Abstract

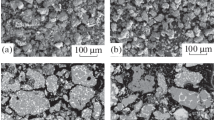

Nickel chromium-chromium carbide coatings provide good corrosion and wear resistance at high temperatures, making them ideal for applications where a harsh environment and high temperatures are expected. Thermal spray processes are preferred as deposition technique of cermets, but the high process temperatures can lead to decarburization and reduction of the coatings properties. Cold spray uses lower temperatures preventing decarburization. Since the metallic phase remains solid, the feedstock powder morphology becomes crucial on the deposition behavior. Six commercially available powders were studied, varying in morphology and metal/ceramic ratios. The powders were categorized into 4 groups depending on their morphology. Spherical powders lead to substrate erosion due to their limited overall ductility. Porous agglomerated and sintered powders lead to severely cracked coatings. For dense agglomerated and sintered powders, the outcome depended on the initial metal/ceramic ratio: powders with 25 wt.% NiCr led to substrate erosion while 35 wt.% NiCr powders led to dense coatings. Finally, blended ceramic-metal mixtures also lead to dense coatings. All coatings obtained had lower ceramic content than the initial feedstock powders. Interrupted spray tests, combined with FEA, helped drawing conclusions on the deposition behavior to explain the obtained results.

Similar content being viewed by others

References

J.A. Picas, M. Punset, S. Menargues, E. Martín, and M.T. Baile, Microstructural and Tribological Studies of as-Sprayed and Heat-Treated HVOF Cr3C2-CoNiCrAlY Coatings with a CoNiCrAlY Bond Coat, Surf. Coat. Technol., 2015, 268, p 317-324. doi:10.1016/j.surfcoat.2014.10.039

G.-C. Ji, C.-J. Li, Y.-Y. Wang, and W.-Y. Li, Microstructural Characterization and Abrasive Wear Performance of HVOF Sprayed Cr3C2-NiCr Coating, Surf. Coat. Technol., 2006, 200(24), p 6749-6757. doi:10.1016/j.surfcoat.2005.10.005

D. Poirier, J.-G.G. Legoux, and R.S. Lima, Engineering HVOF-Sprayed Cr3C2-NiCr Coatings: The Effect of Particle Morphology and Spraying Parameters on the Microstructure, Properties, and High Temperature Wear Performance, J. Therm. Spray Technol., 2013, 22(2-3), p 280-289. doi:10.1007/s11666-012-9833-3

E. Yun and S. Lee, Correlation of Microstructure with Hardness and Wear Resistance in Cr3C2/Stainless Steel Surface Composites Fabricated by High-Energy Electron Beam Irradiation, Mater. Sci. Eng., A, 2005, 405(1-2), p 163-172

L. Baiamonte, F. Marra, S. Gazzola, P. Giovanetto, C. Bartuli, T. Valente, and G. Pulci, Thermal Sprayed Coatings for Hot Corrosion Protection of Exhaust Valves in Naval Diesel Engines, Surf. Coat. Technol., 2015, doi:10.1016/j.surfcoat.2015.10.072

Y. Ding, T. Hussain, and D.G. McCartney, High-Temperature Oxidation of HVOF Thermally Sprayed NiCr-Cr3C2 Coatings: Microstructure and Kinetic, J. Mater. Sci., 2015, 50(20), p 6808-6821. doi:10.1007/s10853-015-9238-z

J.A. Picas, A. Forn, and G. Matthäus, HVOF Coatings as an Alternative to Hard Chrome for Pistons and Valves, Wear, 2006, 261(5-6), p 477-484. doi:10.1016/j.wear.2005.12.005

C.T. Kunioshi, O.V. Correa, and L.V. Ramanathan, High Temperature Oxidation and Erosion-Oxidation Behaviour of HVOF Sprayed Ni-20Cr, WC-20Cr-7Ni and Cr3C2-Ni-20Cr Coatings, Surf. Eng., 2006, 22(2), p 121-127. doi:10.1179/174329406X98403

B.Q. Wang and K. Luer, The Erosion-Oxidation Behavior of HVOF Cr3C2-NiCr Cermet Coating, Wear, 1994, 174(1), p 177-185

B.Q. Wang and Z.R. Shui, The Hot Erosion Behavior of HVOF Chromium Carbide-Metal Cermet Coatings Sprayed with Different Powders, Wear, 2002, 253(5), p 550-557

S. Matthews, Compositional Development as a Function of Spray Distance in Unshrouded/Shrouded Plasma-Sprayed Cr3C2-NiCr Coatings, J. Therm. Spray Technol., 2014, 24(3), p 515-533. doi:10.1007/s11666-014-0212-0

N. Matthews, R. Jones, and G.C. Sih, Application of Supersonic Particle Deposition to Enhance the Structural Integrity of Aircraft Structures, Sci. China Phys. Mech. Astron., 2013, 57(1), p 12-18. doi:10.1007/s11433-013-5367-z

J. Yuan, C. Ma, S. Yang, Z. Yu, and H. Li, Improving the Wear Resistance of HVOF Sprayed WC-Co Coatings by Adding Submicron-Sized WC Particles at the Splats’ Interfaces, Surf. Coat. Technol., 2015, doi:10.1016/j.surfcoat.2015.11.017

S.A. Alidokht, P. Manimunda, P. Vo, S. Yue, and R.R. Chromik, Cold Spray Deposition of a Ni-WC Composite Coating and Its Dry Sliding Wear Behavior, Surf. Coat. Technol., 2016, 308, p 424-434

J. Yuan, Q. Zhan, J. Huang, S. Ding, and H. Li, Decarburization Mechanisms of WC–Co during Thermal Spraying: Insights from Controlled Carbon Loss and Microstructure Characterization, Mater. Chem. Phys., 2013, 142(1), p 165-171

H. Myalska, G. Moskal, and K. Szymański, Microstructure and Properties of WC-Co Coatings, Modified by Sub-Microcrystalline Carbides, Obtained by Different Methods of High Velocity Spray Processes, Surf. Coat. Technol., 2014, 260, p 303-309. doi:10.1016/j.surfcoat.2014.07.097

R.C.C. Dykhuizen and M.F.F. Smith, Gas Dynamic Principles of Cold Spray, J. Therm. Spray Technol., 1998, 7(2), p 205-212

A.O. Tokarev, Structure of Aluminum Powder Coatings Prepared by Cold Gasdynamic Spraying, Met. Sci. Heat Treat., 1996, 38(3), p 136-139. doi:10.1007/BF01401446

A.P. Alkhimov, A.N. Papyrin, V.F. Kosarev, N.I. Nesterovich, and M.M. Shushpanov, Method and Device for Coating, European Patent 0484533 A4, 1992

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394. doi:10.1016/S1359-6454(03)00274-X

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5-6), p 794-808

M. Grujicic, J.R. Saylor, D.E. Beasley, W.S. DeRosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process, Appl. Surf. Sci., 2003, 219(3-4), p 211-227. doi:10.1016/S0169-4332(03)00643-3

T. Hussain, D.G. McCartney, P.H. Shipway, and D. Zhang, Bonding Mechanisms in Cold Spraying: The Contributions of Metallurgical and Mechanical Components, J. Therm. Spray Technol., 2009, 18(3), p 364-379

R.C.C. Dykhuizen, M.F.F. Smith, D.L.L. Gilmore, R.A.A. Neiser, X. Jiang, and S. Sampath, Impact of High Velocity Cold Spray Particles, J. Therm. Spray Technol., 1999, 8(4), p 559-564. doi:10.1361/105996399770350250

T. Samson, D. MacDonald, R. Fernández, and B. Jodoin, Effect of Pulsed Waterjet Surface Preparation on the Adhesion Strength of Cold Gas Dynamic Sprayed Aluminum Coatings, J. Therm. Spray Technol., 2015, 24(6), p 984-993. doi:10.1007/s11666-015-0261-z

E. Irissou, J.-G. Legoux, B. Arsenault, and C. Moreau, Investigation of Al-Al2O3 Cold Spray Coating Formation and Properties, J. Therm. Spray Technol., 2007, 16(5-6), p 661-668. doi:10.1007/s11666-007-9086-8

A. Sova, A. Papyrin, and I. Smurov, Influence of Ceramic Powder Size on Process of Cermet Coating Formation by Cold Spray, J. Therm. Spray Technol., 2009, 18(4), p 633-641. doi:10.1007/s11666-009-9359-5

Q. Wang, K. Spencer, N. Birbilis, and M.-X. Zhang, The Influence of Ceramic Particles on Bond Strength of Cold Spray Composite Coatings on AZ91 Alloy Substrate, Surf. Coat. Technol., 2010, 205(1), p 50-56. doi:10.1016/j.surfcoat.2010.06.008

A. Shkodkin, A. Kashirin, O. Klyuev, and T. Buzdygar, Metal Particle Deposition Stimulation by Surface Abrasive Treatment in Gas Dynamic Spraying, J. Therm. Spray Technol., 2006, 15(3), p 382-386

I. Finnie and D.H. McFadden, On the Velocity Dependence of the Erosion of Ductile Metals by Solid Particles at Low Angles of Incidence, Wear, 1978, 48(1), p 181-190. doi:10.1016/0043-1648(78)90147-3

A.S.M. Ang, C.C. Berndt, and P. Cheang, Deposition Effects of WC Particle Size on Cold Sprayed WC-Co Coatings, Surf. Coat. Technol., 2011, 205(10), p 3260-3267. doi:10.1016/j.surfcoat.2010.11.045

M. Jafari, M.H. Enayati, M. Salehi, S.M. Nahvi, S.N. Hosseini, and C.G. Park, Influence of Nickel-Coated Nanostructured WC-Co Powders on Microstructural and Tribological Properties of HVOF Coatings, J. Therm. Spray Technol., 2014, 23(8), p 1456-1469. doi:10.1007/s11666-014-0171-5

R. Lima, J. Karthikeyan, C. Kay, J. Lindemann, and C. Berndt, Microstructural Characteristics of Cold-Sprayed Nanostructured WC-Co Coatings, Thin Solid Films, 2002, 416(1-2), p 129-135. doi:10.1016/S0040-6090(02)00631-4

D.E. Wolfe, T.J. Eden, J.K. Potter, and A.P. Jaroh, Investigation and Characterization of Cr3C2-Based Wear-Resistant Coatings Applied by the Cold Spray Process, J. Therm. Spray Technol., 2006, 15(3), p 400-412. doi:10.1361/105996306X124400

H. Singh, T.S. Sidhu, J. Karthikeyan, and S.B.S. Kalsi, Development and Characterization of Cr3C2-NiCr Coated Superalloy by Novel Cold Spray Process, Mater. Manuf. Process., 2015, 2014, p 1-7. doi:10.1080/10426914.2014.973599

D. MacDonald, R. Fernández, F. Delloro, and B. Jodoin, Cold Spraying of Armstrong Process Titanium Powder for Additive Manufacturing, J. Therm. Spray Technol., 2016, doi:10.1007/s11666-016-0489-2

G.R. Johnson and W.H. Cook, A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures, in Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands (1983), pp. 541–547.

H.-J. Choi, M. Lee, and J.Y. Lee, Application of a Cold Spray Technique to the Fabrication of a Copper Canister for the Geological Disposal of CANDU Spent Fuels, Nucl. Eng. Des., 2010, 240(10), p 2714-2720. doi:10.1016/j.nucengdes.2010.06.038

S. Yin, Y. Xie, X. Suo, H. Liao, and X. Wang, Interfacial Bonding Features of Ni Coating on Al Substrate with Different Surface Pretreatments in Cold Spray, Mater. Lett., 2015, 138, p 143-147. doi:10.1016/j.matlet.2014.10.016

Y. Cormier, P. Dupuis, B. Jodoin, and A. Ghaei, Finite Element Analysis and Failure Mode Characterization of Pyramidal Fin Arrays Produced by Masked Cold Gas Dynamic Spray, J. Therm. Spray Technol., 2015, 24(8), p 1549-1565. doi:10.1007/s11666-015-0317-0

X. Wang, F. Feng, M.A. Klecka, M.D. Mordasky, J.K. Garofano, T. El-Wardany, A. Nardi, and V.K. Champagne, Characterization and Modeling of the Bonding Process in Cold Spray Additive Manufacturing, Addit. Manuf., 2015, 8, p 149-162. doi:10.1016/j.addma.2015.03.006

P.C. King, G. Bae, S.H. Zahiri, M. Jahedi, and C. Lee, An Experimental and Finite Element Study of Cold Spray Copper Impact onto Two Aluminum Substrates, J. Therm. Spray Technol., 2010, 19(3), p 620-634. doi:10.1007/s11666-009-9454-7

R. Ghelichi, S. Bagherifard, D. Macdonald, I. Fernandez-Pariente, B. Jodoin, and M. Guagliano, Experimental and Numerical Study of Residual Stress Evolution in Cold Spray Coating, Appl. Surf. Sci., 2014, 288, p 26-33. doi:10.1016/j.apsusc.2013.09.074

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkhimov, and V.M. Fomin, Cold Spray Technology (Elsevier, Amsterdam, 2006). https://books.google.cl/books?id=XjZMWNVvgLAC

C.-T. Fu and J.-M. Wu, Microstructure and Mechanical Properties of Cr3C2 Particulate Reinforced AI203 Matrix Composites, J. Mater. Sci., 1994, 29, p 2671-2677

J.M. Shockley, S. Descartes, P. Vo, E. Irissou, and R.R. Chromik, The Influence of Al2O3 Particle Morphology on the Coating Formation and Dry Sliding Wear Behavior of Cold Sprayed Al-Al2O3 Composites, Surf. Coat. Technol., 2015, 270, p 324-333. doi:10.1016/j.surfcoat.2015.01.057

A. Sova, V.F. Kosarev, A. Papyrin, and I. Smurov, Effect of Ceramic Particle Velocity on Cold Spray Deposition of Metal-Ceramic Coatings, J. Therm. Spray Technol., 2010, 20(1-2), p 285-291. doi:10.1007/s11666-010-9571-3

R.G. Maev and E. Leshchinsky, Low Pressure Gas Dynamic Spray: Shear Localization During Particle Shock Consolidation, Thermal Spray 2006: Science, Innovation and Application on CD-ROM, B. Marple, M. Hyland, Y.-C. Lau, R. Lima, and J. Voyer, Ed., May 15-18, 2006 (Seattle, WA), ASM International, 2006, 1480 p

H.A. Abdel-Aal, On the Influence of Thermal Properties on Wear Resistance of Rubbing Metals at Elevated Temperatures, J. Tribol. Am. Soc. Mech. Eng., 2000, 122(3), p 657. doi:10.1115/1.555417

D.R. Lide, CRC Handbook of Chemistry and Physics, 84th edn (Taylor & Francis, London, 2003). https://books.google.cl/books?id=kTnxSi2B2FcC

M. Bauccio, ASM Engineered Materials Reference Book (ASM International, Seattle, 1994). https://books.google.cl/books?id=f3xUAAAAMAAJ.

M.W.J. Chase, NIST-JANAF Thermochemical Tables (American Institute of Physics, College Park, 1998). https://books.google.cl/books?id=n5p9RAAACAAJ.

E. Uhlmann, M.G. von der Schulenburg, and R. Zettier, Finite Element Modeling and Cutting Simulation of Inconel 718, CIRP Ann. Manuf. Technol., 2007, 56(1), p 61-64

D. Steinberg, Equation of State and Strength Properties of Selected Materials (Lawrence Livermore National Laboratory, Livermore, 1996). https://books.google.cl/books?id=UyEXHAAACAAJ.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fernandez, R., Jodoin, B. Effect of Particle Morphology on Cold Spray Deposition of Chromium Carbide-Nickel Chromium Cermet Powders. J Therm Spray Tech 26, 1356–1380 (2017). https://doi.org/10.1007/s11666-017-0580-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0580-3