Abstract

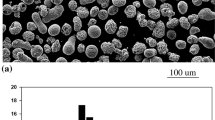

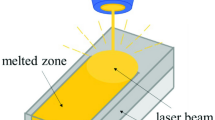

This work is focused on furnace and laser post-treatment and characterization of WC-Ti cermet coatings obtained by cold gas spray technique. The main purposes of this study are (i) to find a suitable alternative to cobalt as metallic binder, since it has been listed as a critical material and (ii) to investigate the effects of different post-deposition heat treatments, carried out to trigger a self-propagating high-temperature synthesis reaction able to promote a partial and controlled decarburization of WC and the consequential in-situ nucleation of TiC micro/nano-precipitates. A standard furnace heat-treatment at 550 °C and different laser treatments were performed with the aim of increasing the overall coating microhardness.

The effects of the furnace and laser treatments on the WC-Ti coatings were evaluated in terms of microscopic, compositional and phase analyses and through preliminary block-on-ring sliding wear tests. The microstructure exhibited a good distribution of carbides, with an average size ranging from submicrometric to 5μm, and the XRD analysis revealed the formation of TiC in the laser-treated coatings. In the sliding wear tests, the laser-treated materials showed a significative reduction in the wear rate, with a weight loss up to 75% lower than both the furnace-treated and the as-sprayed coatings.

Similar content being viewed by others

References

J.A. Picas, Y. Xiong, M. Punset, L. Ajdelsztajn, A. Forn and J.M. Schoenung, Microstructure and Wear Resistance of WC–Co by Three Consolidation Processing Techniques, Int. J. Refract. Met. Hard Mater., 2009, 27(2), p 344–349. https://doi.org/10.1016/j.ijrmhm.2008.07.002

L. Baiamonte, G. Pulci, E. Hlede, F. Marra and C. Bartuli, Thermal Spray Coatings for Corrosion and Wear Protection of Naval Diesel Engines Components, Metall. Ital., 2014, 106(6), p 9–13.

A. Mateen, G.C. Saha, T.I. Khan and F.A. Khalid, Tribological Behaviour of HVOF Sprayed Near-Nanostructured and Microstructured WC-17wt.%Co Coatings, Surf. Coatings Technol., 2011, 206(6), p 1077–1084.

A.H. Tkaczyk, A. Bartl, A. Amato, V. Lapkovskis and M. Petranikova, Sustainability Evaluation of Essential Critical Raw Materials: Cobalt, Niobium, Tungsten and Rare Earth Elements, J. Phys. D. Appl. Phys., 2018, 51(20), p 203001. https://doi.org/10.1088/1361-6463/aaba99

S. van den Brink, R. Kleijn, B. Sprecher and A. Tukker, Identifying Supply Risks by Mapping the Cobalt Supply Chain, Resour. Conserv. Recycl., 2020, 156, p 104743.

M. Suh, C.M. Thompson, G.P. Brorby, L. Mittal and D.M. Proctor, Inhalation Cancer Risk Assessment of Cobalt Metal, Regul. Toxicol. Pharmacol., 2016, 79, p 74–82.

R.S. Lima, J. Karthikeyan, C.M. Kay, J. Lindemann and C.C. Berndt, Microstructural Characteristics of Cold-Sprayed Nanostructured WC-Co Coatings, Thin Solid Films, 2002, 416(1–2), p 129–135.

S. Dosta, G. Bolelli, A. Candeli, L. Lusvarghi, I.G. Cano and J.M. Guilemany, Plastic Deformation Phenomena during Cold Spray Impact of WC-Co Particles onto Metal Substrates, Acta Mater., 2017, 124, p 173–181. https://doi.org/10.1016/j.actamat.2016.11.010

C. Verdon, A. Karimi and J.L. Martin, A Study of High Velocity Oxy-Fuel Thermally Sprayed Tungsten Carbide Based Coatings. Part 1: Microstructures, Mater. Sci. Eng. A, 1998, 246(1–2), p 11–24.

A. Moridi, S.M. Hassani-Gangaraj, M. Guagliano and M. Dao, Cold Spray Coating: Review of Material Systems and Future Perspectives, Surf. Eng., 2014, 30(6), p 369–395.

A. Papyrin, in The Cold Spray Materials Deposition Process: Fundamentals and Applications, ed. by V.K. Champagne. The development of the cold spray process (Elsevier, 2007), pp. 11–42. https://doi.org/10.1533/9781845693787

R. Huang and H. Fukanuma, 6 - Future Trends in Cold Spray Techniques, N.B.T.-F.D. of T.S.C. Espallargas, Ed., Woodhead Publishing, 2015, p 143–162, https://doi.org/10.1016/B978-0-85709-769-9.00006-3.

A. Nastic, D. MacDonald and B. Jodoin, The Influence of Feedstock Powder, Cold Spray in the Realm of Additive Manufacturing Materials Forming. S. Pathak, G. Saha Ed., Machining and Tribology. Springer, Cham, 2020. https://doi.org/10.1007/978-3-030-42756-6_3

S. Yin, E.J. Ekoi, T.L. Lupton, D.P. Dowling and R. Lupoi, Cold Spraying of WC-Co-Ni Coatings Using Porous WC-17Co Powders: Formation Mechanism, Microstructure Characterization and Tribological Performance, Mater. Des., 2017, 126, p 305–313.

P. Matteazzi, A. Colella, V. Leshchynsky, K. Sakaki, H. Fukanuma and R.G. Maev, Cold Spray Powders and Equipment, Cold Gas Dynamic Spray. R.G. Maev, V. Leshchynsky Ed., Taylor & Francis Group, Boca Raton, 2016, p 75–138

E.A. Levashov, A.S. Mukasyan, A.S. Rogachev and D.V. Shtansky, Self-Propagating High-Temperature Synthesis of Advanced Materials and Coatings, Int. Mater. Rev., 2017, 62(4), p 203–239.

J. Tang, G.C. Saha, P. Richter, J. Kondas, A. Colella and P. Matteazzi, Effects of Post-Spray Heat Treatment on Hardness and Wear Properties of Ti-WC High-Pressure Cold Spray Coatings, J. Therm. Spray Technol., 2018, 27, p 1153–1164.

D. Atong and D.E. Clark, Ignition Behavior and Characteristics of Microwave-Combustion Synthesized Al2O3-TiC Powders, Ceram Int, 2004, 30, p 1909–1912.

Y. Bao, L. Huang, Q. An, S. Jiang, R. Zhang, L. Geng and X. Ma, Insights into Arc-Assisted Self-Propagating High Temperature Synthesis of TiB2-TiC Ceramic Coating via Wire-Arc Deposition, J. Eur. Ceram. Soc., 2020, 40, p 4381–4395.

Y. Yuan, H. Wu, M. You, Z. Li and Y. Zhang, Improving Wear Resistance and Friction Stability of FeNi Matrix Coating by In-Situ Multi-Carbide WC-TiC via PTA Metallurgical Reaction, Surf. Coatings Technol., 2019, 378, p 124957.

Y.S. Tian, C.Z. Chen, D.Y. Wang and T.Q. Lei, Laser Surface Modification of Titanium Alloys—A Review, Surface Rev. Lett., 2005, 12, p 123–130.

W.M. Steen and J. Mazumder, Laser Material Processing, 4th ed. Springer science & business media, Berlin, 2010.

Y.X. Li, J.D. Hu, H.Y. Wang and Z.X. Guo, Study of TiC/Ni3Al Composites by Laser Ignited Self-Propagating High-Temperature Synthesis (LISHS), Chem. Eng. J., 2008, 140(1–3), p 621–625. https://doi.org/10.1016/j.cej.2007.11.034

Y. Li, J. Hu, Y. Liu, Z. Guo and S. Tosto, Effect of Process Parameter on the Combustion Temperature of Laser-Induced Self-Propagating High-Temperature Synthesized Al/TiC Composites, J. Mater. Process. Technol., 2009, 209(5), p 2564–2569. https://doi.org/10.1016/j.jmatprotec.2008.06.001

M. Masanta, S.M. Shariff and A.R. Choudhury, Tribological Behavior of TiB2-TiC-Al2O3 Composite Coating Synthesized by Combined SHS and Laser Technology, Surf. Coatings Technol., 2010, 204, p 2527–2538.

J. Li, C. Chen, Z. Lin and T. Squartini, Phase Constituents and Microstructure of Laser Cladding Al2O3/Ti3Al Reinforced Ceramic Layer on Titanium Alloy, J. Alloys Compd., 2011, 509(14), p 4882–4886. https://doi.org/10.1016/j.jallcom.2011.01.199

T. Yamaguchi and H. Hagino, Formation of Titanium Carbide Layer by Laser Alloying with a Light-Transmitting Resin, Opt. Lasers Eng., 2017, 88, p 13–19.

I. Hulka, D. Utu, V.A. Serban, P. Negrea, F. Lukáč and T. Chráska, Effect of Ti Addition on Microstructure and Corrosion Properties of Laser Cladded WC-Co/NiCrBSi(Ti) Coatings, Appl. Surf. Sci., 2020, 504, p 144349. https://doi.org/10.1016/j.apsusc.2019.144349

K. Ushashri and M. Masanta, Hard TiC Coating on AISI304 Steel by Laser Surface Engineering Using Pulsed Nd:YAG Laser, Mater. Manuf. Process., 2015, 30(6), p 730–735. https://doi.org/10.1080/10426914.2014.973593

A. Chehrghani, M.J. Torkamany, M.J. Hamedi and J. Sabbaghzadeh, Numerical Modeling and Experimental Investigation of TiC Formation on Titanium Surface Pre-Coated by Graphite under Pulsed Laser Irradiation, Appl. Surf. Sci., 2012, 258(6), p 2068–2076. https://doi.org/10.1016/j.apsusc.2011.04.064

M.J. Hamedi, M.J. Torkamany and J. Sabbaghzadeh, Effect of Pulsed Laser Parameters on In-Situ TiC Synthesis in Laser Surface Treatment, Opt. Lasers Eng., 2011, 49(4), p 557–563. https://doi.org/10.1016/j.optlaseng.2010.12.002

H.C. Man, Y.Q. Yang and W.B. Lee, Laser Induced Reaction Synthesis of TiC+WC Reinforced Metal Matrix Composites Coatings on Al 6061, Surf. Coatings Technol., 2004, 185(1), p 74–80.

A. Gisario, M. Barletta and F. Veniali, Laser Surface Modification (LSM) of Thermally-Sprayed Diamalloy 2002 Coating, Opt. Laser Technol., 2012, 44(6), p 1942–1958. https://doi.org/10.1016/j.optlastec.2012.02.011

L. Baiamonte, C. Bartuli, F. Marra, A. Gisario and G. Pulci, Hot Corrosion Resistance of Laser-Sealed Thermal- Sprayed Cermet Coatings, Coatings, 2019, 9(6), p 347.

A. Gisario, M. Puopolo, S. Venettacci and F. Veniali, Improvement of Thermally Sprayed WC-Co/NiCr Coatings by Surface Laser Processing, Int. J. Refract. Met. Hard Mater., 2015, 52, p 123–130. https://doi.org/10.1016/j.ijrmhm.2015.06.001

ASTM E384 - 17, Standard Test Method for Microindentation Hardness of Materials, ASTM Int., 2017, p 1–40.

ASTM G77 - 17, Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test, ASTM Int., 2017.

S. Usmani, S. Sampath, D.L. Houck and D. Lee, Effect of Carbide Grain Size on the Sliding and Abrasive Wear Behavior of Thermally Sprayed WC-Co Coatings, Tribol. Trans., 1997, 40(3), p 470–478.

A. Ibrahim, H. Salem and S. Sedky, Excimer Laser Surface Treatment of Plasma Sprayed Alumina–13% Titania Coatings, Surf. Coatings Technol., 2009, 203(23), p 3579–3589. https://doi.org/10.1016/j.surfcoat.2009.05.034

H. Hiraga, T. Inoue, S. Kamado, Y. Kojima, A. Matsunawa and H. Shimura, Fabrication of NiTi Intermetallic Compound Coating Made by Laser Plasma Hybrid Spraying of Mechanically Alloyed Powders, Surf. Coatings Technol., 2001, 139(1), p 93–100.

M.J. Mas-Guindal, L. Contreras, X. Turrillas, G.B.M. Vaughan, Å. Kvick and M.A. Rodríguez, Self-Propagating High-Temperature Synthesis of TiC–WC Composite Materials, J. Alloys Compd., 2006, 419(1–2), p 227–233.

C. Lyphout, G. Bolelli, E. Smazalova, K. Sato, J. Yamada, Š Houdková, L. Lusvarghi and T. Manfredini, Influence of Hardmetal Feedstock Powder on the Sliding Wear and Impact Resistance of High Velocity Air-Fuel (HVAF)Sprayed Coatings, Wear, 2019, 430–431, p 340–354.

J. Pirso, S. Letunovitš and M. Viljus, Friction and Wear Behaviour of Cemented Carbides, Wear, 2004, 257(3–4), p 257–265.

J.Z. Shao, J. Li, C.C. Qu, R. Song, L.L. Bai and J.L. Chen, Wear Analysis of the Composite Coating in a Long Sliding Time by Dissipated Energy Approach, Sci. Eng. Compos. Mater., 2017, 24(6), p 853–864. https://doi.org/10.1515/secm-2015-0235

Q. Yang, T. Senda and A. Ohmori, Effect of Carbide Grain Size on Microstructure and Sliding Wear Behavior of HVOF-Sprayed WC-12% Co Coatings, Wear, 2003, 254(1–2), p 23–34.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Baiamonte, L., Pulci, G., Gisario, A. et al. WC-Ti Coatings Deposited Via Cold Gas Spray and Modified by Laser and Furnace Heat Treatments. J Therm Spray Tech 30, 2083–2098 (2021). https://doi.org/10.1007/s11666-021-01278-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01278-9