Abstract

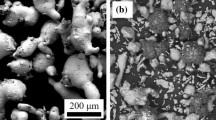

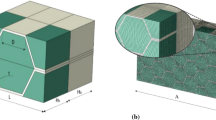

Abradable seals are used in aircraft engine compressor and turbine to decrease fuel consumption. Their role is to minimize the clearance between the rotating blades of an engine rotor and the casing to reduce air leakages (compressor) or air-fuel combustion product leakages (turbine). Operating temperatures in turbines (up to 1800 °C) can induce a thermal expansion of the blades and give rise to contacts providing damages to the blades or casing. Thus, in case of contact, the blade should remove the abradable seals applied to the casing without being damaged. Besides, the seal must be resistant to the turbine environment. Direct relationships have been observed between plasma spray operating parameters and abradable coating performances. The aim of this study is to determine those relationships for YSZ-Polyester abradable composite coatings. This study is conducted within the framework of the 7FP European project E-BREAK to reach the environmental objectives of the European Advisory Council for Aviation Research and innovation.

Similar content being viewed by others

References

European Commission, Acare Flightpath2050: Europe’s Vision for Aviation, Publications Office of the European Union, Luxembourg, 2011

T.N. Rhys-Jones, The Use of Thermally Sprayed Coatings for Compressor and Turbine Applications in Aero Engines, Surf. Coat. Technol., 1990, 42(1), p 1-11

USA-Dept-of-Transportation, Airplane Flying Handbook: Federal Aviation Administration, Skyhorse Publishing, New York, 2007

S. Karthikeyan, V. Balasubramanian, and R. Rajendran, Developing Empirical Relationships to Estimate Porosity and Young’s Modulus of Plasma Sprayed Ysz Coatings, Appl. Surf. Sci., 2014, 296, p 31-46

Z. Wang, A. Kulkarni, S. Deshpande, T. Nakamura, and H. Herman, Effects of Pores and Interfaces on Effective Properties of Plasma Sprayed Zirconia Coatings, Acta Mater., 2003, 51(18), p 5319-5334

M. Friis, C. Persson, and J. Wigren, Influence of Particle In-Flight Characteristics on the Microstructure of Atmospheric Plasma Sprayed Yttria Stabilized Zro2, Surf. Coat. Technol., 2001, 141(2-3), p 115-127

R.K. Schmid, New High Temperature Abradables for Gas Turbines, Degree of Technical Sciences, Swiss Federal Institute of Technology, Zurich, 1997

D. Sporer, M. Dorfman, L. Xie, A. Refke, I. Giovannetti, and M. Giannozzi, Processing and Properties of Advanced Ceramic Abradable Coatings, Thermal Spray 2007: Global Coating Solutions, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R. S. Lima, and G. Montavon, May 14-16, (Ohio), ASM International, 2007, p 495-500

J.F. Bisson, C. Moreau, M. Dorfman, C. Dambra, and J. Mallon, Influence of Hydrogen on the Microstructure of Plasma-Sprayed Yttria-Stabilized Zirconia Coatings, J. Therm. Spray Technol., 2005, 14(1), p 85-90

B.R. Marple, R.S. Lima, C. Moreau, S.E. Kruger, L. Xie, and M.R. Dorfman, Yttria-Stabilized Zirconia Thermal Barriers Sprayed Using N[2]-H[2] and Ar-H[2] Plasmas: Influence of Processing and Heat Treatment on Coating Properties, J. Therm. Spray Technol., 2007, 16(5-6), p 791-797

P. Fauchais and M. Vardelle, Plasma Spraying: Present and Future, Pure Appl. Chem., 2009, 66(6), p 1247-1258

A. Vaidya, V. Srinivasan, T. Streibl, M. Friis, W. Chi, and S. Sampath, Process Maps for Plasma Spraying of Yttria-Stabilized Zirconia: An Integrated Approach to Design, Optimization and Reliability, Mater. Sci. Eng. A, 2008, 497(1-2), p 239-253

D.G. Puerta, Accepted Practices of Thermal Spray Technology: The Preparation and Evaluation of Thermal Spray Coatings: Mounting, J. Therm. Spray Technol., 2005, 14(4), p 450-452

D.G. Puerta, Accepted Practices of Thermal Spray Technology: The Preparation and Evaluation of Thermal Spray Coatings: Grinding, J. Therm. Spray Technol., 2006, 15(1), p 31-32

D.G. Puerta and G. Blann, Accepted Practices of Thermal Spray Technology: The Preparation and Evaluation of Thermal Spray Coatings: Fine Grinding & Polishing, J. Therm. Spray Technol., 2006, 15(2), p 174-176

J.P. Sauer, Accepted Practices of Thermal Spray Technology: Metallographic Preparation and Testing of Thermal Spray Coatings: Sectioning, J. Therm. Spray Technol., 2005, 14(3), p 313-314

J.C. Russ and R.T. Dehoff, Practical Stereology, Plenum Press, New York, 1999

Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials, ASTM E18-05e1, 2005

G. Antou, Amélioration De Revêtements Barrières Thermiques Par Un Procédé De Refusion Laser in Situ Utilisant Un Laser À Diodes, (Improvement of Thermal Barrier Coatings in Situ by a Laser Reflow Process Using a Diode Laser), Thèses De Troisème Cycle, Université Louis Pasteur, Strasbourg, 2004 (in French)

F.M. White, Heat and Mass Transfer, Addison-Wesley, Reading, 1988

R. Bassani and B. Piccigallo, Hydrostatic Lubrication, Elsevier Science, New York, 1992

P. Coussot, Rhéophysique La Matière Dans Tous Ses Etats, EDP Sciences, Les Ulis, 2012

P. Fauchais, M. Fukumoto, A. Vardelle, and M. Vardelle, Knowledge Concerning Splat Formation: An Invited Review, J. Therm. Spray Technol., 2004, 13(3), p 337-360

F. Peyraut, J.-L. Seichepine, H.I. Faraoun, C. Coddet, and M. Hertter, Numerical Simulation of the Hr15y Hardness Test of Abradable Thermally Sprayed Coatings, 2006, p 1027-1031

M. Yi, J. He, B. Huang, and H. Zhou, Friction and Wear Behaviour and Abradability of Abradable Seal Coating, Wear, 1999, 231(1), p 47-53

M. Vardelle and P. Fauchais, Plasma Spray Processes: Diagnostic and Control, Pure Appl. Chem., 1999, 71(10), p 1909-1918

S. Guessasma, G. Montavon, and C. Coddet, Velocity and Temperature Distributions of Alumina-Titania in-Flight Particles in the Atmospheric Plasma Spray Process, Surf. Coat. Technol., 2005, 192, p 70-76

M. Prystay, P. Gougeon, and C. Moreau, Structure of Plasma-Sprayed Zirconia Coatings Tailored by Controlling the Temperature and Velocity of the Sprayed Particles, J. Therm. Spray Technol., 2001, 10(1), p 67-75

P. Nylen, J. Wigren, J. Idetjärn, L. Pejryd, On-Line Microstructure and Property Control of Thermal Sprayed Abrasive Coatings, 2001, p 1213-1220

D.J. Varacalle, Jr., H. Herman, G.A. Bancke, and W.L. Riggs, Ii, Vacuum Plasma Sprayed Alumina—Titania Coatings, Surf. Coat. Technol., 1992, 54-55(1), p 19-24

S. Gowri and G. Uma, Shankar, K. Narayanasamy, R. Krishnamurthy, Expert System for Process Optimization of Atmospheric Plasma Spraying of High Performance Ceramics, J. Mater. Process. Technol., 1997, 63(1-3), p 724-732

R. McPherson and P. Cheang, Eleatic Anisotropy of APS Alumina Coatings and Its Relationship to Microstructure, High Performance Ceramic Films and Coatings: Proceedings of the Satellite Symposium 1 on High Performance Ceramic Films and Coatings of the 7th International Meeting on Modern Ceramics Technologies (7th Cimtec-World Ceramics Congress), 1st ed., P. Vincenzini, (Montecatini Terme), Elsevier, 1991

J.S. Wallace and J. Ilavsky, Elastic Modulus Measurements in Plasma Sprayed Deposits, J. Therm. Spray Technol., 1998, 7(4), p 521-526

C.J. Li and A. Ohmori, Relationships between the Microstructure and Properties of Thermally Sprayed Deposits, J. Therm. Spray Technol., 2002, 11(3), p 365-374

D.R. Mash, N.E. Weare, and D.L. Walker, Process Variables in Plasma-Jet Spraying, J. Met., 1961, 13, p 473-478

T. Steeper, A. Rotolico, J. Nerz, and W. Riggs, Optimizing Plasma-Sprayed Alumina Titania Coatings Using Statistical Methods, 1993, p 37-48

P. Fauchais, M. Vardelle, A. Vardelle, and J.F. Coudert, Plasma Spraying of Ceramic Particles in Argon-Hydrogen D.C. Plasma Jets: Modeling and Measurements of Particles in Flight Correlation with Thermophysical Properties of Sprayed Layers, Metall. Mater. Trans. B, 1989, 20(2), p 263-276

M. Mellali, Influence De La Rugosité Et De La Température De Surface Du Substrat Sur L’adhérence/Cohésion Et Sur Les Contraintes Résiduelles Au Sein De Dépôts D’alumine Projetés Par Plasma (Influence of the Roughness and Temperature of the Substrate Surface on Adhesion and Residual Stresses in Alumina Coatings Manufactured by Plasma Spraying), Ph.D. thesis, University of Limoges, Limoges, 1994 (in French)

Acknowledgments

The research is funded by the European Union Seventh Framework Program 2007-2013, under Grant agreement No. 314366.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aussavy, D., Bolot, R., Montavon, G. et al. YSZ-Polyester Abradable Coatings Manufactured by APS. J Therm Spray Tech 25, 252–263 (2016). https://doi.org/10.1007/s11666-015-0358-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0358-4