Abstract

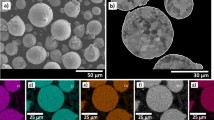

Four Sm2Zr2O7 (SZO) powders with different morphologies were deposited by atmospheric plasma spraying on superalloy substrates using the same spraying parameters. Both the particle size distribution and microstructure of the powders had an important effect on the coating microstructure. SZO thermal barrier coatings (TBCs) deposited using the powder with a narrow particle size distribution showed a better “molten state” and exhibited a higher average bonding strength compared with the SZO TBCs deposited using the powder with a wide particle size distribution. The dense microstructure of the calcined powder sintered at high temperature and of the powder spheroidized by plasma spraying gun (SF) improved the melting capacity of the powders, and the resulting coatings showed a compact microstructure with unique bimodal structures. Furthermore, the SF SZO TBCs presented an excellent “molten state” with a smooth surface and exhibited a high bonding strength of 29.6 ± 0.15 MPa.

Similar content being viewed by others

References

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gasturbine Engine Applications, Science, 2002, 296, p 279-284

E. Bakan and R. Vaßen, Ceramic Top Coats of Plasma-Sprayed Thermal Barrier Coatings: Materials, Processes, and Properties, J. Therm. Spray Technol., 2017, 26(6), p 992-1010

C.U. Hardwicke and Y.C. Lau, Advances in Thermal Spray Coatings for Gas Turbines and Energy Generation: A Review, J. Therm. Spray Technol., 2013, 22, p 564-576

W.W. Zhang, G.R. Li, Q. Zhang, and G.J. Yang, Comprehensive Damage Evaluation of Localized Spallation of Thermal Barrier Coatings, J. Adv. Ceram., 2017, 6(3), p 230-239

R. Vassen, X.Q. Cao, F. Tietz, D. Basu, and D. Stöver, Zirconates as New Material for Thermal Barrier Coatings, J. Am. Ceram. Soc., 2000, 83(8), p 2023-2028

H. Lehmann, D. Pitzer, G. Pracht, R. Vassen, and D. Stöver, Thermal Conductivity and Thermal Expansion Coefficients of the Lanthanum Rare-Earth-Element Zirconate System, J. Am. Ceram. Soc., 2003, 86(8), p 1338-1344

N. Nakanishi and T. Shigematsu, Martensitic Transformations in Zirconia Ceramics, Mater. Trans., 1992, 33(3), p 318-323

X.Q. Cao, R. Vassen, and D. Stoever, Ceramic Materials for Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2004, 24, p 1-10

S.A. Tsipas, Effect of Dopants on the Phase Stability of Zirconia-Based Plasma Sprayed Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2010, 30, p 61-72

X.Q. Cao, R. Vassen, W. Jungen, S. Schwartz, F. Tietz, and D. Stover, Thermal Stability of Lanthanum Zirconate Plasma-Sprayed Coating, J. Am. Ceram. Soc., 2001, 84(9), p 2086-2090

T. Liu, X.T. Luo, X. Chen, G.J. Yang, C.X. Li, and C.J. Li, Morphology and Size Evolution of Interlamellar Two-dimensional Pores in Plasma-Sprayed La2Zr2O7 Coatings During Thermal Exposure at 1300 °C, J. Therm. Spray Technol., 2015, 24(5), p 739-748

R. Vassen, M.O. Jarligo, T. Steinke, D.E. Mack, and D. Stover, Overview on Advanced Thermal Barrier Coatings, Surf. Coat. Technol., 2010, 205(4), p 938-942

L.L. Cai, W. Ma, B. Ma, F. Guo, W.D. Chen, H.Y. Dong, and Y.C. Shuang, Air Plasma-Sprayed La2Zr2O7-SrZrO3 Composite Thermal Barrier Coating Subjected to CaO-MgO-Al2O3-SiO2 (CMAS), J. Therm. Spray Technol., 2017, 26(6), p 1076-1083

Y. Li, C.J. Li, G.J. Yang, and C.X. Li, Relation Between Microstructure and Thermal Conductivity of Plasma-Sprayed 8YSZ Coating, Int. J. Mod. Phys. B, 2010, 24, p 3017-3022

Q.B. Fan, F. Zhang, F.C. Wang, and L. Wang, Molecular Dynamics Calculation of Thermal Expansion Coefficient of a Series of Rare-Earth Zirconates, Comput. Mater. Sci., 2009, 46, p 716-719

A. Sharma, T. Dudykevych, D. Sansom, and R. Subramanian, Increased Reliability of Gas Turbine Components by Robust Coatings Manufacturing, J. Therm. Spray Technol., 2017, 26(6), p 1084-1094

H.X. Wu, Z. Ma, L. Liu, Y.B. Liu, and D.Y. Wang, Thermal Cycling Behavior and Bonding Strength of Single-Ceramic-Layer Sm2Zr2O7, and Double-Ceramic-Layer Sm2Zr2O7 /8YSZ Thermal Barrier Coatings Deposited by Atmospheric Plasma Spraying, Ceram. Int., 2016, 42(11), p 12922-12927

P. Carpio, R. Moreno, A. Gómez, M.D. Salvador, and E. Sánchez, Role of Suspension Preparation in the Spray Drying Process to Obtain Nano/Submicrostructured YSZ Powders for Atmospheric Plasma Spraying, J. Eur. Ceram. Soc., 2015, 35(1), p 237-247

A.H. Pakseresht, M.R. Rahimipour, M.R. Vaezi, and M. Salehi, Thermal Plasma Spheroidization and Spray Deposition of Barium Titanate Powder and Characterization of the Plasma Sprayable Powder, Mater. Chem. Phys., 2016, 173, p 395-403

P. Fauchais, Topical Review: Understanding Plasma Spraying, J. Appl. Phys., 2004, 37(9), p 86-108

L.L. Shaw, D. Goberman, R. Ren, M. Gell, S. Jiang, Y. Wang, T.D. Xiao, and P.R. Strutt, The Dependency of Microstructure and Properties of Nanostructured Coatings on Plasma Spray Conditions, Surf. Coat. Technol., 2000, 130(1), p 1-8

D.R. Clarke, Materials Selection Guidelines for Low Thermal Conductivity Thermal Barrier Coatings, Surf. Coat. Technol., 2003, 163-164(02), p 67-74

W.G. Chi, S. Sampath, and H. Wang, Microstructure-Thermal Conductivity Relationships for Plasma-Sprayed Yttria-Stabilized Zirconia Coatings, J. Am. Ceram. Soc., 2008, 91, p 2636-2645

J.A. Thompson and T.W. Clyne, The Effect of Heat Treatment on the Stiffness of Zirconia Top Coats in Plasma-Sprayed TBCs, Acta Mater., 2001, 49, p 1565-1575

R.S. Lima, S.E. Kruger, G. Lamouche, and B.R. Marple, Elastic Modulus Measurements via Laser-Ultrasonic and Knoop Indentation Techniques in Thermally Sprayed Coatings, J. Therm. Spray Technol., 2005, 14, p 52-60

S. Guo and Y. Kagawa, Young’s Moduli of Zirconia Top-Coat and Thermally Grown Oxide in a Plasma-Sprayed Thermal Barrier Coating System, Scripta Mater., 2004, 50, p 1401-1406

Y. Tan, A. Shyam, W.B. Choi, E. Lara-Curzio, and S. Sampath, Anisotropic Elastic Properties of Thermal Spray Coatings Determined via Resonant Ultrasound Spectroscopy, Acta Mater., 2010, 58, p 5305-5315

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51772027).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, W., Ma, Z., Liu, L. et al. Influence of Feedstock on the Microstructure of Sm2Zr2O7 Thermal Barrier Coatings Deposited by Plasma Spraying. J Therm Spray Tech 27, 1524–1531 (2018). https://doi.org/10.1007/s11666-018-0803-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0803-2