Abstract

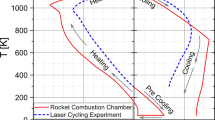

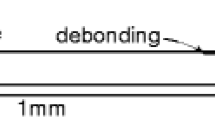

The lifetime of rocket combustion chambers can be increased by applying thermal barrier coatings. The standard coating systems usually used in gas turbines or aero engines will fail at the bond coat/substrate interface due to the chemical difference as well as the different thermal expansion between the copper liner and the applied NiCrAlY bond coat. A new bond coat alloy for rocket engine applications was designed previously with a chemical composition and coefficient of thermal expansion more similar to the copper substrate. Since a comparable material has not been applied by thermal spraying before, coating tests have to be carried out. In this work, the new Ni-30%Cu-6%Al-5%Cr bond coat alloy is applied via high velocity oxygen fuel spraying. In a first step, the influence of different coating parameters on, e.g., porosity, amount of unmolten particles, and coating roughness is investigated and a suitable parameter set for further studies is chosen. In a second step, copper substrates are coated with the chosen parameters to test the feasibility of the process. The high-temperature behavior and adhesion is tested with laser cycling experiments. The new coatings showed good adhesion even at temperatures beyond the maximum test temperatures of the NiCrAlY bond coat in previous studies.

Similar content being viewed by others

References

J.R. Riccius, O. Haidn, and E.B. Zametaev, Influence of Time Dependent Effects on the Estimated Life Time of Liquid Rocket Chamber Walls, AIAA, 2004.

L.U. Ogbuji, Oxidation Behavior of Cu-Cr Environmental Barrier Coatings on Cu-8Cr-4Nb, Surf. Coat. Technol., 2005, 197(2-3), p 327-335

S.V. Raj, L.J. Ghosn, C. Robinson, and D. Humphrey, High Heat Flux Exposures of Coated GRCop-84 Substrates, Mater. Sci. Eng. A, 2007, 457, p 300-312

J. Schloesser, M. Bäker, and J. Rösler, Laser Cycling and Thermal Cycling Exposure of Thermal Barrier Coatings on Copper Substrates, Surf. Coat. Technol., 2011, 206, p 1605-1608

T. Fiedler, T. Fedorova, J. Rösler, and M. Bäker, Design of a Nickel-Based Bond-Coat Alloy for Thermal Barrier Coatings on Copper Substrates, Metals, 2014, 4, p 503-518

B. Rajasekaran, G. Mauer, and R. Vaßen, Enhanced Characteristics of HVOF-Sprayed MCrAlY Bond Coats for TBC Applications, J. Therm. Spray Technol., 2011, 20, p 1209-1216

E. Lugscheider, C. Herbst, and L. Zhau, Parameter Studies on High-Velocity Oxy-fuel Spraying of MCrAlY Coatings, Surf. Coat. Technol., 1998, 108-109, p 16-23

K. Isoyama, J. Kawakita, S. Kuroda, and H. Yumoto, Key Factors for Dense Copper Coating by HVOF Spraying, Thermal Spray, ASM International, 2003, 2003, p 755-762

S. Bose, High Temperature Coatings, Elsevier, Amsterdam, 2007

S. Deshpande, S. Sampath, and H. Zhang, Mechanisms of Oxidation and its Role in Microstructural Evolution of Metallic Thermal Spray Coatings—Case Study for Ni-Al, Surf. Coat. Technol., 2006, 200, p 5395-5406

ImageJ, http://rsb.info.nih.gov/ij/index.html, 2015-06-09

C.-J. Li and W.-Y. Li, Effect of Sprayed Powder Particle Size on the Oxidation Behavior of MCrAlY Materials During High Velocity Oxygen-Fuel Deposition, Surf. Coat. Technol., 2003, 162, p 31-41

L. Pawlowski, Science and Engineering of Thermal Spray Coatings, Wiley, Hoboken, 2008

Acknowledgements

The financial support has been provided by the German Research Foundation (Deutsche Forschungsgemeinschaft—DFG) in the framework of the Sonderforschungsbereich Transregio 40, Teilprojekt D2.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fiedler, T., Rösler, J. & Bäker, M. Development of a CuNiCrAl Bond Coat for Thermal Barrier Coatings in Rocket Combustion Chambers. J Therm Spray Tech 24, 1480–1486 (2015). https://doi.org/10.1007/s11666-015-0325-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0325-0