Abstract

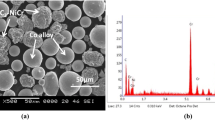

Highly corrosion- and wear-resistant thermally sprayed chromium carbide (Cr3C2)-based cermet coatings are nowadays a potential highly durable solution to allow traditional fluidized bed combustors (FBC) to be operated with ecological waste and biomass fuels. However, the heat input of thermal spray causes carbide dissolution in the metal binder. This results in the formation of carbon saturated metastable phases, which can affect the behavior of the materials during exposure. This study analyses the effect of carbide dissolution in the metal matrix of Cr3C2-50NiCrMoNb coatings and its effect on chlorine-induced high-temperature corrosion. Four coatings were thermally sprayed with HVAF and HVOF techniques in order to obtain microstructures with increasing amount of carbide dissolution in the metal matrix. The coatings were heat-treated in an inert argon atmosphere to induce secondary carbide precipitation. As-sprayed and heat-treated self-standing coatings were covered with KCl, and their corrosion resistance was investigated with thermogravimetric analysis (TGA) and ordinary high-temperature corrosion test at 550 °C for 4 and 72 h, respectively. High carbon dissolution in the metal matrix appeared to be detrimental against chlorine-induced high-temperature corrosion. The microstructural changes induced by the heat treatment hindered the corrosion onset in the coatings.

Similar content being viewed by others

References

P. Lempp, Biomass Co-Firing, in Technology brief E21–January. International Energy Agency-Energy Technology Systems Analysis Programme (IEA-ETSAP), and International Renewable Energy Agency (IRENA) (2013)

J. Oh, M. McNallan, G. Lai, and M. Rothman, High Temperature Corrosion of Superalloys in an Environment Containing both Oxygen and Chlorine, Metall. Trans. A, 1986, 17(6), p 1087-1094

M. Spiegel, A. Zahs, and H. Grabke, Fundamental Aspects of Chlorine Induced Corrosion in Power Plants, Mater High Temp, 2003, 20(2), p 153-159

A. Zahs, M. Spiegel, and H.J. Grabke, Chloridation And oxidation of Iron, Chromium, Nickel and Their Alloys in Chloridizing and Oxidizing Atmospheres at 400-700 °C, Corros. Sci, 2000, 42(6), p 1093-1122

S. Cha and M. Spiegel, Local Reactions of KCl Particles with Iron, Nickel and Chromium Surfaces, Mater. Corros, 2006, 57(2), p 159-164

G.Y. Lai, Waste-to-Energy Boilers and Waste Incinerators, High-Temperature Corrosion and Materials Applications, ASM International, 2007, p 335-358

P. Vainikka, M. Nieminen, and K. Sipilä, Waste Firing in Large Combustion Plants, Waste to Energy Conversion Technology, N.B. Klinghoffer, and M.J. Castaldi, Eds., 2013, p 98-119

B. Rukes and R. Taud, Status and Perspectives of Fossil Power Generation, Energy, 2004, 29(12), p 1853-1874

P. Viklund, A. Hjörnhede, P. Henderson, A. Stålenheim, and R. Pettersson, Corrosion of Superheater Materials in a Waste-to-Energy Plant, Fuel Process Technol, 2013, 105, p 106-112

A. Phongphiphat, C. Ryu, Y.B. Yang, K.N. Finney, A. Leyland, V.N. Sharifi, and J. Swithenbank, Investigation Into High-Temperature Corrosion in a Large-Scale Municipal Waste-to-Energy Plant, Corros. Sci, 2010, 52(12), p 3861-3874

M. Oksa, S. Tuurna, and T. Varis, Increased Lifetime for Biomass and Waste to Energy Power Plant Boilers with HVOF Coatings: High Temperature Corrosion Testing Under Chlorine-Containing Molten Salt, J. Therm. Spray Technol, 2013, 22(5), p 783-796

M. Oksa, P. Auerkari, J. Salonen, and T. Varis, Nickel-Based HVOF Coatings Promoting High Temperature Corrosion Resistance of Biomass-Fired Power Plant Boilers, Fuel Process. Technol, 2014, 125, p 236-245

M. Oksa, “Nickel-and Iron-Based HVOF Thermal Spray Coatings for High Temperature Corrosion Protection in Biomass-Fired Power Plant Boilers,” Ph.D. Thesis, Aalto University, 2015

M. Uusitalo, P. Vuoristo, and T. Mäntylä, Elevated Temperature Erosion–Corrosion of Thermal Sprayed Coatings in Chlorine Containing Environments, Wear, 2002, 252(7), p 586-594

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings. John Wiley & Sons, 2008, p 571

S. Zimmermann, B. Gries, and B. Brüning, New Cermet Powders for HVOF Spraying with Improved Corrosion and Oxidation Resistance for Offshore, Mining and Power Generation Applications, Therm. Spray Bull, 2011, 4(2), p 94-100

N. Otsuka, Effects of Fuel Impurities on the Fireside Corrosion of Boiler Tubes in Advanced Power Generating Systems—A Thermodynamic Calculation of Deposit Chemistry, Corros. Sci, 2002, 44(2), p 265-283

U. Brill, J. Kloewer and D.C. Agarwal, Influence of Alloying Elements on the Chlorination Behavior of Nickel-and Iron-Based Alloys (1996)

L. Nylöf and E. Häggblom, Corrosion of Experimental Superheater Alloys in Waste Fuel Combustion (1997)

N. Otsuka, Chemistry and Melting Characteristics of Fireside Deposits Taken from Boiler Tubes in Waste Incinerators, Corros. Sci, 2011, 53(6), p 2269-2276

Y. Kawahara, High Temperature Corrosion Mechanisms and Effect of Alloying Elements for Materials Used in Waste Incineration Environment, Corros. Sci, 2002, 44(2), p 223-245

V. Matikainen, H. Koivuluoto and P. Vuoristo, Microstructural Characteristics of Different Cr3C2 Coating Compositions Sprayed with HVOF and HVAF Processes, Proceeding of the 28th International Conference on Surface Modification Technologies, T.S. Sudarshan, P. Vuoristo, and H. Koivuluoto, Eds., June 16–18 (Tampere, Finland), Valardocs, 2014

W. Zhou, K. Zhou, C. Deng, K. Zeng, and Y. Li, Hot Corrosion Behaviour of HVOF-Sprayed Cr3C2-NiCrMoNbAl Coating, Surf. Coat. Technol, 2017, 309, p 849-859

M. Uusitalo, R. Backman, L. Berger, P. Vuoristo, and T. Mäntylä, Oxidation Resistance of Carbides in Chlorine-Containing Atmospheres, High Temp. Mater. Process, 2002, 21(5), p 307-320

P. Vuoristo, Thermal Spray Coating Process, Compr. Mater. Process, S. Hashmi, Ed., Newnes, 2014, 4, p 229-276

J. Guilemany, J. Nutting, and N. Llorcalsern, Microstructural Examination of HVOF Chromium Carbide Coatings for High-Temperature Applications, J. Therm. Spray Technol, 1996, 5(4), p 483-489

S. Matthews, M. Hyland, and B. James, Long-Term Carbide Development in High-Velocity Oxygen Fuel/High-Velocity Air Fuel Cr3C2-NiCr Coatings Heat Treated at 900 °C, J. Therm. Spray Technol, 2004, 13(4), p 526-536

S. Matthews, B. James, and M. Hyland, High Temperature Erosion of Cr3C2-NiCr Thermal Spray Coatings—The Role of Phase Microstructure, Surf. Coat. Technol, 2009, 203(9), p 1144-1153

Y. Ding, T. Hussain, and D. McCartney, High-Temperature Oxidation of HVOF Thermally Sprayed Incur–Cr3C2 Coatings: Microstructure and Kinetics, J. Mater. Sci, 2015, 50(20), p 6808-6821

International Organization for Standardization. ISO 17224: corrosion of Metals and Alloys—Test Method for High Temperature Corrosion Testing of Metallic Materials by Application of a Deposit of Salt, Ash, Or Other Substances. First Edition 2015-04-15. ISO 17224:2015(E).

D. Fantozzi, V. Matikainen, M. Uusitalo, H. Koivuluoto, and P. Vuoristo, Chlorine-Induced High Temperature Corrosion of Inconel 625 Sprayed Coatings Deposited with Different Thermal Spray Techniques, Surf. Coat. Technol, 2017, 318, p 233-243

NACE MR0175/ISO 15156-1, Petroleum and Natural Gas Industries-Materials for use in H2S Containing Environments in Oil and Gas Production-Part 1: General Principles for Selection of Cracking-Resistant Materials (2001)

S. Matthews, M. Hyland, and B. James, Microhardness Variation in Relation to Carbide Development in Heat Treated Cr3C2-NiCr Thermal Spray Coatings, Acta Mater, 2003, 51(14), p 4267-4277

S. Matthews, B. James, and M. Hyland, The Role of Microstructure in the High Temperature Oxidation Mechanism of Cr3C2-NiCr Composite Coatings, Corros, Sci, 2009, 51(5), p 1172-1180

L.M. Berger, Application of Hardmetals as Thermal Spray Coatings, Int. J. Refract. Metals Hard Mater, 2015, 49, p 350-364

S. Matthews and L. Berger, Long-Term Compositional/Microstructural Development of Cr3C2-NiCr Coatings at 500, 700 and 900 °C, Int. J. Refract. Metals Hard Mater, 2016, 59, p 1-18

V. Matikainen, G. Bolelli, H. Koivuluoto, M. Honkanen, M. Vippola, L. Lusvarghi, and P. Vuoristo, A Study of Cr3C2-Based HVOF-and HVAF-Sprayed Coatings: Microstructure and Carbide Retention, J. Therm. Spray Technol, 2017, 26(6), p 1239-1256

K. Dobler, H. Kreye, and R. Schwetzke, Oxidation of Stainless Steel in the High Velocity Oxy-Fuel Process, J. Therm. Spray Technol, 2000, 9(3), p 407-413

M. Hocking, V. Vasantasree, and P. Sidky, Metallic and Ceramic Coatings: Production, High-Temperature Properties, and Applications, Longman Scientific & Technical, 1988, p 670

H. Nielsen, F. Frandsen, K. Dam-Johansen, and L. Baxter, The Implications of Chlorine-Associated Corrosion on the Operation of Biomass-Fired Boilers, Progress Energy Combust. Sci, 2000, 26(3), p 283-298

M. Uusitalo, P. Vuoristo, and T. Mäntylä, Chlorine Corrosion of Thermally Sprayed Coatings at Elevated Temperatures, Proceedings of the 7th Liege Conference on Materials for Advanced Power Engineering, J. Lecomte-Beckers, F. Schubert, P.J. Ennis, Eds., (Julich, Germany), Energy Technology Forschungszentrum Julich, 30, 2002

Acknowledgements

The work has been done within the DIMECC HYBRIDS (Hybrid Materials) program. We gratefully acknowledge the financial support from the Finnish Funding Agency for Innovation (Tekes) and the participating companies. A special thank goes also to Mr. Mikko Kylmälahti of Tampere University of Technology for spraying the HVOF and HVAF coatings, and Dr. Tech. Lucio Azzari and Dr. Tech. Matteo Maggioni for their support with the MatLab scripts.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2017 International Thermal Spray Conference, held June 7-9, 2017, in Düsseldorf, Germany, that has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Fantozzi, D., Matikainen, V., Uusitalo, M. et al. Effect of Carbide Dissolution on Chlorine Induced High Temperature Corrosion of HVOF and HVAF Sprayed Cr3C2-NiCrMoNb Coatings. J Therm Spray Tech 27, 220–231 (2018). https://doi.org/10.1007/s11666-017-0645-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0645-3