Abstract

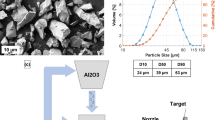

This paper investigated the solid particle erosion behavior of partially oxidized NiCrBSiFe and NiCr coatings by varying temperature and impact angle. The challenge in the current situation is to process a new system of powders containing metallic and oxide phases. Partially oxidized powders containing metallic and oxide phases were processed by flame spraying the alloy powders into distilled water and allowing the oxide layer to form while keeping the core in the middle of the particle. Partially oxidized coatings were developed on MDN321 steel using the plasma spray technique with feedstock of partially oxidized powders. An air jet erosion test was carried out using Al2O3 erodent of grit size 50 µm at room temperature, 200, 400, 600, and 800°C by varying 30, 45, 60, 75, and 90° impact angles. Coatings were characterized concerning bond strength, porosity, micro-hardness, and density. The effect of temperature and impact angle on volumetric erosion loss was studied using SEM, EDS, and XRD analysis. Partially oxidized NiCrBSiFe coating exhibited better erosion resistance compare with partially oxidized NiCr coating. NiCr coating demonstrates maximum volumetric erosion loss at 45° impact angle, whereas NiCrBSiFe at 60° impact angle under all tested temperatures.

Similar content being viewed by others

References

S.B. Mishra, K. Chandra, S. Prakash and B. Venkataraman, Erosion performance of coatings produced by shrouded plasma spray process on a Co-based superalloy, Surf. Coat. Technol., 2006, 201, p 1477–1487.

B. Somasundaram, R. Kadoli and M.R. Ramesh, Evaluation of cyclic oxidation and hot corrosion behavior of HVOF-Sprayed WC-Co/NiCrAlY coating, J. Therm. Spray Technol., 2014, 23(6), p 1000–1008.

E. Bousser, L. Martinu and J.E. Klemberg-Sapieha, Solid particle erosion mechanisms of protective coatings for aerospace applications, Surf. Coat. Technol., 2014, 257, p 165–181.

Y.Q. Xiao, L. Yang, Y.C. Zhou, Y.G. Wei and N.G. Wang, Dominant parameters affecting the reliability of TBCs on a gas turbine blade during erosion by a particle-laden hot gas stream, Wear, 2017, 390–391, p 166–175.

S.B. Mishra, K. Chandra and S. Prakash, Erosion-corrosion performance of NiCrAlY coating produced by plasma spray process in a coal-fired thermal power plant, Surf. Coat. Technol., 2013, 216, p 23–34.

J.B. Cheng, X.B. Liang, Y.X. Chen, Z.H. Wang, and B.S. Xu, High-temperature erosion resistance of FeBSiNb amorphous coatings deposited by arc spraying for boiler applications, J. Therm. Spray Technol., 2013, p 820–827.

H.S. Grewal, H. Singh and A. Agrawal, Microstructural and mechanical characterization of thermal sprayed nickel-alumina composite coatings, Surf. Coat. Technol., 2013, 216, p 78–92.

S. Matthews, B. James and M. Hyland, High temperature erosion-oxidation of Cr3C2-NiCr thermal spray coatings under simulated turbine conditions, Corros. Sci., 2013, 70, p 203–211.

Y. Wang, Y. Yang and M.F. Yan, Microstructures, hardness and erosion behavior of thermal sprayed and heat treated NiAl coatings with different ceria, Wear, 2007, 263, p 371–378.

I.R.V. Geaman, M.A. Pop and D.L. Motoc, Tribological properties of thermal spray coatings, Eur. Sci. J., 2013, 3, p 154–159.

P. Bagde, S.G. Sapate, R.K. Khatirkar and N. Vashishtha, Friction and abrasive wear behaviour of Al2O3-13TiO2 and Al2O3-13TiO2+Ni graphite coatings, Tribol. Int., 2018, 121, p 353–372.

A. Richter, L.M. Berger, Y.J. Sohn, S. Conze, K. Sempf, and R. Vaßen, Impact of Al2O3-40 Wt.% TiO2 feedstock powder characteristics on the sprayability, microstructure and mechanical properties of plasma sprayed coatings, J. Eur. Ceram. Soc., 2019, 39(16), p 5391–5402.

X. Yang, S. Dong, J. Zeng, X. Zhou, J. Jiang, L. Deng, and X. Cao, Sliding wear characteristics of plasma-sprayed Cr2O3 coatings with incorporation of metals and ceramics, Ceram. Int., 2019, p 20243–2025.

K.G. Girisha, K.V. Sreenivas Rao, and C. Durga Prasad, Slurry erosion resistance of martenistic stainless steel with plasma sprayed Al2O3-40%TiO2 coatings, Mater. Today Proc., 2018, 5(2), p 7388–7393.

H.S. Nithin, V. Desai and M.R. Ramesh, Elevated temperature solid particle erosion performance of plasma-sprayed Co-based composite coatings with additions of Al2O3 and CeO2, J. Mater. Eng. Perform., 2017, 26, p 5251–5261.

L. He, Y. Tan, H. Tan, Y. Tu and Z. Zhang, Microstructure and tribological properties of WC-CeO2/Ni-base alloy composite coatings, Rare Met. Mater. Eng., 2014, 43(4), p 823–829.

M.R. Ramesh, S. Prakash, S.K. Nath, P.K. Sapra and B. Venkataraman, Solid particle erosion of HVOF sprayed WC-Co/NiCrFeSiB coatings, Wear, 2010, 269, p 197–205.

Z. Xia, X. Zhang and J. Song, Erosion-resistance of plasma sprayed coatings, J. Mater. Eng. Perform., 1999, 8(6), p 716–718.

K.A. Unocic and B.A. Pint, Oxidation behavior of Co-doped NiCrAl alloys in dry and wet air, Surf. Coat. Technol., 2013, 237, p 8–15.

T. Irisawa and H. Matsumoto, Thermal shock resistance and adhesion strength of plasma-sprayed alumina coating on cast iron, Thin Solid Films, 2006, 509, p 141–144.

A.C. Karaoglanli, H. Dikici and Y. Kucuk, Effects of heat treatment on adhesion strength of thermal barrier coating systems, Eng. Fail. Anal., 2013, 32, p 16–22.

N.C. Reddy, B.S.A. Kumar, M.R. Ramesh and P.G. Koppad, Microstructure and adhesion strength of Ni3Ti coating prepared by mechanical alloying and HVOF, Phys. Met. Metallogr., 2018, 119(5), p 462–468.

T.A. Taylor and P.N. Walsh, Dilatometer studies of NiCrAlY coatings, Surf. Coat. Technol., 2004, 188–189, p 41–48.

S.R. Medabalimi, M. R. Ramesh and R. Kadoli, High-temperature wear and frictional behavior of partially oxidized Al with NiCr composite coating, Mater. Res. Express., IOP Publishing, 2019, 6(12), p 1–13.

J.M. Guilemany, N. Cinca, J. Fernández, and S. Sampath, Erosion, abrasive, and friction wear behavior of iron aluminide coatings sprayed by HVOF, J. Therm. Spray Technol., 2008, p 762–773.

M. Doddamani, M. Mathapati and M.R. Ramesh, Microstructure and tribological behavior of plasma sprayed NiCrAlY / WC- Co / Cenosphere / solid lubricants composite coatings, Surf. Coat. Technol., 2018, 354, p 92–100.

M. Ivosevic, R. Knight, S.R. Kalidindi, G.R. Palmese and J.K. Sutter, Solid particle erosion resistance of thermally sprayed functionally graded coatings for polymer matrix composites, Surf. Coat. Technol., 2006, 200, p 5145–5151.

W. Tillmann, L. Hagen, D. Stangier, I.A. Laemmerhirt, D. Biermann, P. Kersting and E. Krebs, Wear behavior of Bio-inspired and technologically structured HVOF sprayed NiCrBSiFe coatings, Surf. Coat. Technol., 2015, 280, p 16–26.

P. Farahpour, H. Edris, M.M. Kheirikhah, and A.H. Mirrahimi, Influence of high velocity oxy-fuel parameters on the corrosion resistance of NiCr coatings, Proc. Inst. Mech. Eng. Part L: J. Mater. Des. Appl., 2013, 227(4), p 318–335.

C. Huang, L. Du, and W. Zhang, Friction and wear characteristics of plasma-sprayed self-lubrication coating with clad powder at elevated temperatures up to 800 °C, J. Therm. Spray Technol., 2014, p 463–469.

C. Huang, L. Du and W. Zhang, Effects of solid lubricant content on the microstructure and properties of NiCr/Cr3C2-BaF2·CaF2 composite coatings, J. Alloys Compd., 2009, 479, p 777–784.

M. Mathapati, M.R. Ramesh and M. Doddamani, High temperature erosion behavior of plasma sprayed NiCrAlY/WC-Co/Cenosphere coating, Surf. Coat. Technol., 2017, 325, p 98–106.

J.J. Tian, S.W. Yao, X.T. Luo, C.X. Li and C.J. Li, An effective approach for creating metallurgical self-bonding in plasma-spraying of NiCr-Mo coating by designing shell-core-structured powders, Acta. Mater., 2016, 110, p 19–30.

V.H. Hidalgo, F.J.B. Varela, A.C. Menéndez and S.P. Martínez, A Comparative study of high-temperature erosion wear of plasma-sprayed NiCrBSiFe and WC-NiCrBSiFe coatings under simulated coal-fired boiler conditions, Tribol. Int., 2001, 34, p 161–169.

J.M. Miguel, J.M. Guilemany and S. Vizcaino, Tribological study of NiCrBSi coating obtained by different processes, Tribol. Int., 2003, 36, p 181–187.

L. Du, C. Huang, W. Zhang, T. Li and W. Liu, Preparation and wear performance of NiCr/Cr3C2-NiCr/HBN plasma sprayed composite coating, Surf. Coat. Technol., 2011, 205, p 3722–3728.

N. Krishnamurthy, M.S. Murali, B. Venkataraman and P.G. Mukunda, Characterization and solid particle erosion behavior of plasma sprayed alumina and calcia-stabilized zirconia coatings on Al-6061 substrate, Wear, 2012, 274–275, p 15–27.

H.S. Sidhu, B.S. Sidhu and S. Prakash, Comparative characteristic and erosion behavior of NiCr coatings deposited by various high-velocity oxyfuel spray processes, J. Mater. Eng. Perform., 2006, 15(6), p 699–704.

H. Zhang, X. Dong and S. Chen, Solid particle erosion-wear behaviour of Cr3C2-NiCr coating on Ni-based superalloy, Adv. Mech. Eng., 2017, 9(3), p 1–9.

J.K.N. Murthy, K. Satya Prasad, K. Gopinath, and B. Venkataraman, Characterisation of HVOF sprayed Cr3C2-50(Ni20Cr) coating and the influence of binder properties on solid particle erosion behaviour, Surf. Coat. Technol., 2010, 204(24), p 3975–3985.

S. Sharma, High temperature erosive wear study of NiCrFeSiB flame sprayed coatings, J. Inst. Eng. Ser. D., 2012, 93(1), p 7–12.

M. Roy, K.K. Ray and G. Sundararajan, Erosion-oxidation interaction in Ni and Ni-20Cr alloy, Metall. Mater. Trans. A: Phys. Metall. Mater. Sci., 2001, 32A, p 1431–1451.

Acknowledgments

The authors would like to thank “AumTechno Spray Pvt. Ltd Bangalore, India" for providing a research facility to prepare and develop the coatings and to Mr. Sandesh Birla, IIT Bombay, Manufacturing Engineering, for his support to get the 3D profile images from Alicona focus variation microscopy. This research did not receive any financial support from any government or private sector.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Medabalimi, S.R., Ramesh, M.R. & Kadoli, R. High-Temperature Solid Particle Erosion Behavior of Partially Oxidized NiCrBSiFe/NiCr Plasma Spray Coatings. J Therm Spray Tech 30, 1638–1652 (2021). https://doi.org/10.1007/s11666-021-01225-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01225-8