Abstract

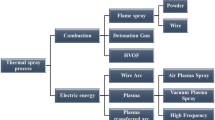

The components in an integrated steel plant are invariably exposed to harsh working environments involving exposure to high temperatures, corrosive gases, and erosion/wear conditions. One such critical component in the blast furnace is the tuyere, which is prone to thermal damage by splashing of molten metal/slag, erosive damage by falling burden material, and corrosion from the ensuing gases. All the above, collectively or independently, accelerate tuyere failure, which presents a potential explosion hazard in a blast furnace. Recently, thermal spray coatings have emerged as an effective solution to mitigate such severe operational challenges. In the present work, five different coatings deposited using detonation spray and air plasma spray techniques were comprehensively characterized. Performance evaluation involving thermal cycling, hot corrosion, and erosion tests was also carried out. Based on the studies, a coating system was suggested for possible tuyere applications and found to yield substantial improvement in service life during actual field trials.

Similar content being viewed by others

References

C. Copeland and S. Street, A Practical Engineering Approach to Improving the Reliability of Blast Furnace Tuyeres, Iron Steel Technol., 2013, p 47-62

S. Matthews and B. James, Review of Thermal Spray Coating Applications in the Steel Industry: Part-1 Hardware in Steel Making to the Continuous Annealing Process, J. Therm. Spray Technol., 2010, 19(6), p 1267-1276

J. Hartman, Notes on Tuyeres in the Iron Blast Furnace, Trans. Am. Inst. Min. Eng., 1898, 28, p 666-673

T. Shellhammer and R. Walsh, High Conductivity Copper in the Blast Furnace, AISTech Conference Proceedings, 2010, I, p 437-452

Anon., The Explosion of No. 5 Blast Furnace, Corus UK Ltd., Port Talbot, United Kingdom, Health and Safety Executive Report, Uk, 2001, p 47

Y. Zhao, M. Atkinson, H. Crosman, C. Tetrault, D. Roldan, and C. Zhou, Investigation of Tuyere Nose Failures at U. S. Steel—Great Lakes Works B2 Blast Furnace, AISTech Conference Proceedings, 2005, I, p 491-496

H. Nakahira, Blast-Furnace Tuyere Having Excellent Thermal Shock Resistance and High Durability, US3977660 A, 1976

H. Watanabe, S. Shoji, A. Sato, and T. Oka, Blast-Furnace Tuyere, US4189130 A, 1980

H. Fukubayashi, Metal-Zirconia Composite Coating, International Patent, Publication Number WO 02/075004 A1. Praxair S.T. Technology Ltd., 2002

D. Yang, Y. Guan, Y. Zhang, J. Li, J. Hu, and W. Li, Application of Ceramic Coat Synthesized by In-Situ Combustion to BF Tuyere, J. Iron Steel Res. Int., 2007, 14(2), p 70-72

Y. Ohmae, Surface Coated Blast Furnace Tuyere Made of Copper or Copper Alloy and Method of Surface Coating the Same, US4139673, 1979

H. Yamaoka, M. Kawasaki, H. Kawanami, T. Shiino, and J. Yamashita, Tuyers for a Blast Furnace, US4043542, 1977

J. Song, T. Wang, J. Yuan, L. Zhang, and X. Tan, Tuyeres of Blast Furnace Surface Recombination Coating and Method for Preparing the Same, Publication Number CN101492749 (A). Baoshan Iron and Steel (CN), 2009

G. Sundararajan, D. Srinivasa Rao, G. Sivakumar, and S.V. Joshi, in Detonation Spray Coatings, ed. by J. Wang, W. Chung. Encyclopedia of Tribology, 1st ed. (Springer, US, 2013), p 736-742

E. Withey, C. Peorak, R. Trice, G. Dickinson, and T. Taylor, Design of 7 wt% Y2O3-ZrO2/Mullite Plasma Sprayed Composite Coatings for Increased Creep Resistance, J. Eur. Ceram. Soc., 2007, 27, p 4675-4683

M.M. Hossen, F.U.Z. Chowdhury, M.A. Gafur, A.K.M. Abdul Hakim, and S. Nasrin, Investigation of Mechanical Properties of Al2O3-20 wt % ZrO2 Composites as a Function of Sintering Temperature, Eur. Sci. J., 2014, 10(9), p 399-411

H. Tahara, M. Moriyama, and K. Fujiuchi, Ceramic Spraying Using Electromagnetically Accelerated Plasma, Proceedings of International Thermal Spray Conference, Osaka, Japan, 2004, p 612-618

N.L. Parthasarathi and M. Duraiselvam, Improvement of High Temperature Wear Resistance of AISI, 316 ASS Through NiCrBSiCFe Plasma Spray Coating, J. Min. Mater. Charact. Eng., 2010, 9(7), p 653-670

M.W. Richert, M. Książek, P. Pałka, S. Wawrzyniak, R. Grzelka, and K. Płońska-Niżnik, Microstructure Characterization of Chromium Carbide Coatings Deposited by Thermal Spray Processes, J. Achiev. Mater. Manufac. Eng., 2012, 55(1), p 108-112

L. Pawlowski, Properties of Coatings, The Science and Engineering of Coatings, 2nd ed. (John Wiley & Sons Ltd, 2008), p 399-400

A.A. Abdel-Samad, A.M.M. El-Bahloul, E. Lugscheider, and S.A. Rassoul, A Comparative Study on Thermally Sprayed Alumina Based Ceramic Coatings, J. Mater. Sci., 2000, 35(12), p 3127-3130

N. Margadant, S. Siegmann, J. Patscheider, T. Keller, W. Wagner, J. Ilavsky, J. Pisacka, G. Barbezat, P. Fiala, and T. Pirling, Microstructure—Property Relationships and Cross-Property-Correlations of Thermal Sprayed Ni-Alloy Coatings, Proceedings of Thermal Spray 2001—New Surfaces for New Millennium, Singapore, 2001, p 643-652

G. Sundararajan, D. Sen, and G. Sivakumar, The Tribological Behavior of Detonation Sprayed Coatings: The Importance of Coating Process Parameters, Wear, 2005, 258(1), p 377-391

W. Tie-Gang, Z. Sheng-Sheng, H. Wei-Gang, L. Jia-Bao, G. Jun, and S. Chao, Estimation of Residual Stress and Its Effects on the Mechanical Properties of Detonation Gun Sprayed WC-Co Coatings, Mater. Sci. Eng. A, 2010, 527(3), p 454-461

B. Rajasekaran, S. Sundara Raman Ganesh, V. Joshi, and G. Sundarajan, Performance of Plasma Sprayed and Detonation Gun Sprayed Cu-Ni-ln Coatings on Ti-6Al-4V Under Plain Fatigue and Fretting Fatigue Loading, Mater. Sci. Eng. A, 2008, 479(1-2), p 83-92

J.K.N. Murthy and B. Venkataraman, Abrasive Wear Behavior of WC-CoCr and Cr3C2-20(NiCr) Deposited by HVOF and Detonation Spray Processes, Surf. Coat. Technol., 2006, 200(8), p 2642-2652

G. Sivakumar, L. Ramakrishna, V. Jain, D. Srinivasa Rao, and G. Sundararajan, The Influence of the Process Parameters on the Properties of Detonation Sprayed WC-12Co Coatings, Proceedings of International Thermal Spray Conference. ASM Materials, 2001, p 1031-1038

D. Toma, W. Brandl, and G. Marginean, Wear and Corrosion Behaviour of Thermally Sprayed Cermet Coatings, Surf. Coat. Technol., 2001, 138(2-3), p 149-158

N.J. Claussen, Fracture Toughness of Al2O3 with an Unstable ZrO2 Dispersed Second Phase, J. Am. Ceram. Soc., 1976, 61, p 49-51

J. Wang and R. Stevens, Review Zirconia-Toughened Alumina (ZTA) Ceramics, J. Mater. Sci., 1989, 24, p 3421-3440

J.R. Davis, Ed., Handbook of Thermal Spray Technology (ASM International, Materials Park, OH, 2004), p 158

W.D. Callister Jr., Structure and Properties of Ceramics, Materials Science and Engineering: An Introduction, 6th ed. (John Wiley & Sons Ltd, 2009), p 399–400

Lidija. Ćurković, Ivan. Kumić, and Krešimir. Grilec, Solid Particle Erosion Behaviour of High Purity Alumina Ceramics, Ceram. Int., 2011, 37(1), p 29-35

W. Gao and Z. Li, Eds., Developments in High-Temperature Corrosion and Protection of Materials (Woodhead Publishing-CRC press, Cornwall, England), p 499

C. Ramachandra, K.N. Lee, and S.N. Tewari, Durability of TBCs with a Surface Environmental Barrier Layer Under Thermal Cycling in Air and in Molten Salt, Surf. Coat. Technol., 2003, 172, p 150-157

A. Keyvani, M. Saremi, and M.H. Sohi, Microstructural Stability of Zirconia-Alumina Composite Coatings During Hot Corrosion Test at 1050°C, J. Alloys Compd., 2009, 506(1), p 103-108

S. Sen, O. Ozdemir, A.S. Demirkıran, and U. Sen, Oxidation Kinetics of Chromium Carbide Coating Produced on AISI, 1040 Steel by Thermo-Reactive Deposition Method during High Temperature in Air, Adv. Mater. Res., 2012, 445, p 649-654

K.N. Lee, R.A. Miller, and N.S. Jacobson, New Generation of Plasma-Sprayed Mullite Coatings on Silicon Carbide, J. Am. Ceram. Soc., 1995, 78(3), p 705-710

S. Kamal, R. Jayaganthan, and S. Prakash, High Temperature Oxidation Studies of Detonation-Gun-Sprayed Cr3C2-NiCr Coating on Fe- and Ni-Based Superalloys in Air Under Cyclic Condition at 900°C, J. Alloys Compd., 2009, 472, p 378-389

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pathak, A., Sivakumar, G., Prusty, D. et al. Thermal Spray Coatings for Blast Furnace Tuyere Application. J Therm Spray Tech 24, 1429–1440 (2015). https://doi.org/10.1007/s11666-015-0350-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0350-z