Abstract

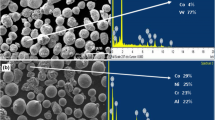

Cavitation erosion is a major damage phenomenon in hydraulic turbine components that is caused by the bubble collapse. Protective coatings are widely applied as a form of surface modification to resist cavitation erosion. In this work, the WC and Cr3C2 cermet coatings were prepared by using HVOF, and their resistances to cavitation erosion in deionized water and 3.5 wt.% NaCl solution were evaluated. The corrosion behavior was investigated by potentiodynamic polarization in 3.5 wt.% NaCl solution, to examine the damaged surface morphologies and the corrosion products. Results indicated that higher hardness and fracture toughness, and lower porosity could enhance cavitation erosion resistance of the coatings in deionized water. In 3.5 wt.% NaCl solution, the cobalt matrix phase of the WC-12Co coating was dissolved in the corrosive solution, which accentuated the cavitation erosion damage. On the contrary, the oxidation product formed on the WC-10Co-4Cr and Cr3C2-NiCr coatings surface in 3.5 wt.% NaCl solution could mitigate delamination, seal surface pores, and protect from cavitation erosion damage. The WC-10Co-4Cr coating with higher hardness, higher toughness, and lower porosity, which exhibited the ability to form surface oxides in the corrosive solution, showed the best cavitation erosion resistance in both deionized water and 3.5 wt.% NaCl solution.

Similar content being viewed by others

References

R. Singh, S.K. Tiwari, and S.K. Mishra, Cavitation Erosion in Hydraulic Turbine Components and Mitigation by Coatings: Current Status and Future Needs, J. Mater. Eng. Perform., 2012, 21(7), p 1539-1551. https://doi.org/10.1007/s11665-011-0051-9

R.K. Kumar, M. Kamaraj, S. Seetharaman, T. Pramod, and P. Sampath Kumaran, Effect of Spray Particle Velocity on Cavitation Erosion Resistance Characteristics of HVOF and HVAF Processed 86WC-10Co4Cr Hydro Turbine coatings, J. Therm. Spray Technol., 2016, 25(6), p 1217-1230. https://doi.org/10.1007/s11666-016-0427-3

C.T. Kwok, F.T. Cheng, and H.C. Man, Synergistic Effect of Cavitation Erosion and Corrosion of Various Engineering Alloys in 3.5% NaCl Solution, Mater. Sci. Eng. A, 2000, 290, p 145-154. https://doi.org/10.1016/s0921-5093(00)00899-6

Q. Wang, S. Zhang, Y. Cheng, X. Jing, X. Zhao, and G. Yang, Wear and Corrosion Performance of WC-10Co4Cr Coatings Deposited by Different HVOF and HVAF Spraying Processes, Surf. Coat. Technol., 2013, 218, p 127-136. https://doi.org/10.1016/j.surfcoat.2012.12.041

G. Taillon, F. Pougoum, S. Lavigne, L. Ton-That, R. Schulz, E. Bousser, S. Savoie, L. Martinu, and J.E. Klemberg-Sapieha, Cavitation Erosion Mechanisms in Stainless Steels and in Composite Metal-Ceramic HVOF Coatings, Wear, 2016, 364–365, p 201-210. https://doi.org/10.1016/j.wear.2016.07.015

Z.X. Ding, Y.M. Hu, and H. Zhao, Structures and Resistance of Cavitation Erosion Micro-nanostructured WC-12Co Coatings Sprayed by HVOF, Tribology, 2013, 33(5), p 429-435. https://doi.org/10.16078/j.tribology.2013.05.008

X. Ding, D. Ke, C.Q. Yuan, Z.X. Ding, and X.D. Cheng, Microstructure and Cavitation Erosion Resistance of HVOF Deposited WC-Co Coatings with Different Sized WC, Coatings, 2018, 8(9), p 307. https://doi.org/10.3390/coatings8090307

S. Lavigne, F. Pougoum, S. Savoie, L. Martinu, J.E. Klemberg-Sapieha, and R. Schulz, Cavitation Erosion Behavior of HVOF CaviTec Coatings, Wear, 2017, 386–387, p 90-98. https://doi.org/10.1016/j.wear.2017.06.003

X.T. Luo, G.M. Smithb, Y. Wang, E. Gildersleeve, S. Sampath, and C.J. Li, Cracking Induced Tribological Behavior Changes for the HVOF WC-12Co Cermet Coatings, Ceram. Int., 2019, 45, p 4718-4728. https://doi.org/10.1016/j.ceramint.2018.11.164

Y. Wang, J. Liu, N. Kang, G. Darut, T. Poirier, J. Stella, H. Liao, and M.P. Planche, Cavitation Erosion of Plasma-Sprayed CoMoCrSi Coatings, Tribol. Int., 2016, 102, p 429-435. https://doi.org/10.1016/j.triboint.2016.06.014

Q. Wang, Z. Tang, and L. Cha, Cavitation and Sand Slurry Erosion Resistances of WC-10Co-4Cr Coatings, J. Mater. Eng. Perform., 2015, 24(6), p 1-9. https://doi.org/10.1007/s11665-015-1496-z

S. Li, Z. Guo, J. Xiong, Y. Lei, Y. Li, J. Tang, J. Liu, and J. Ye, Corrosion Behavior of HVOF Sprayed Hard Face Coatings in Alkaline-Sulfide Solution, Appl. Surf. Sci., 2017, 416, p 69-77. https://doi.org/10.1016/j.apsusc.2017.04.149

Q. Wang, S. Luo, S. Wang, H. Wang, and C.S. Ramachandran, Wear, Erosion and Corrosion Resistance of HVOF-Sprayed WC and Cr3C2 Based Coatings for Electrolytic Hard Chrome Replacement, Int. J. Refract. Metals Hard Mater., 2019, 81, p 242-252. https://doi.org/10.1016/j.ijrmhm.2019.03.010

N. Vashishtha, R.K. Khatirkar, and S.G. Sapate, Tribological Behaviour of HVOF Sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr Coatings, Tribol. Int., 2017, 105, p 55-68. https://doi.org/10.1016/j.triboint.2016.09.025

N. Vashishtha and S.G. Sapate, Abrasive Wear Maps for High Velocity Oxy Fuel (HVOF) Sprayed WC-12Co and Cr3C2-25NiCr Coatings, Tribol. Int., 2017, 114, p 290-305. https://doi.org/10.1016/j.triboint.2017.04.037

A.C. Karaoglanli, M. Oge, K.M. Doleker, and M. Hotamis, Comparison of Tribological Properties of HVOF Sprayed Coatings with Different Composition, Surf. Coat. Technol., 2017, 318, p 299-308. https://doi.org/10.1016/j.surfcoat.2017.02.021

T. Han, C. Deng, X. Zhang, and Q. Liu, A Model of Splats Deposition State and Wear Resistance of WC-10Co4Cr Coating, Ceram. Int., 2018, 44(4), p 4230-4236. https://doi.org/10.1016/j.ceramint.2017.12.003

Z.X. Ding, W. Chen, and Q. Wang, Resistance of Cavitation Erosion of Multimodal WC-12Co Coatings Sprayed by HVOF, Trans. Nonferr. Metals Soc. China, 2011, 21(10), p 2231-2236. https://doi.org/10.1016/S1003-6326(11)61000-5

T. Peat, A.M. Galloway, A.I. Toumpis, and D. Harvey, Evaluation of the Synergistic Erosion-Corrosion Behaviour of HVOF Thermal Spray Coatings, Surf. Coat. Technol., 2016, 299, p 37-48. https://doi.org/10.1016/j.surfcoat.2016.04.072

H. Zhang, Y. Gong, X. Chen, A. McDonald, and H. Li, A Comparative Study of Cavitation Erosion Resistance of several HVOF-Sprayed Coatings in Deionized Water and Artificial Seawater, J. Therm. Spray Technol., 2019, 28(5), p 1060-1071. https://doi.org/10.1007/s11666-019-00869-x

S. Hong, Y. Wu, J. Zhang, Y. Zheng, Y. Zheng, and J. Lin, Synergistic Effect of Ultrasonic Cavitation Erosion and Corrosion of WC-CoCr and FeCrSiBMn Coatings Prepared by HVOF Spraying, Ultrason. Sonochem., 2016, 31, p 563-569. https://doi.org/10.1016/j.ultsonch.2016.02.011

S. Hong, Y. Wu, J. Zhang, Y. Zheng, Y. Qin, and J. Lin, Ultrasonic Cavitation Erosion of High-Velocity Oxygen-Fuel (HVOF) Sprayed Near-Nanostructured WC-10Co-4Cr Coating in NaCl Solution, Ultrason. Sonochem., 2015, 26, p 87-92. https://doi.org/10.1016/j.ultsonch.2016.02.011

G. Hou, X. Zhao, H. Zhou, J. Lu, Y. An, J. Chen, and J. Yang, Cavitation Erosion of Several Oxy-fuel Sprayed Coatings Tested in Deionized Water and Artificial Seawater, Wear, 2014, 311, p 81-92. https://doi.org/10.1016/j.wear.2013.12.026

A.G. Evans and T.R. Wilshaw, Quasi-static Solid Particle Damage in Brittle Solid.-I. Observations Analysis and Implications, Acta Metall., 1976, 24, p 939-956. https://doi.org/10.1016/0001-6160(76)90042-0

C.Q. Yuan, J. Li, C.L. Dong, J. Li, and X.P. Yan, Study on Tribological Properties of Ceramics/Stainless Steel Rubbing Pairs in Hydrogen Peroxide Solutions, Wear, 2011, 271, p 1617-1622. https://doi.org/10.1016/j.wear.2011.01.048

J. Liu, X. Bai, T. Chen, and C. Yuan, Effects of Cobalt Content on the Microstructure, Mechanical Properties and Cavitation Erosion Resistance of HVOF Sprayed Coatings, Coatings, 2019, 9(9), p 534. https://doi.org/10.3390/coatings9090534

E. Sadeghimeresht, N. Markocsan, and P. Nylen, Microstructural Characteristics and Corrosion Behavior of HVAF-and HVOF-Sprayed Fe-Based Coatings, Surf. Coat. Technol., 2017, 318, p 365-373. https://doi.org/10.1016/j.surfcoat.2016.11.088

V.A.D. Souza and A. Neville, Mechanisms and Kinetics of WC-Co-Cr High Velocity Oxy-Fuel Thermal Spray Coating Degradation in Corrosive Environments, J. Therm. Spray Technol., 2006, 15(1), p 106-117. https://doi.org/10.1361/105996306x92677

H. Zhang, Y. Hu, G. Hou, Y. An, and G. Liu, The Effect of High-Velocity Oxy-fuel Spraying Parameters on Microstructure, Corrosion and Wear Resistance of Fe-Based Metallic Glass Coatings, J. Noncryst. Solids, 2014, 406, p 37-44. https://doi.org/10.1016/j.jnoncrysol.2014.09.041

Acknowledgment

This work was supported by the National Natural Science Foundation of China (Grant Number 51422507). The authors express the gratitude to Professor J. Li, Professor Z.X. Ding and Professor H.T. Duan for their support to the experiments of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Chen, T., Yuan, C. et al. Performance Analysis of Cavitation Erosion Resistance and Corrosion Behavior of HVOF-Sprayed WC-10Co-4Cr, WC-12Co, and Cr3C2-NiCr Coatings. J Therm Spray Tech 29, 798–810 (2020). https://doi.org/10.1007/s11666-020-00994-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-00994-y