Abstract

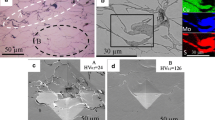

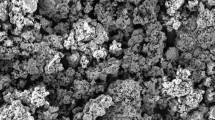

Cu and Cu-MoS2 coatings were fabricated by cold spray, and the fretting wear performance of the two coatings was compared. A mixture (95 wt.% Cu + 5 wt.% MoS2) was used as feedstock for the composite coating. Coatings were sprayed with identical gas flow conditions on the substrates pre-heated to approximately 170 °C. The morphology of coating top surface and polished cross sections was analyzed by scanning electron microscopy (SEM) and light optical microscopy (LOM). The influence of MoS2 on Cu deposition was examined. The local MoS2 concentration within the coating was found to affect the hardness. Fretting tests were carried out at two different normal loads, and the influence of MoS2 on friction and wear was studied. The morphology and elemental compositions of the wear scars and wear debris were observed by SEM and energy dispersive x-ray spectroscopy (EDS), respectively.

Similar content being viewed by others

References

A.R. Lansdown, Tribology Series, Elsevier, Amsterdam, 1999

J.K. Lancaster, Composite Self-lubricating Bearing Materials, Proc. Inst. Mech. Eng., 1967-1968, 182(2), p 33-54

C.H. Hager, Jr., et al., The Use of Nickel Graphite Composite Coatings for the Mitigation of Gross Slip Fretting Wear on Ti6Al4V Interfaces, Wear, 2009, 267, p 1470-1481

S. Dhanasekaran et al., Dry Sliding Friction and Wear Characteristics of Fe-C-Cu Alloy Containing Molybdenum Disulphide, Mater. Des., 2007, 28, p 1135-1141

H. Kato et al., Wear and Mechanical Properties of Sintered Copper-Tin Composites Containing Graphite or Molybdenum Disulfide, Wear, 2003, 255, p 573-578

H. Du et al., Structure, Mechanical and Sliding Wear Properties of WC-Co/MoS2-Ni Coatings by Detonation Gun Spray, Mater. Sci. Eng., A, 2007, 445-446, p 122-134

H. Du et al., Fabrication and Evaluation of D-Gun Sprayed WC-Co Coating with Self-lubricating Property, Tribol. Lett., 2006, 23, p 261-266

J. Yuan et al., Fabrication and Evaluation of Atmospheric Plasma Spraying WC-Co-Cu-MoS2 Composite Coatings, J. Alloys Compd., 2011, 509, p 2576-2581

A.M. Kovalchenko et al., The Tribological Properties and Mechanism of Wear of Cu-Based Sintered Powder Materials Containing Molybdenum Disulfide and Molybdenum Diselenite Under Unlubricated Sliding Against Copper, Wear, 2012, 290-291, p 106-123

A. Papyrin et al., Cold Spray Technology, Elsevier, Amsterdam, 2007

H. Assadi et al., Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

M. Yamada et al. Fabrication of Cu-MoS2 Composite Coating by Cold Spraying and Evaluation of Its Property, ITSC 2009: International Thermal Spray Conference, Las Vegas, 2009

I. Smid et al., Cold-Sprayed Ni-hBN Self-lubricating Coatings, Tribol. Trans., 2012, 55(5), p 599-605

G. Aggarwal, “Development of Self-lubricating Coatings via Cold Spray Process: Feedstock Formulation and Deformation Modeling,” Ph.D. dissertation, The Pennsylvania State University, 2007

A.R. Warmuth et al., The Effect of Contact Geometry on Fretting Wear Rates and Mechanisms for a High Strength Steel, Wear, 2013, 301, p 491-500

S. Fouvry et al., An Effective Friction Energy Density Approach to Predict Solid Lubricant Friction Endurance: Application to Fretting Wear, Wear, 2014, 319, p 211-226

S. Fouvry et al., Analysis of Sliding Behaviour for Fretting Loadings: Determination of Transition Criteria, Wear, 1995, 185, p 35-46

Z.R. Zhou et al., Nucleation and Early Growth of Tribologically Transformed Structure (TTS) Induced by Fretting, Wear, 1997, 212, p 50-58

R.R. Chromik et al., Materials Phenomena Revealed by In Situ Tribometry, JOM, 2012, 64(1), p 35-43

Y. Berthier et al., Velocity Accommodation in Fretting, Wear, 1988, 125, p 25-38

E. Sauger et al., Tribologically transformed structure in fretting, Wear, 2000, 245, p 39-52

O. Vingsbo et al., On fretting maps, Wear, 1988, 126, p 131-147

Y. Berthier et al., Fretting Fatigue and Fretting Wear, Tribol. Int., 1989, 22(4), p 235-242

L. Vincent et al., Mechanics and Materials in Fretting, Wear, 1992, 153, p 135-148

A. Savan et al., Modern Solid Lubrication: Recent Developments and Applications of MoS2, Lubr. Sci., 2000, 12(2), p 185-203

C. Mary et al., Pressure and Temperature Effects on Fretting Wear Damage of a Cu-Ni-In Plasma Coating Versus Ti17 Titanium Alloy Contact, Wear, 2011, 272, p 18-37

S.C. Lim et al., Wear-Mechanism Maps, Acta Metall., 1987, 35(1), p 1-24

Acknowledgments

The authors gratefully acknowledge the financial support from Natural Sciences and Engineering Research Council (NSERC) of Canada. They gratefully acknowledge help from Lisa Lee for data analysis, Walker Nickerson for sample preparation, Lionel Lafarge (INSA-Lyon) for the design of the fretting device, Edouard Régis (INSA-Lyon) for technical help, and Tekna Plasma Systems Inc. for donation of the powder. The authors acknowledge administrative support from Drs. Eric Irissou and Jean-Gabriel Legoux (the NRC) and Stephen Yue (McGill University) and technical support from Mr. Jean Francois Alarie at the McGill Aerospace Materials and Alloy Design Center (MAMADC) cold spray facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Descartes, S., Vo, P. et al. Cold-Sprayed Cu-MoS2 and Its Fretting Wear Behavior. J Therm Spray Tech 25, 473–482 (2016). https://doi.org/10.1007/s11666-015-0372-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0372-6