Abstract

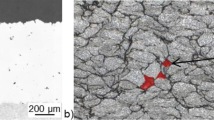

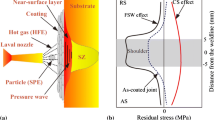

Cold spray bonding (CSB) has been proposed as a new method for joining aluminum and copper. At high speeds, solid Al particles impacted the groove between the two substrates to form a bond between Al and Cu. Compared to traditional welding technologies, CSB does not form distinct intermetallic compounds. Large stainless steel particles were introduced into the spray powders as in situ shot peen particles to create a dense Al deposit and to improve the bond strength of joints. It was discovered that introducing shot peen particles significantly improved the flattening ratio of the deposited Al particles. Increasing the proportion of shot peen particles from 0 to 70 vol.% decreased the porosity of the deposits from 12.4 to 0.2%, while the shear strength of joints significantly increased. The tensile test results of the Al-Cu joints demonstrated that cracks were initiated at the interface between the Al and the deposit. The average tensile strength was 71.4 MPa and could reach 81% of the tensile strength of pure Al.

Similar content being viewed by others

References

S.D. Meshram, T. Mohandas, and G.M. Reddy, Friction Welding of Dissimilar Pure Metals, J. Mater. Process. Technol., 2007, 184(1-3), p 330-337

K.P. Mehta and V.J. Badheka, A Review on Dissimilar Friction Stir Welding of Copper to Aluminum: Process, Properties, and Variants, Mater. Manuf. Process., 2015, 31(3), p 233-254

Z. Sun and R. Karppi, The Application of Electron Beam Welding for the Joining of Dissimilar Metals: An Overview, J. Mater. Process. Technol., 1996, 59(3), p 257-267

J.E. Lee, D.H. Bae, W.S. Chung, K.H. Kim, J.H. Lee, and Y.R. Cho, Effects of Annealing on the Mechanical and Interface Properties of Stainless Steel/Aluminum/Copper Clad-Metal Sheets, J. Mater. Process. Technol., 2007, 187-188, p 546-549

J.-P. Immarigeon, R.T. Holt, A.K. Koul, L. Zhao, W. Wallace, and J.C. Beddoes, Lightweight Materials for Aircraft Applications, Trans. Indian Inst. Met., 2016, 70(1), p 125-131

A. Safarzadeh, M. Paidar, and H. Youzbashi-zade, A Study on the Effects Bonding Temperature and Holding Time on Mechanical and Metallurgical Properties of Al-Cu Dissimilar Joining by DFW, Trans. Indian Inst. Met., 2016, 70(1), p 125-131

M. Akbari, P. Bahemmat, M. Haghpanahi, and M.K. Besharati, Givi, Enhancing Metallurgical and Mechanical Properties of Friction Stir Lap Welding of Al-Cu Using Intermediate Layer, Sci. Technol. Weld. Join., 2013, 18(6), p 518-524

H.J. Liu, J.J. Shen, S. Xie, Y.X. Huang, F. Cui, C. Liu, and L.Y. Kuang, Weld Appearance and Microstructural Characteristics of Friction Stir Butt Barrier Welded Joints of Aluminium Alloy to Copper, Sci. Technol. Weld. Join., 2013, 17(2), p 104-110

H.J. Liu, J.J. Shen, L. Zhou, Y.Q. Zhao, C. Liu, and L.Y. Kuang, Microstructural Characterisation and Mechanical Properties of Friction Stir Welded Joints of Aluminium Alloy to Copper, Sci. Technol. Weld. Join., 2013, 16(1), p 92-98

I. Galvão, J.C. Oliveira, A. Loureiro, and D.M. Rodrigues, Formation and Distribution of Brittle Structures in Friction Stir Welding of Aluminium and Copper: Influence of Shoulder Geometry, Intermetallics, 2012, 22, p 122-128

J. Nishiwaki, T. Kambe, Y. Kedo, Y. Harada, S. Muraishi, and S. Kumai, Numerical Analysis of Wavy Interface Formation and Successive Temperature Change in Magnetic Pulse Welded Al/Cu Joint, Mater. Sci. Forum, 2016, 877, p 655-661

W. Shi, W. Wang, and Y. Huang, Laser Micro-welding of Cu-Al Dissimilar Metals, Int. J. Adv. Manuf. Technol., 2015, 85(1-4), p 185-189

P.C. Seshagiri, G. Madhusudan Reddy, K. Srinivasa Rao, M. Govinda Raju, S.S. Bhattacharya, and K. Prasad Rao, Microstructure and Mechanical Properties of Sc modified Al-Cu Alloy (AA2219) Electron Beam Welds, Sci. Technol. Weld. Join., 2013, 13(5), p 415-421

B. Gulenc, Investigation of Interface Properties and Weldability of Aluminum and Copper Plates by Explosive Welding Method, Mater. Des., 2008, 29(1), p 275-278

M. Sedighi and M. Honarpisheh, Experimental Study of Through-Depth Residual Stress in Explosive Welded Al-Cu-Al Multilayer, Mater. Des., 2012, 37, p 577-581

H. Amani and M. Soltanieh, Intermetallic Phase Formation in Explosively Welded Al/Cu Bimetals, Metal. Mater. Trans. B, 2016, 47(4), p 2524-2534

C.Z. Xia, Y.J. Li, J. Wang, and H.J. Ma, Microstructure and Phase Constitution Near Interface of Cu/Al Vacuum Brazing, Mater. Sci. Technol., 2013, 23(7), p 815-818

J. Peng, S. Fukumoto, L. Brown, and N. Zhou, Image Analysis of Electrode Degradation in Resistance Spot Welding of Aluminium, Sci. Technol. Weld. Join., 2013, 9(4), p 331-336

M.N. Avettand-Fenoël, R. Taillard, G. Ji, and D. Goran, Multiscale Study of Interfacial Intermetallic Compounds in a Dissimilar Al 6082-T6/Cu Friction-Stir Weld, Metal. Mater. Trans. A, 2012, 43(12), p 4655-4666

I. Galvão, A. Loureiro, D. Verdera, D. Gesto, and D.M. Rodrigues, Influence of Tool Offsetting on the Structure and Morphology of Dissimilar Aluminum to Copper Friction-Stir Welds, Metal. Mater. Trans. A, 2012, 43(13), p 5096-5105

P. Xue, B.L. Xiao, D.R. Ni, and Z.Y. Ma, Enhanced Mechanical Properties of Friction Stir Welded Dissimilar Al-Cu Joint by Intermetallic Compounds, Mater. Sci. Eng. A, 2010, 527(21-22), p 5723-5727

C.W. Tan, Z.G. Jiang, L.Q. Li, Y.B. Chen, and X.Y. Chen, Microstructural Evolution and Mechanical Properties of Dissimilar Al-Cu Joints Produced by Friction Stir Welding, Mater. Des., 2013, 51, p 466-473

P. Xue, D.R. Ni, D. Wang, B.L. Xiao, and Z.Y. Ma, Effect of Friction Stir Welding Parameters on the Microstructure and Mechanical Properties of the Dissimilar Al-Cu Joints, Mater. Sci. Eng. A, 2011, 528(13-14), p 4683-4689

R.C. Dykhuizen and M.F. Smith, Gas Dynamic Principles of Cold Spray, J. Therm. Spray Technol., 1998, 7(2), p 205-212

M. Grujicic, C.L. Zhao, C. Tong, W.S. DeRosset, and D. Helfritch, Analysis of the Impact Velocity of Powder Particles in the Cold-Gas Dynamic-Spray Process, Mater. Sci. Eng. A, 2004, 368(1-2), p 222-230

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

R. Ghelichi, D. MacDonald, S. Bagherifard, H. Jahed, M. Guagliano, and B. Jodoin, Microstructure and Fatigue Behavior of Cold Spray Coated Al5052, Acta Mater., 2012, 60(19), p 6555-6561

W.Y. Li, D.D. Zhang, C.J. Huang, S. Yin, M. Yu, F.F. Wang, and H.L. Liao, Modelling of Impact Behaviour of Cold Spray Particles: Review, Surf. Eng., 2014, 30(5), p 299-308

X. Meng, J. Zhang, J. Zhao, Y. Liang, and Y. Zhang, Influence of Gas Temperature on Microstructure and Properties of Cold Spray 304SS Coating, J. Mater. Sci. Technol., 2011, 27(9), p 809-815

V.K. Champagne, M.K. West, M. Reza Rokni, T. Curtis, V. Champagne, and B. McNally, Joining of Cast ZE41A Mg to Wrought 6061 Al by the Cold Spray Process and Friction Stir Welding, J. Therm. Spray Technol., 2015, 25(1-2), p 143-159

X.-T. Luo, C.-X. Li, F.-L. Shang, G.-J. Yang, Y.-Y. Wang, and C.-J. Li, High Velocity Impact Induced Microstructure Evolution During Deposition of Cold Spray Coatings: A Review, Surf. Coat. Technol., 2014, 254, p 11-20

H. Bu, M. Yandouzi, C. Lu, D. MacDonald, and B. Jodoin, Cold Spray Blended Al+Mg17Al12 Coating for Corrosion Protection of AZ91D Magnesium alloy, Surf. Coat. Technol., 2012, 207, p 155-162

E. Sansoucy, P. Marcoux, L. Ajdelsztajn, and B. Jodoin, Properties of SiC-Reinforced Aluminum Alloy Coatings Produced by the Cold Gas Dynamic Spraying Process, Surf. Coat. Technol., 2008, 202(16), p 3988-3996

Y.-K. Wei, X.-T. Luo, C.-X. Li, and C.-J. Li, Optimization of in situ Shot-Peening-Assisted Cold Spraying Parameters for Full Corrosion Protection of Mg Alloy by Fully Dense Al-Based Alloy Coating, J. Therm. Spray Technol., 2016, 26(1-2), p 173-183

X.-T. Luo, Y.-K. Wei, Y. Wang, and C.-J. Li, Microstructure and Mechanical Property of Ti and Ti6Al4 V Prepared by an in situ Shot Peening Assisted Cold Spraying, Mater. Des., 2015, 85, p 527-533

Z. Arabgol, H. Assadi, T. Schmidt, F. Gärtner, and T. Klassen, Analysis of Thermal History and Residual Stress in Cold-Sprayed Coatings, J. Therm. Spray Technol., 2013, 23(1-2), p 84-90

S. Cho, K. Takagi, H. Kwon, D. Seo, K. Ogawa, K. Kikuchi, and A. Kawasaki, Multi-walled Carbon Nanotube-reinforced Copper Nanocomposite Coating Fabricated by Low-pressure Cold Spray Process, Surf. Coat. Technol., 2012, 206(16), p 3488-3494

S. Dosta, M. Couto, and J.M. Guilemany, Cold Spray Deposition of a WC-25Co Cermet onto Al7075-T6 and Carbon Steel Substrates, Acta Mater., 2013, 61(2), p 643-652

H. Lee and K. Ko, Effect of SiC Particle Size on Cold Sprayed Al-SiC Composite Coatings, Surf. Eng., 2013, 25(8), p 606-611

K. Spencer, D.M. Fabijanic, and M.X. Zhang, The Use of Al-Al2O3 Cold Spray Coatings to Improve the Surface Properties of Magnesium Alloys, Surf. Coat. Technol., 2009, 204(3), p 336-344

C.-J. Li and W.-Y. Li, Deposition Characteristics of Titanium Coating in Cold Spraying, Surf. Coat. Technol., 2003, 167(2-3), p 278-283

B.S. Deforce, T.J. Eden, and J.K. Potter, Cold Spray Al-5% Mg Coatings for the Corrosion Protection of Magnesium Alloys, J. Therm. Spray Technol., 2011, 20(6), p 1352-1358

M. Diab, X. Pang, and H. Jahed, The Effect of Pure Aluminum Cold Spray Coating on Corrosion and Corrosion Fatigue of Magnesium (3% Al-1% Zn) Extrusion, Surf. Coat. Technol., 2016, 309, p 423-435

E. Irissou, J.G. Legoux, B. Arsenault, and C. Moreau, Investigation of Al-Al2O3 Cold Spray Coating Formation and Properties, J. Therm. Spray Technol., 2007, 16(5-6), p 661-668

G. Li, X.-F. Wang, and W.-Y. Li, Effect of Different Incidence Angles on Bonding Performance in Cold Spraying, Trans. Nonferr. Met. Soc. Chin., 2007, 17(1), p 116-121

C.-J. Li, W.-Y. Li, Y.-Y. Wang, G.-J. Yang, and H. Fukanuma, A Theoretical Model for Prediction of Deposition Efficiency in Cold Spraying, Thin Solid Films, 2005, 489(1-2), p 79-85

C. Otten, U. Reisgen, and M. Schmachtenberg, Electron Beam Welding of Aluminum to Copper: Mechanical Properties and Their Relation to Microstructure, Weld. World, 2015, 60(1), p 21-31

Q.-Z. Zhang, W.-B. Gong, and W. Liu, Microstructure and Mechanical Properties of Dissimilar Al-Cu Joints by Friction Stir Welding, Trans. Nonferr. Met. Soc. Chin., 2015, 25(6), p 1779-1786

S.A. Khodir, M.M.Z. Ahmed, E. Ahmed, S.M.R. Mohamed, and H. Abdel-Aleem, Effect of Intermetallic Compound Phases on the Mechanical Properties of the Dissimilar Al/Cu Friction Stir Welded Joints, J. Mater. Eng. Perform., 2016, 25(11), p 4637-4648

P. Xue, B. Xiao and Z. Ma, Microstructure and Mechanical Properties of Friction Stir Welded Dissimilar Al-Cu Thin Plate Joints, in 10th International Symposium on Friction Stir Welding (Beijing, 2014)

A. Esmaeili, M.K.B. Givi, and H.R.Z. Rajani, Investigation of Weld Defects in Dissimilar Friction stir Welding of Aluminium to Brass by Radiography, Sci. Technol. Weld. Join., 2013, 17(7), p 539-543

A. Esmaeili, H.R. Zareie Rajani, M. Sharbati, M.K.B. Givi, and M. Shamanian, The Role of Rotation Speed on Intermetallic Compounds Formation and Mechanical Behavior of Friction Stir Welded Brass/Aluminum 1050 Couple, Intermetallics, 2011, 19(11), p 1711-1719

A. Esmaeili, M.K.B. Givi, and H.R.Z. Rajani, A Metallurgical and Mechanical Study on Dissimilar Friction Stir welding of Aluminum 1050 to Brass (CuZn30), Mater. Sci. Eng. A, 2011, 528(22-23), p 7093-7102

L. Qiao, H.H. Yang, and J.F. Sheng, Comparison Study on Friction-Welded Cu-Al Material and Pure Cu/Al, Mater. Sci. Forum, 2015, 817, p 374-378

M.F.X. Muthu and V. Jayabalan, Tool Travel Speed Effects on the Microstructure of Friction Stir Welded Aluminum-Copper Joints, J. Mater. Process. Technol., 2015, 217, p 105-113

D. Yaduwanshi, S. Pal, and S. Bag, Effect of Preheating on Mechanical Properties of Hybrid Friction Stir Welded Dissimilar Joint, in 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR) (Assam, 2014)

R. Sarrafi, A.H. Kokabi, M.A. Gharacheh, and B. Shalchi, Evaluation of Microstructure and Mechanical Properties of Aluminum to Copper Friction Stir Butt Welds, Frict. Stir Weld. Process., 2011, VI, p 253-264

M. Girard, B. Huneau, C. Genevois, X. Sauvage, and G. Racineux, Friction Stir Diffusion Bonding of Dissimilar Metals, Sci. Technol. Weld. Join., 2013, 15(8), p 661-665

W.-B. Lee, K.-S. Bang, and S.-B. Jung, Effects of Intermetallic Compound on the Electrical and Mechanical Properties of Friction Welded Cu/Al Bimetallic Joints During Annealing, J. Alloys Compd., 2005, 390(1-2), p 212-219

P. Eslami and A.K. Taheri, An Investigation on Diffusion Bonding of Aluminum to Copper Using Equal Channel Angular Extrusion Process, Mater. Lett., 2011, 65(12), p 1862-1864

Z. Huiwen, C. Wei, H. Jingshan, Y. Jiuchun, and Y. Shiqin, Formation and Evolution of Intermetallic Compounds at Interfaces of Cu/Al Joints by Ultrasonic-Assisted Soldering, J. Mater. Process. Technol., 2015, 223, p 1-7

Y. Xiao, H. Ji, M. Li, and J. Kim, Ultrasound-Assisted Brazing of Cu/Al Dissimilar Metals Using a Zn-3Al Filler Metal, Mater. Des., 2013, 52, p 740-747

Z. Ni, H. Zhao, P. Mi, and F. Ye, Microstructure and Mechanical Performances of Ultrasonic Spot Welded Al/Cu Joints with Al 2219 Alloy Particle Interlayer, Mater. Des., 2016, 92, p 779-786

J. Feng, X. Songbai, and D. Wei, Reliability Studies of Cu/Al Joints Brazed with Zn-Al-Ce Filler Metals, Mater. Des., 2012, 42, p 156-163

T. Solchenbach, P. Plapper, and W. Cai, Electrical Performance of Laser Braze-Welded Aluminum-Copper Interconnects, J. Manuf. Process., 2014, 16(2), p 183-189

T. Solchenbach and P. Plapper, Mechanical Characteristics of Laser Braze-welded Aluminium-Copper Connections, Opt. Laser Technol., 2013, 54, p 249-256

I. Bhamji, R.J. Moat, M. Preuss, P.L. Threadgill, A.C. Addison, and M.J. Peel, Linear Friction Welding of Aluminium to Copper, Sci. Technol. Weld. Join., 2013, 17(4), p 314-320

Acknowledgment

This research was supported by the National Natural Science Foundation of China (No. 51761145108).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, SL., Li, CX., Wei, YK. et al. Novel Method of Aluminum to Copper Bonding by Cold Spray. J Therm Spray Tech 27, 624–640 (2018). https://doi.org/10.1007/s11666-018-0707-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0707-1