Abstract

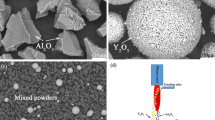

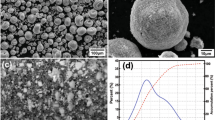

In the present study, the phase composition and generation mechanism of the nanocrystals located in the microcracks of plasma-sprayed Al2O3 coating were reevaluated. The Al2O3 coatings were investigated using transmission electron microscopy and x-ray diffraction. We supply the detailed explanations to support the new viewpoint that in situ formation of α-Al2O3 nanocrystals in the preexisting microcracks of the as-sprayed Al2O3 coating may be due to the stress-induced phase transformation. Owing to the partially coherent relationship, the phase interfaces between the α-Al2O3 nanocrystals with the preferred orientation and the γ-Al2O3 matrix may possess better bonding strength. The α-Al2O3 nanocrystals could repair the microcracks in the coating, which further strengthens grain boundaries. Grain boundary strengthening is beneficial to the coating fracture toughness enhancement.

Similar content being viewed by others

References

N.N. Ault, Characteristics of refractory oxide coatings produced by flame-spraying, J. Am. Ceram. Soc., 1957, 40(3), p 69-74

R. McPherson, Formation of metastable phase in flame-prepared and plasma-prepared alumina, J. Mater. Sci., 1973, 8(6), p 851-858

C.C. Stahr, S. Saaro, L.-M. Berger, J. Dubský, K. Neufuss, and M. Herrmann, Dependence of the stabilization of alpha-alumina on the spray process, J. Therm. Spray Technol., 2007, 16(5-6), p 822-830

Y. Lin, C. Wang, and J. Tao, Induction effect of alpha-Al2O3 seeds on formation of alumina coatings prepared by double glow plasma technique, Surf. Coat. Technol., 2013, 235, p 544-551

Z. Yin, S. Tao, X. Zhou, and C. Ding, Particle in-flight behavior and its influence on the microstructure and mechanical properties of plasma-sprayed Al2O3 coatings, J. Eur. Ceram. Soc., 2008, 28(6), p 1143-1148

G. Di Girolamo, A. Brentari, C. Blasi, and E. Serra, Microstructure and mechanical properties of plasma sprayed alumina-based coatings, Ceram. Int., 2014, 40(8), p 12861-12867

K. Yang, J. Feng, X. Zhou, and S. Tao, In-situ formed gamma-Al2O3 nanocrystals repaired and toughened Al2O3 coating prepared by plasma spraying, Surf. Coat. Technol., 2012, 206(13), p 3082-3087

K. Yang, X. Zhou, H. Zhao, and S. Tao, Microstructure and mechanical properties of Al2O3-Cr2O3 composite coatings produced by atmospheric plasma spraying, Surf. Coat. Technol., 2011, 206(6), p 1362-1371

K. Yang, J. Chen, F. Hao, C. Liu, S. Tao, and C. Ding, Stress-induced phase transformation and amorphous-to-nanocrystalline transition in plasma-sprayed Al2O3 coating with relative low temperature heat treatment, Surf. Coat. Technol., 2014, 253, p 277-283

A. Rico, C.J. Múnez, and J. Rodríguez, On the relevance of microstructure in the fracture toughness of nanostructured alumina-13% titania coatings, Surf. Coat. Technol., 2014, 243, p 46-50

J.-J. Kang, B.-S. Xu, H.-D. Wang, and C.-B. Wang, Influence of contact stress on rolling contact fatigue of composite ceramic coatings plasma sprayed on a steel roller, Tribol. Int., 2014, 73, p 47-56

S. Widjaja, A.M. Limarga, and T.H. Yip, Modeling of residual stresses in a plasma-sprayed zirconia/alumina functionally graded-thermal barrier coating, Thin Solid Films, 2003, 434(1-2), p 216-227

J. Pina, A. Dias, and J.L. Lebrun, Study by X-ray diffraction and mechanical analysis of the residual stress generation during thermal spraying, Mater. Sci. Eng., A, 2003, 347(1-2), p 21-31

X. Teng, H. Liu, and C. Huang, Effect of Al2O3 particle size on the mechanical properties of alumina-based ceramics, Mater. Sci. Eng., A, 2007, 452-453, p 545-551

A.P. Goswami, S. Roy, M.K. Mitra, and G.C. Das, Microstructure dependent hardness and fracture behavior in liquid-phase-sintered Al2O3, Ceram. Int., 2000, 26, p 397-410

V. Edlmayr, M. Moser, C. Walter, and C. Mitterer, Thermal stability of sputtered Al2O3 coatings, Surf. Coat. Technol., 2010, 204, p 1576-1581

J. Musil, J. Blazek, P. Zeman, S. Proksova, M. Sasek, and R. Cerstvy, Thermal stability of alumina thin films containing gamma-Al2O3 phase prepared by reactive magnetron sputtering, Appl. Surf. Sci., 2010, 257, p 1058-1062

Acknowledgments

The study is jointly supported by National Nature Science Foundation of China (51302299), Shanghai Nature Science Fund Project (13ZR1446000) and Youth Innovation Promotion Association, Chinese Academy of Sciences. Simultaneously, we are grateful to Inorganic Materials Analysis and Testing Center of Shanghai Institute of Ceramics for providing the support for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, K., Feng, J., Rong, J. et al. In situ Formed α-Al2O3 Nanocrystals Repaired the Preexisting Microcracks in Plasma-Sprayed Al2O3 Coating via Stress-Induced Phase Transformation. J Therm Spray Tech 25, 518–525 (2016). https://doi.org/10.1007/s11666-015-0367-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0367-3