Abstract

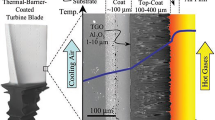

This research proposes a simple yet highly sensitive method based on electrical resonance of an eddy-current probe to detect delamination of thermal barrier coating (TBC). This method can directly measure the mechanical characteristics of TBC compared to conventional ultrasonic testing and infrared thermography methods. The electrical resonance-based method can detect the delamination of TBC from the metallic bond coat by shifting the electrical impedance of eddy current testing (ECT) probe coupling with degraded TBC, and, due to this shift, the resonant frequencies near the peak impedance of ECT probe revealed high sensitivity to the delamination. In order to verify the performance of the proposed method, a simple experiment is performed with degraded TBC specimens by thermal cyclic exposure. Consequently, the delamination with growth of thermally grown oxide in a TBC system is experimentally identified. Additionally, the results are in good agreement with the results obtained from ultrasonic C-scanning.

Similar content being viewed by others

References

R.A. Miller, History of Thermal Barrier Coatings for Gas Turbine Engines: Emphasizing NASA’s Role from 1942 to 1990, NASA Technical Memorandum, NASA/TM-2009-215459, 2009

A.G.E.A. Rabiei and A.G. Evans, Failure Mechanisms Associated with the Thermally Grown Oxide in Plasma-Sprayed Thermal Barrier Coatings, Acta Mater., 2000, 48(15), p 3963-3976

H. Dong, G.J. Yang, C.X. Li, X.T. Luo, and C.J. Li, Effect of TGO Thickness on Thermal Cyclic Lifetime and Failure Mode of Plasma-Sprayed TBCs, J. Am. Ceram. Soc., 2014, 97(4), p 1226-1232

T. Kang, J. Zhang, M. Yuan, S.J. Song, H.J. Kim, Y. Kim, and C.S. Seok, Influence of Compressive Stress in TGO Layer on Impedance Spectroscopy from TBC Coatings, J. Korean Soc. Nondestr. Test., 2013, 33(1), p 46-53 (in Korean)

H. Brodin, M. Jinnestrand, S. Johansson, and S. Sjostrom, Thermal Barrier Coating Fatigue Life Assessment, Technical Report, Siemens AG, 2006

Z. Ma, Y. Zhao, Z. Luo, and L. Lin, Ultrasonic Characterization of Thermally Grown Oxide in Thermal Barrier Coating by Reflection Coefficient Amplitude Spectrum, Ultrasonics, 2014, 54(4), p 1005-1009

Y. Zhao, L. Lin, X.M. Li, and M.K. Lei, Simultaneous Determination of the Coating Thickness and Its Longitudinal Velocity by Ultrasonic Nondestructive Method, NDT E Int., 2010, 43(7), p 579-585

H.P. Crutzen, F. Lakestani, and J.R. Nicholls, Ultrasonic Characterisation of Thermal Barrier Coatings in Proceedings of Ultrasonics Symposium, 1996. 1996 IEEE (vol 1, p 731-734). IEEE (1996)

H.L.R. Chen, B. Zhang, M.A. Alvin, and Y. Lin, Ultrasonic Detection of Delamination and Material Characterization of Thermal Barrier Coatings, J. Therm. Spray Technol., 2012, 21(6), p 1184-1194

B. Zhang, Nondestructive Evaluation of Thermal Barrier Coating Systems Using Ultrasonic Techniques, West Virginia University, 2010

J.I. Eldridge, T.J. Bencic, S.W. Allison, and D.L. Beshears, Depth-Penetrating Temperature Measurements of Thermal Barrier Coatings Incorporating Thermographic Phosphors, J. Therm. Spray Technol., 2004, 13(1), p 44-50

G. Ptaszek, P. Cawley, D. Almond, and S. Pickering, Transient Thermography Testing of Unpainted Thermal Barrier Coating (TBC) Systems, NDT E Int., 2013, 59, p 48-56

R. Hughes, Y. Fan, and S. Dixon, Near Electrical Resonance Signal Enhancement (NERSE) in Eddy-Current Crack Detection, NDT E Int., 2014, 66, p 82-89

L. Yong, Z. Chen, Y. Mao, and Q. Yong, Quantitative Evaluation of Thermal Barrier Coating Based on Eddy Current Technique, NDT E Int., 2012, 50, p 29-35

J.M. Kim, S.G. Lee, H.J. Kim, S.J. Song, C.S. Seok, and Y.Z. Lee, Designing a Highly Sensitive Eddy Current Sensor for Evaluating Damage on Thermal Barrier Coating, J. Korean Soc. Nondestr. Test., 2016, 36(3), p 202-210 (in Korean)

Acknowledgments

This work was supported by the Basic Science Research Program provided by National Research Foundation of Korea (NRF), funded by the Ministry of Science, and ICT and Future Planning (Grant No. 2011-0020024).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J.M., Park, JH., Lee, H.G. et al. An Effective Electrical Resonance-Based Method to Detect Delamination in Thermal Barrier Coating. J Therm Spray Tech 27, 336–343 (2018). https://doi.org/10.1007/s11666-017-0670-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0670-2