Abstract

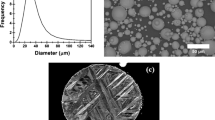

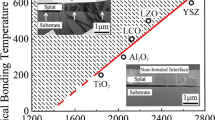

In this work, yttria-stabilized zirconia splats deposited onto different bond coatings were characterized. The influence of both substrate topography and temperature on splat morphologies was investigated. The substrate surface was described using a method characterized by multi-level roughness. On non-heated substrate, the peak-valley structure in scale of micrometer contributed to the formation of crater-like holes on splats. The amount of such holes was reduced with the increase of substrate temperature. It was also observed that on micro-smooth surface, island-like fragments in the center of splat would warp and their edges could be detached from the underlying substrate, especially when the substrate was heated. The obtained results reveal that the influence of substrate pre-heating on the splat formation is realized via thinning the air film near substrate surface.

Similar content being viewed by others

References

N.P. Padture, M. Gell, and E.H. Jordan, Materials Science—Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296(5566), p 280-284

Y. Wang, S. Jiang, M.D. Wang, S.H. Wang, T.D. Xiao, and P.R. Strutt, Abrasive Wear Characteristics of Plasma Sprayed Nanostructured Alumina/Titania Coatings, Wear, 2000, 237(2), p 176-185

S.R. Paital and N.B. Dahotre, Calcium Phosphate Coatings for Bio-implant Applications: Materials, Performance Factors, and Methodologies, Mater. Sci. Eng. R, 2009, 66(1-3), p 1-70

P. Fauchais, Understanding Plasma Spraying, J. Phys. D Appl. Phys., 2004, 37(9), p R86-R108

M. Bertagnolli, M. Marchese, G. Jacucci, I. StDoltsinis, and S. Noelting, Thermomechanical Simulation of the Splashing of Ceramic Droplets on a Rigid Substrate, J. Comput. Phys., 1997, 133(2), p 205-221

H.B. Parizi, L. Rosenzweig, J. Mostaghimi, S. Chandra, T. Coyle, H. Salimi, L. Pershin, A. McDonald, and C. Moreau, Numerical Simulation of Droplet Impact on Patterned Surfaces, J. Therm. Spray Technol., 2007, 16(5-6), p 713-721

M. Pasandideh-Fard, V. Pershin, S. Chandra, and J. Mostaghimi, Splat Shapes in a Thermal Spray Coating Process: Simulations and Experiments, J. Therm. Spray Technol., 2002, 11(2), p 206-217

G. Mauer, R. Vassen, and D. Stover, Atmospheric Plasma Spraying of Yttria-Stabilized Zirconia Coatings with Specific Porosity, Surf. Coat. Technol., 2009, 204(1-2), p 172-179

M.F. Morks and A. Kobayashi, Effect of Gun Current on the Microstructure and Crystallinity of Plasma Sprayed Hydroxyapatite Coatings, Appl. Surf. Sci., 2007, 253(17), p 7136-7142

A.N. Khan, J. Lu, and H. Liao, Effect of Residual Stresses on Air Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2003, 168(2-3), p 291-299

M. Friis, C. Persson, and J. Wigren, Influence of Particle In-flight Characteristics on the Microstructure of Atmospheric Plasma Sprayed Yttria Stabilized ZrO2, Surf. Coat. Technol., 2001, 141(2-3), p 115-127

L. Li, A. Vaidya, S. Sampath, H.B. Xiong, and L.L. Zheng, Particle Characterization and Splat Formation of Plasma Sprayed Zirconia, J. Therm. Spray Technol., 2006, 15(1), p 97-105

S. Alavi, M. Passandideh-Fard, and J. Mostaghimi, Simulation of Semi-molten Particle Impacts Including Heat Transfer and Phase Change, J. Therm. Spray Technol., 2012, 21(6), p 1278-1293

M. Fukumoto, D. Ohgitani, and T. Yasui, Effect of Substrate Surface Change on Flattening Behaviour of Thermal Sprayed Particles, Mater. Trans., 2004, 45(6), p 1869-1873

A.T.T. Tran, M.M. Hyland, K. Shinoda, and S. Sampath, Influence of Substrate Surface Conditions on the Deposition and Spreading of Molten Droplets, Thin Solid Films, 2011, 519(8), p 2445-2456

M. Fukumoto, E. Nishioka, and T. Matsubara, Effect of Interface Wetting on Flattening of Freely Fallen Metal Droplet onto Flat Substrate Surface, J. Therm. Spray Technol., 2002, 11(1), p 69-74

N.K. Myshkin, A.Y. Grigoriev, S.A. Chizhik, K.Y. Choi, and M.I. Petrokovets, Surface Roughness and Texture Analysis in Microscale, Wear, 2003, 254(10), p 1001-1009

L. Bianchi, A. Denoirjean, F. Blein, and P. Fauchais, Microstructural Investigation of Plasma-Sprayed Ceramic Splats, Thin Solid Films, 1997, 299(1-2), p 125-135

S. Sampath, X.Y. Jiang, J. Matejicek, A.C. Leger, and A. Vardelle, Substrate Temperature Effects on Splat Formation, Microstructure Development and Properties of Plasma Sprayed Coatings Part I: Case Study for Partially Stabilized Zirconia, Mater. Sci. Eng. A, 1999, 272(1), p 181-188

A.A. Syed, A. Denoirjean, B. Hannoyer, P. Fauchais, P. Denoirjean, A.A. Khan, and J.C. Labbe, Influence of Substrate Surface Conditions on the Plasma Sprayed Ceramic and Metallic Particles Flattening, Surf. Coat. Technol., 2005, 200(7), p 2317-2331

T.C. Hanson, C.M. Hackett, and G.S. Settles, Independent Control of HVOF Particle Velocity and Temperature, J. Therm. Spray Technol., 2002, 11(1), p 75-85

A. McDonald, C. Moreau, and S. Chandra, Effect of Substrate Oxidation on Spreading of Plasma-Sprayed Nickel on Stainless Steel, Surf. Coat. Technol., 2007, 202(1), p 23-33

M. Fukumoto and Y. Huang, Flattening Mechanism in Thermal Sprayed Nickel Particle Impinging on Flat Substrate Surface, J. Therm. Spray Technol., 1999, 8(3), p 427-432

M. Raessi, J. Mostaghimi, and M. Bussmann, Effect of Surface Roughness on Splat Shapes in the Plasma Spray Coating Process, Thin Solid Films, 2006, 506, p 133-135

M. Xue, S. Chandra, J. Mostaghimi, and H.R. Salimijazi, Formation of Pores in Thermal Spray Coatings Due to Incomplete Filling of Crevices in Patterned Surfaces, Plasma Chem. Plasma P, 2007, 27(5), p 647-657

M. Qu and A. Gouldstone, On the Role of Bubbles in Metallic Splat Nanopores and Adhesion, J Therm Spray Techn, 2008, 17(4), p 486-494

C.J. Li and J.L. Li, Evaporated-Gas-Induced Splashing Model for Splat Formation During Plasma Spraying, Surf. Coat. Technol., 2004, 184(1), p 13-23

H.B. Guo, H. Murakami, and S. Kuroda, Effect of Hollow Spherical Powder Size Distribution on Porosity and Segmentation Cracks in Thermal Barrier Coatings, J. Am. Ceram. Soc., 2006, 89(12), p 3797-3804

Acknowledgments

This work was jointly supported by the National Natural Science Foundations of China (NSFC) under the Grant No. 51202277 and Young Scholar Project (No. 12ZR1452000) supported by the Shanghai Science and Technology Committee. The current work was also supported by the Major Program for Basic Research of Shanghai Science and Technology Committee (Grant No. 12DJ1400402).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, D., Zhao, H., Zhong, X. et al. Effect of the Bond Coating Surface Morphology on Ceramic Splat Construction. J Therm Spray Tech 24, 1450–1458 (2015). https://doi.org/10.1007/s11666-015-0334-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0334-z