Abstract

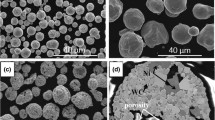

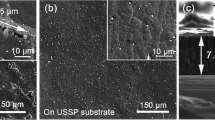

In this research, the effect of the addition of multimodal yttria-stabilized zirconia (YSZ) and SiC reinforcements on the mechanical properties of Cr2O3 plasma-sprayed coatings was studied. For this purpose, the starting powders were ball milled for 5 h and then mixed and agglomerated, prior to spraying. Cr2O3, Cr2O3-20YSZ (CZ), and Cr2O3-20YSZ-10SiC (CZS) coatings were then deposited onto 304L steel substrates using the atmospheric plasma spray process. Microstructural evaluations of the initial/milled powders and the plasma-sprayed coatings were conducted through x-ray diffraction, field emission scanning electron microscopy (FESEM) equipped with energy-dispersive x-ray spectroscopy and porosity measurements. The microscopic images indicated that the multimodal milled powders resulted in nanostructured coatings. Mechanical tests including adhesive strength, fracture toughness, and micro-hardness were used to understand the dependence of the properties of coatings and their microstructure. Adding tough YSZ particles to the C coating considerably increased the toughness through the phase transformation-toughening mechanism of tetragonal zirconia while decreasing micro-hardness of the coating; therefore, intrinsically hard SiC particles were added to the CZ coating to deal with the reduced hardness. Moreover, when compared to pure C coating, CZ, and CZS Composite coatings showed comparable bonding strengths and higher porosities.

Similar content being viewed by others

Data availability

The authors are willing to firstly publish this research paper through the highly prestigious journal of “Thermal Spray Technology”. Therefore the datasets generated and analyzed during the current study have not already been available in public. However, it can be available from the corresponding author on a reasonable request.

Notes

Standard cubic feet per hour.

References

D.J. Green, An Introduction to the Mechanical Properties of Ceramics, Cambridge University Press, Cambridge, 1998

L.L. Mishnaevsky, Jr., Three-dimensional Numerical Testing of Microstructures of Particle Reinforced Composites, J. Acta Mater., 2004, 52(14), p 4177-4188

M.M.E. Rayes, H.S. Abdo, and K.A. Khalil, Erosion-Corrosion of Cermet Coating, J. Electrochem. Sci., 2013, 8, p 1117-1137

R. Banerjee and I. Manna, Ceramic Nanocomposites (Woodhead Publishing, 2013)

E.I.C. Suryanarayana, T. Klassen, and E. Ivanov, Synthesis of Nanocomposites and Amorphous Alloys by Mechanical Alloying, J. Mater. Sci., 2011, 46(19), p 6301-6315

J. Karch, R. Birringer, and H. Gleiter, Ceramics Ductile at Low Temperature, Nature, 1987, 330, p 556-558

W.M. Rainforth, The Wear Behaviour of Oxide Ceramics-A Review, J. Mater. Sci., 2004, 39(22), p 6705-6721

B. Cantor, F.P.E. Dunne, and I.C. Stone, Metal and Ceramic Matrix Composites, 1st edn. (CRC Press, 2003)

B. Basu and K. Balani, Advanced Structural Ceramics, 1st edn. (Wiley-American Ceramic Society, 2011)

A. Vardelle, The 2016 Thermal Spray Roadmap, J. Therm. Spray Technol., 2016, 25(8), p 1376-1440

I. Adamovich, S.D. Baalrud, A. Bogaerts, P.J. Bruggeman, M. Cappelli, V. Colombo, U. Czarnetzki, U. Ebert, J.G. Eden, P. Favia, D.B. Graves, S. Hamaguchi, G. Hieftje, M. Hori, I.D. Kaganovich, U. Kortshagen, M.J. Kushner, N.J. Mason, S. Mazouffre, S.M. Thagard, H.R. Metelmann, A. Mizuno, E. Moreau, A.B. Murphy, B.A. Niemira, G.S. Oehrlein, Z.L. Petrovic, L.C. Pitchford, Y.K. Pu, S. Rauf, O. Sakai, S. Samukawa, S. Starikovskaia, J. Tennyson, K. Terashima, M.M. Turner, M.C.M. Sanden, and A. Vardelle, The 2017 Plasma Roadmap: Low Temperature Plasma Science and Technology, J. Phys. D Appl. Phys., 2017, 2017(50), p 1-46

V. Chawla, B.S. Sidhu, D. Puri, and S. Prakash, Performance of Plasma Sprayed Nanostructured and Conventional Coatings, J. Aust. Ceram. Soc., 2008, 44(2), p 56-62

D. Ghosh, A.K. Shukhla, and H. Roy, Nano Structured Plasma Spray Coating for Wear and High Temperature Corrosion Resistance Applications, J. Inst. Eng.: Series D, 2014, 95(1), p 57-64

M. Gell, E.H. Jordan, Y.H. Sohn, D. Goberman, L. Shaw, and T.D. Xiao, Development and Implementation of plasma Sprayed Nanostructured Ceramic Coatings, Surf. Coatings Technol., 2001, 146, p 48-54

R.S. Lima and B.R. Marple, Thermal Spray Coatings Engineered from Nanostructured Ceramic Agglomerated Powders for Structural, Thermal Barrier and Biomedical Applications: A Review, J. Therm. Spray Technol., 2007, 16(1), p 40-63

N.B. Dahotre and S. Nayak, Nanocoatings for engine application, Surf. Coatings Technol., 2005, 194(1), p 58-67

M. Brochu and G.E. Kim, Anti-Abrasive Nanocoatings Current and Future Applications, chap. 19 (Woodhead Publishing in Materials, 2015)

G. Skandan, R. Yao, B.H. Kear, Y. Qiao, L. Liu, and T.E. Ficsher, Multimodal Powders: A New Class of Feedstock Material for Thermal Spraying of Hard Coatings, Scr. Mater., 2001, 44(8), p 1699-1702

G. Skandan, R. Yao, R. Sadangi, B.H. Kear, Y. Qiao, L. Liu, and T.E. Ficsher, Multimodal Coatings: A New Concept in Thermal Spraying, J. Therm. Spray Technol., 2000, 9(3), p 329-331

J.A. Gan and C.C. Berndt, Nanocomposite Coatings: Thermal Spray Processing, Microstructure and Performance, Int. Mater. Rev., 2014, 60(4), p 195-244

R.F. Bunshah, Handbook of Hard Coatings: Deposition Technolgies, Properties and Applications, 1st edn. (William Andrew, 2000)

G. Bolelli, V. Cannillo, L. Lusvarghi, and T. Manfredini, Wear Behaviour of Thermally Sprayed Ceramic Oxide Coatings, Wear, 2006, 261(11), p 1298-1315

A. Vardelle, Ch Moreau, and N.J. Themelis, A Perspective on Plasma Spray Technology, Plasma Chem. Plasma Process., 2015, 35(3), p 491-509

A. Cellard, V. Garnier, G. Fantozzi, G. Baret, and P. Fort, Wear Resistance of Chromium Oxide Nanostructured Coatings, Ceram. Int., 2009, 35(2), p 913-916

P. Ctibor, I. Pıs, J. Kotlan, I. Khalakhan, V. Stengl, and P. Homola, Microstructure and Properties of Plasma-Sprayed Mixture of Cr2O3 and TiO2, J. Therm. Spray Technol., 2013, 22(7), p 1163-1169

J. Li, Y. Zhang, J. Huang, and C. Ding, Mechanical and Tribological Properties of Plasma-Sprayed Cr3C2-NiCr, WC-Co, and Cr2O3 Coatings, J. Therm. Spray Technol., 1998, 7(2), p 242-246

M. Szafarska and J. Iwaszko, Laser Remelting Teratment of Plasma-Sprayed Cr2O3 Oxide Coatings, Arch. Metall. Mater., 2012, 57(1), p 215-221

D.W. Richerson, Modern Ceramic Engineering: Properties, Processing, and Use in Design, 3rd edn. (CRC Press, 2012)

A. Nusair Khan, J. Lu, and H. Lioa, Heat Treatment of Thermal Barrier Coatings, Mater. Sci. Eng. A, 2003, 359(1), p 129-136

S.T. Aruna, N. Balaji, and K.S. Rajam, Phase Transformation and Wear Studies of Plasma Sprayed Yttria Stabilized Zirconia Coatings Containing Various mol% of Yttria, Mater. Charact., 2011, 62(7), p 697-705

O. Roberts, A.J.G. Lunt, S. Ying, T. Sui, N. Baimpas, I.P. Dolbnya, M. Parkes, D. Dini, S.M. Kreynin, T.K. Neo, and A.M. Korsunsky, A Study of Phase Transformation at the Surface of a Zirconia Ceramic, in: Proc. World Congr. Eng. 2014 Vol 2 (2014, London)

N. Zhang and M.A. Zaeem, Competing Mechanisms between Dislocation and Phase Transformation in Plastic Deformation of Single Crystalline Yttria-Stabilized Tetragonal Zirconia Nanopillars, Acta Mater., 2016, 120, p 337-347

G. Witz, V. Shklover, W. Steurer, S. Bachegowda, and H.P. Bossmann, Phase Evolution in Yttria-Stabilized Zirconia Thermal Barrier Coatings Studied by Rietveld Refinement of X-Ray Powder Diffraction Patterns, Am. Ceram. Soc., 2007, 90(9), p 2935-2940

S. Tao, B. Liang, C. Ding, H. Liao, and C. Coddet, Wear Characteristics of Plasma-Sprayed Nanostructured Yttria Partially Stabilized Zirconia Coatings, J. Therm. Spray Technol., 2005, 14(4), p 518-523

M. Guazzato, M. Albakry, S.P. Ringer, and M.V. Swain, Strength, Fracture Toughness and Microstructure of a Selection of All-ceramic Materials. Part II. Zirconia-based Dental Ceramics, Dental Mater., 2004, 20(5), p 449-456

A.K. Mishra, Ed., Sol-gel Based Nanoceramic Materials: Preparation, Properties and Applications, chap. 2 (Springer International Publishing, 2017)

N. Dejang, A. Limpichaipanit, A. Watcharapasorn, S. Wirojanupatump, P. Niranatlumpong, and S. Jiansirisomboon, Fabrication and Properties of Plasma-Sprayed Al2O3/ZrO2 Composite Coatings, J. Therm. Spray Technol., 2011, 20(6), p 1259-1268

R. Khanna, J. Ong, E. Oral, and R. Narayan, Progress in Wear Resistant Materials for Total Hip Arthroplasty, Coatings, 2017, 7(7), p 99

E. Bakan and R. Vaben, Ceramic Top Coats of Plasma-sprayed Thermal Barrier Coatings: Materials, Processes, and Properties, J. Therm. Spray Technol., 2017, 26(6), p 992-1010

S.R. Choi, D. Zhu, and R.A. Miller, Mechanical Properties/Database of Plasma Sprayed ZrO2-8wt% Y2O3 Thermal Barrier Coatings, Appl. Ceram. Technol., 2005, 1(4), p 330-342

J. Zhao, The Use of Ceramic Matrix Composites for Metal Cutting Applications, Advances in Ceramic Matrix Composites (Elsevier, 2014), pp. 623–654

S.Y. Liu, Y. Wang, C. Zhou, and Z.Y. Pan, Mechanical Properties and Tribological Behavior of Alumina/Zirconia Composites Modified with SiC and Plasma Treatment, Wear, 2015, 332–333, p 885-890

Z.Y. Pan, Y. Wang, X.W. Li, C.H. Wang, and Z.W. Zou, Effect of Submicron and Nano SiC Particles on Erosion Wear and Scratch Behavior of Plasma-Sprayed Al2O3/8YSZ Coatings, J. Therm. Spray Technol., 2012, 21(5), p 995-1010

J. Lin, Y. Huang, and H. Zhang, Damage Resistance, R-curve Behavior and Toughening Mechanisms of ZrB2-based Composites with SiC Whiskers and ZrO2 Fibers, Ceram. Int., 2015, 41(2), p 2690-2698

L. Chen, Y. Wang, H. Shen, J. Rao, and Y. Zhou, Effect of SiC Content on Mechanical Properties and Thermal Shock Resistance of BN-ZrO2-SiC composites, Mater. Sci. Eng., A, 2014, 590, p 346-351

J.O. Berghaus, J.G. Legoux, Ch Moreau, F. Tarasi, and T. Chraska, Mechanical and Thermal Transport Properties of Suspension Thermal-Sprayed Alumina-Zirconia Composite Coatings, J. Therm. Spray Technol., 2008, 17(1), p 91-104

F.M. Katubilwa and M.H. Moys, Effect of Ball Size Distribution on Milling Rate, Miner. Eng., 2009, 22(15), p 1283-1288

K.M. Kabezya and H. Motjotji, The Effect of Ball Size Diameter on Milling Performance, J. Mater. Sci. Eng., 2014, 4(1), p 1-3

N. Hlabangana, G. Danha, and E. Muzenda, Effect of Ball and Feed Particle Size Distribution on the Milling Efficiency of a Ball Mill: An Attainable Region Approach, S. Afr. J. Chem. Eng., 2018, 25, p 79-84

H. Ghayour, M. Abdellahi, and M. Bahmanpour, Optimization of the High Energy Ball-milling: Modeling and Parametric Study, Powder Technol., 2016, 291, p 7-13

M.K. Singla, H. Singh, and V. Chawla, Thermal Sprayed CNT Reinforced Nanocomposite Coatings-A Review, J. Miner. Mater. Charact. Eng., 2011, 10(8), p 717-726

P. Bengtsson and C. Persson, Modelled and Measured Residual Stresses in Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 1997, 92(1–2), p 78-86

S. Chandra and P. Fauchais, Formation of Solid Splats During Thermal Spray Deposition, J. Therm. Spray Technol., 2009, 18(2), p 148-180

C. Li, X. Zhang, Y. Chen, J. Carr, S. Jacques, J. Behnsen, M. Di Michiel, P. Xiao, and R. Cernik, Understanding the Residual Stress Distribution Through the Thickness of Atmosphere Plasma Sprayed (APS) Thermal Barrier Coatings (TBCs) By High Energy Synchrotron Xrd; Digital Image Correlation (DIC) and Image Based Modelling, Acta Mater., 2017, 132, p 1-12

K. Yang, X. Zhou, C. Liu, S. Tao, and C. Ding, Sliding Wear Performance of Plasma-Sprayed Al2O3-Cr2O3 Composite Coatings Against Graphite under Severe Conditions, J. Therm. Spray Technol., 2013, 22(7), p 1154-1162

R.C. Tucker, Ed., ASM Handbook, Vol 5A, Thermal Spray Technology, ASM International, Russell, 2013

G.K. Beshish, C.W. Florey, F.J. Worzala, and W.J. Lenling, Fracture Toughness of Thermal Spray Ceramic Coatings Determined by the Indentation Technique, J. Therm. Spray Technol., 1993, 2(1), p 35-38

A.G. Evans and E.A. Charles, Fracture Toughness Determinations by Indentation, J. Am. Cer. Soc., 1976, 59(7–8), p 371-372

A. Nastic, A. Merati, M. Bielawski, M. Bolduc, O. Fakolujo, and M. Nganbe, Instrumented and Vickers Indentation for the Characterization of Stiffness, Hardness and Toughness of Zirconia Toughened Al2O3 and SiC Armor, J. Mater. Sci. Tech., 2015, 31(8), p 773-783

A. Moradkhani, H. Baharvandi, M. Tajdari, H. Latifi, and J. Martikainen, Determination of Fracture Toughness using the Area of Micro-Crack Tracks Left in Brittle Materials by Vickers Indentation Test, J. Adv. Cer., 2013, 2(1), p 87-102

G.D. Quinn, Fracture Toughness of Ceramics by the Vickers Indentation Crack Length Method A Critical Review, Ceram. Eng. Sci. Proc., 2007, 27(3), p 45-62

D. Coric, L. Curkovic, and M.M. Renjo, Statistical Analysis of Vickers Indentation Fracture Toughness of Y-TZP Ceramics, Trans. Famena, 2017, 41(2), p 1-16

A.S. Deliormanli and M. Guden, Microhardness and Fracture Toughness of Dental Materials by Indentation Method, J. Biomedical Mater. Res., 2006, 76(2), p 257-264

Y. Feng and T. Zhang, Determination of Fracture Toughness of Brittle materials by Indentation, Acta Mech. Sol. Sin., 2015, 28(3), p 221-234

K. Tanaka, Elastic-plastic Indentation Hardness and Indentation Fracture Toughness, the Inclusion Core Model, J. Mater. Sci., 1987, 22(4), p 1501-1508

B.R. Lawn and E.R. Fuller, Equilibrium Penny-like Cracks in Indentation Fracture, J. Mater. Sci., 1975, 10(12), p 2016-2024

A.G. Evans and T.R. Wilshaw, Quasi-Static Solid Particle Damage in Brittle Solids, Observations, Analysis and Implications, Acta Metall., 1976, 24(10), p 939-956

D.K. Shetty, I.G. Wright, P.N. Mincer, and A.H. Clauer, Indentation Fracture of WC-Co Cermets, J. Mater. Sci., 1985, 20(5), p 1873-1882

K. Niihara, R. Morena, and D.P.H. Hasselman, Evaluation of KIC of Brittle Solids by the Indentation Method with Low Crack-to-Indent Ratios, J. Mater. Sci. Let., 1982, 1(1), p 13-16

P. Zamani and Z. Valefi, Microstructure, Phase Composition and Mechanical Properties of Plasma Sprayed Al2O3, Cr2O3, and Cr2O3-Al2O3 Composite Coatings, Surf. Coat. Technol., 2017, 316, p 138-145

P. Fauchais, G. Montavon, and G. Bertrand, From Powders to Thermally Sprayed Coatings, J. Therm. Spray Technol., 2010, 19(1–2), p 56-80

M. Harju, T. Mantyla, K. Vaha-Heikkila, and V.P. Lehto, Water Adsorption on Plasma Sprayed Transition Metal Oxides, Appl. Surf. Sci., 2005, 249(1-4), p 115-126

M. Toozandehjani, K.A. Matori, F. Ostovan, S. Abdul Aziz, and M.S. Mamat, Effect of Milling Time on the Microstructure, Physical and Mechanical Properties of Al-Al2O3 Nanocomposite Synthesized by Ball Milling and Powder Metallurgy, Materials (Basel), 2017, 10(11), p 1-17

J.B. Rao, G.J. Catherin, I.N. Murthy, D.V. Rao, and B.N. Raju, Production of Nano Structured Silicon Carbide by High Energy Ball Milling, Int. J. Eng. Sci. Technol., 2011, 3(4), p 82-88

G. Rajender and P.K. Giri, Strain Induced Phase Formation, Microstructural Evolution and Bandgap Narrowing in Strained TiO2 Nanocrystals Grown by Ball Milling, J. Alloys Comp., 2016, 676, p 591-600

C.P. Gazzara, The Measurement of Residual Stress with x-ray Diffraction (Army materials and mechanics research center, 1983)

A. Bahera and S.C. Mishra, Prediction and Analysis of Deposition Efficiency of Plasma Spray Coating using Artificial Intelligence Method, Compos. Mater., 2012, 2(2), p 54-60

V.P. Singh, A. Sil, and R. Jayaganthan, Wear of Plasma Sprayed Conventional and Nanostructured Al2O3 and Cr2O3, Based Coatings, Trans. Indian Inst. Met., 2012, 65(1), p 1-12

D.G. Goberman, Microstructure Investigation of Plasma Sprayed Alumina 13 Weight Percent Titania Coatings from Nanocrystalline Feed Powders, Ph.D. Thesis, University of Connecticut, 2002

F. Onoue and K. Tsuji, X-Ray Elemental Imaging in Depth by Combination of FE-SEM-EDS and Glow Discharge Sputtering, ISIJ Int., 2013, 53(11), p 1939-1942

W. Chi, S. Sampath, and H. Wang, Ambient and High-temperature Thermal Conductivity of Thermal Sprayed Coatings, J. Therm. Spray Technol., 2006, 15(4), p 773-778

K.W. Schlichting, N.P. Padture, and P.G. Klemens, Thermal Conductivity of Dense and Porous Yttria-stabilized Zirconia, Mater. Sci., 2001, 36(12), p 3003-3010

E.M. Garcia, Optimizing the Sintering of Cr 2 O 3-nano Powders for HVOF Applications, M.Sc. Thesis, the University Carlos III of Madrid, 2012

R.G. Munro, Material Properties of a Sintered α-SiC, Phys. Chem. Ref. Data., 2009, 26(5), p 1195-1205

J. Zhang and V. Desai, Evaluation of Thickness, Porosity and Pore Shape of Plasma Sprayed TBC by Electrochemical Impedance Spectroscopy, Surf. Coatings Technol., 2005, 190(1), p 98-109

C.B. Ponton and R.D. Rawlings, Vickers Indentation Fracture Toughness Test Part 1 Review of Literature and Formulation of Standardised Indentation Toughness Equations, Mater. Sci. Tech., 1989, 5(9), p 865-872

T.A. Fabijanic, D. Coric, M.S. Musa, and M. Sakoman, Vickers Indentation Fracture Toughness of Near-Nano and Nanostructured WC-Co Cemented Carbides, Metals, 2017, 7, p 143-159

M. Kutz, Handbook of Materials Selection, Wiley, NY, 2002

A.G. Gogotsi, Fracture Toughness of Ceramics and Ceramic Composites, Ceram. Int., 2003, 29, p 777-784

Y. Takano, T. Komeda, M. Yoshinaka, K. Hirota, and O. Yamaguchi, Fabrication, Microstructure, and Mechanical Properties of Cr2O3/ZrO2(2.5Y) Composite Ceramics in the Cr2O3-Rich Region, Am. Ceram. Soc., 1998, 81, p 2497-2500

R.C. Bradt, D.P.H. Hasselman, and D. Munz, Fracture Mechanics of Ceramics, Vol 12, Composites, and High Temperature Behavior, Springer Science + Business Media New York, Fatigue, 1996

R.W. Rice, Grain Size and Porosity Dependence of Ceramic Fracture Energy and Toughness at 22 °C, J. Mater. Sci., 1996, 31(8), p 1969-1983

D.L. Zhang, J. Liang, and J. Wu, Processing Ti3Al-SiC Nanocomposites using High Energy Mechanical Milling, Mater. Sci. Eng., A, 2004, 375–377, p 911-916

R. Gadow, M.J. Riegert-Escribano, and M. Buchmann, Residual Stress Analysis in Thermally Sprayed Layer Composites, Using the Hole Milling and Drilling Method, J. Therm. Spray Technol., 2005, 14, p 100-108

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hashemi, S.M., Parvin, N. & Valefi, Z. Effect of Addition of Multimodal YSZ and SiC Powders on the Mechanical Properties of Nanostructured Cr2O3 Plasma-Sprayed Coatings. J Therm Spray Tech 28, 544–562 (2019). https://doi.org/10.1007/s11666-019-00834-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00834-8