a Closed Water Cooling System, Eng. Fail. Anal., 2017, 84, p 46–58.

G. Zhang, Y. Wang, S. Zhang and C. Liu, Corrosion Failure Analysis of Hot-Dip Galvanized Steel in a Room Environment, J. Fail. Anal. Preven., 2015, 15(6), p 1–5.

J. Hu, F. Yin, M. Zhao and X. Ouyang, Experimental Investigation and Thermodynamic Calculation of the Co-Sn-Zn Ternary System, J. Alloy Compd., 2018, 747, p 815–825.

M. Zhao, F. Yin, Z. Li, Z. Long and X. Wang, 450 °C Isothermal Section of the Zn-Fe-Co-Si Quaternary System at the Zinc-Rich Corner, Int. J. Mater. Res., 2013, 1(104), p 35–45.

S. Shibli, B. Meena and R. Remya, A Review on Recent Approaches in the Field of Hot Dip Zinc Galvanizing Process, Surf. Coat. Technol., 2015, 262, p 210–215.

X. Ren, X. Mei, J. She and J. Ma, Materials Resistance to Molten Zinc Corrosion on Surface of Sink Roll, J. Iron Steel Res. Int., 2007, 14(5), p 130–136.

L. Wang, Y. Zhou, G. Chen, P. Xu and S. Rao, Analysis on Dominant Influencing Factors of On-Line Life Cycle in Sink Roll System and Effective Improved Methods, Eng. Fail. Anal., 2015, 58, p 8–18.

S. Ma, J. Xing, H. Fu, Y. He, Y. Bai, Y. Li and Y. Bai, Interface Characteristics and Corrosion Behaviour of Oriented Bulk Fe2B Alloy in Molten Zinc, Corros. Sci., 2014, 78, p 71–80.

M. Wang, R. Gao, H. Gao, Y. Zhou, Y. Fan, Y. Zhao, J. Ju, Y. Liu, M. Kang and J. Wang, Improved Corrosion Resistance of Ni-Modified Fe-Cr-B Steel in Molten Zinc via Phase Transformation and Microstructure Control, Surf. Coat. Technol., 2019, 374, p 975–986.

W. Wang, J. Lin, Y. Wang and G. Chen, The Corrosion of Intermetallic Alloys in Molten Zinc, J. Alloy Compd., 2007, 428(1–2), p 237–243.

J. Zhang, C. Deng, J. Song, C. Deng, M. Liu and K. Zhou, MoB-CoCr as Alternatives to WC-12Co for Stainless Steel Protective Coating and its Corrosion Behavior in Molten Zinc, Surf. Coat. Technol., 2013, 235, p 811–818.

B. Seong, S. Hwang, M. Kim and K. Kim, Reaction of WC-Co Coating with Molten Zinc in a Zinc Pot of a Continuous Galvanizing Line, Surf. Coat. Technol., 2001, 138(1), p 101–110.

Y. Dong, D. Yan, J. He, J. Zhang and X. Li, Degradation Behaviour of ZrO2-Ni/Al Gradient Coatings in Molten Zn, Surf. Coat. Technol., 2006, 201(6), p 2455–2459.

D.N. Tsipas, G.K. Triantafyllidis, J.K. Kiplagat and P. Psillaki, Degradation Behaviour of Boronized Carbon and High Alloy Steels in Molten Aluminium and Zinc, Mater. Lett., 1998, 37(3), p 128–131.

S. Ma, J. Xing, H. Fu, D. Yi, J. Zhang, Y. Li, Z. Zhang, B. Zhu and S. Ma, Interfacial Morphology and Corrosion Resistance of Fe-B Cast Steel Containing Chromium and Nickel in Molten Zinc, Corros. Sci., 2011, 53(9), p 2826–2834.

Y. Wang, J. Xing, S. Ma, G. Liu, Y. He, D. Yang and Y. Bai, Effect of Fe2B Orientation on Erosion-Corrosion Behavior of Fe-3.5 wt.% B Steel in Flowing Zinc, Corros. Sci., 2015, 98, p 240–248.

Y. Wang, J. Xing, S. Ma, B. Zheng, G. Liu, D. Yang and Y. Bai, Interface Characterization and Erosion-Corrosion Behavior of Directional Fe-3.5 wt.% B Steel in Flowing Molten Zinc at Various Temperatures, Corros. Sci., 2016, 104, p 260–268.

X. Liu, M. Wang, F. Yin, X. Ouyang and Z. Li, Effects of Tungsten Addition on the Microstructure and Corrosion Resistance of Fe-3.5B Alloy in Liquid Zinc, Materials, 2017, 10(4), p 99–413.

X. Ouyang, G. Chen, F. Yin, Y. Liu and M. Zhao, Effect of Molybdenum on the Microstructures of As-Cast Fe-B Alloys and Their Corrosion Resistance in Molten Zinc, Corrosion, 2017, 73(8), p 942–952.

P. Ye, F. Yin, Y. Liu, X. Ouyang and X. Xie, Corrosion Resistance of Liquid Zinc of FeB/Co Cermet Coating Deposited by AC-HVAF, T. Nonferr. Metal. Soc., 2018, 28(4), p 782–791. ((in chinese))

X. Xie, F. Yin, X. Wang, X. Ouyang, M. Li and J. Hu, Corrosion Resistance to Molten Zinc of a Novel Cermet Coating Deposited by Activated Combustion High-Velocity Air Fuel (AC-HVAF), J. Therm. Spray Technol., 2019, 28, p 1252–1262.

Y. Garip, N. Ergin and O. Ozdemir, Resistance Sintering of CoCrFeNiAlx (x = 0.7, 0.85, 1) High Entropy Alloys: Microstructural Characterization, Oxidation and Corrosion Properties, J. Alloy Compd., 2021, 877, p 160180.

V. Nečina and W. Pabst, Influence of the Heating Rate on Grain Size of Alumina Ceramics Prepared via Spark Plasma Sintering (SPS), J. Eur. Ceram. Soc., 2020, 40, p 3656–3662.

K. Feng, Y. Yang, M. Hong, J. Wu and S. Lan, Intensified Sintering of Iron Powders Under the Action of an Electric Field: Effect of Technologic Parameter on Sintering Densification, J. Mater. Process. Technol., 2008, 208, p 264–269.

Y. Zhang and J. Zhang, Rapid Reactive Synthesis and Sintering of Textured Ca3Co4O9 Ceramics by Spark Plasma Sintering, J. Mater. Process. Technol., 2008, 208, p 70–74.

H. Feng, Y. Zhou, D. Jia and Q. Meng, Rapid Synthesis of Ti Alloy with B Addition by Spark Plasma Sintering, Mater. Sci. Eng. A, 2005, 390, p 344–349.

J. Lu, Y. Chen, H. Zhang, N. Ni, L. Li, L. He, R. Mu, X. Zhao and F. Guo, Y/Hf-Doped AlCoCrFeNi High-Entropy Alloy with Ultra Oxidation and Spallation Resistance, Corros. Sci., 2020, 166, p 108426.

Y. Yang, B. Yin, Y. Shang, X. Wang and J. Chen, Preparation and Characterization of Novel TiB2-12 (Fe-Co-Cr-Ni) Cermets and Their Corrosion Resistance in Molten Aluminum, Corros. Sci., 2021, 190(1), p 109643.

X. Zhang, W. Chen, H. Luo, S. Li, T. Zhou and L. Shi, Corrosion Resistance and Interfacial Morphologies of Novel Fe-Cr-Mo-B Cast Steels in Molten Aluminum, Corros. Sci., 2017, 125, p 20–28.

H. Ikeda, and K. Yanagimoto, Surface Coating Material for Molten Zinc Bath Member, Production Method Thereof, and Molten Zinc Bath Member, U.S. Patent 8927111 (2015)

N.O. Engin and A.C. Tas, Manufacture of Macroporous Calcium Hydroxyapatite Bioceramics, J. Eur. Ceram. Soc., 1999, 19(13–14), p 2569–2572.

X. Xie, B. Yin, F. Yin and X. Ouyang, Corrosion Behavior of FeB-30 wt.% Al0.25FeNiCoCr Cermet Coating in Liquid Zinc, Coatings, 2021, 11(6), p 622.

M. Wang, J. Xue, R. Gao, H. Gao, Y. Zhou, Y. Zhao, Y. Liu, M. Kang and J. Wang, Interface Morphology and Corrosion Behavior of Bulk Fe2B in Liquid Al, Mater. Charact., 2019, 152, p 1–11.

M. Kulka, N. Makuch and A. Piasecki, Nanomechanical Characterization and Fracture Toughness of FeB and Fe2B Iron Borides Produced by Gas Boriding of Armco Iron, Surf. Coat. Technol., 2017, 325, p 515–532.

O. Allaoui, N. Bouaouadja and G. Saindernan, Characterization of Boronized Layers on a XC38 Steel, Surf. Coat. Technol., 2006, 201, p 3475–3482.

Y. Song, X. Zhuan, T. Wang and X. Chen, Thermal Stress in Fabrication of Thermal Barrier Coatings, J. Therm. Stress., 2014, 37(12), p 1390–1415.

Y. Song, Z. Lv, Y. Liu, X. Zhuan and T. Wang, Effects of Coating Spray Speed and Convective Heat Transfer on Transient Thermal Stress in Thermal Barrier Coating System during the Cooling Process of Fabrication, Appl. Surf. Sci., 2015, 324, p 627–633.

T. Clyne and S. Gill, Residual Stresses in Thermal Spray Coatings and Their Effect on Interfacial Adhesion: A Review of Recent Work, J. Therm. Spray Technol., 1996, 5(4), p 401–418.

Z. Peng, X. Wang, F. Yin, X. Ouyang and J. Hu, Phase Equilibria of Co-Mo-Zn Ternary System, T. Nonferr. Metal. Soc., 2020, 30(2), p 417–427.

F. Yin, X. Ruan, M. Zhao, Y. Liu and Z. Li, The 600 °C and 450 °C Isothermal Sections of the Zn-Fe-B System, J. Alloy Compd., 2013, 565(15), p 79–84.

Acknowledgments

This work has been funded by the National Science Foundation of the China (Nos. 11904307, 52001268 and 51771160), the Scientific Research Fund of Hunan Provincial Educational Department (Nos. 18C0111 and 20C1797), the Natural Science Foundation of Hunan Province (Grant Nos. 2019JJ50576 and 2021JJ40539), and the Hunan Postgraduate Research and Innovation Project (No. CX20190478).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Xie, X., Yin, B., Yang, Y. et al. Corrosion Resistance to Molten Zinc of a Novel FeB-10 Mo-12 Al0.25FeNiCoCr Cermet and Coating. J Therm Spray Tech 31, 1423–1438 (2022). https://doi.org/10.1007/s11666-021-01283-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01283-y