Abstract

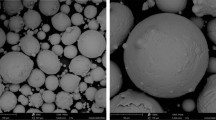

The use of Al-alloys for engine blocks production, instead of e.g., gray cast iron, results with weight savings and lower fuel consumption and therefore, reduces pollution. Possible solution for overcoming poor tribological properties of Al-alloys is the application of thermal spray coatings. In this paper, the tribological properties of two ferrous-based coatings were analyzed and compared with gray cast iron as a standard material for engine blocks. The process used for coating deposition on an Al-Si alloy substrate was atmospheric plasma spraying. In order to investigate the tribological behavior of these coatings under dominant adhesive and abrasive wear regime, two tests were applied with different test equipments and conditions. Both tribological tests showed that, for the investigated conditions, both coatings had improved wear resistance and lower coefficient of friction compared with gray cast iron.

Similar content being viewed by others

References

P. Ernst and B. Distler, Optimizing the cylinder running surface / piston system of internal combustion engines towards lower emissions, SAE Technical Paper 2012-32-0092, 2012.

C.M. Taylor, Automobile Engine Tribology: Design Considerations for Efficiency and Durability, Wear, 1998, 221(1), p 1-8

A. Rac and A. Vencl, Tribological Coatings on Aluminium Alloys Used in Engine Cylinder Bore-Piston System, Mobility & Vehicles Mechanics (MVM), 2004, 30(Special Ed.), p 105-113

A. Vencl and A. Rac, New Wear Resistant Al Based Materials and Their Application in Automotive Industry, Mobility & Vehicles Mechanics (MVM), 2004, 30(Special Ed.), p 115-139

G. Barbezat and R. Herber, Breakthrough in Improving Car Engine Performance Through Coatings, Sulzer Tech. Rev., 2001, 2, p 8-11

A. Vencl, M. Mrdak, and I. Cvijović, Microstructures and Tribological Properties of Ferrous Coatings Deposited by APS (Atmospheric Plasma Spraying) on Al-Alloy Substrate, FME Trans., 2006, 34(3), p 151-157

J. Dohmen, F.G. Hermsen, and G. Barbezat, Untersuchungen an plasmabeschichteten Zylinderlaufflächen, Mot. Z., 2004, 65(3), p 204-208

U. Sauerwein, H. Hick, R. Gosch, F.J. Feikus, R. Jakobs, and M. Müller, Cylinder Running Surfaces for Aluminium Diesel Engines, MTZ Worldwide, 2002, 63(6), p 28-33

M. Ford and M. Fisher, Method for coating combustion engine cylinders by plasma transferred wire arc thermal spray coating, 2010, p 1–10.

A. Vencl, Ferrous-based coatings for engine cylinder bores made of aluminium alloys: Tribological properties, Proceedings of International Conference on Materials, Tribology, Recycling: MATRIB 2011, Vela Luka (Croatia), 29.06-01.07.2011, p 527–535.

ISO 6621-3:2000 Internal Combustion Engines—Piston Rings—Part 3: Material Specifications, 2000.

A. Vencl, N. Manić, V. Popovic, and M. Mrdak, Possibility of the Abrasive Wear Resistance Determination with Scratch Tester, Tribol. Lett., 2010, 37(3), p 591-604

L. Deters, Reibung, Verschleiß und Schmierung, Konstruktionselemente des Maschinenbaus 2, W. Steinhilper and B. Sauer, Ed., Springer, Berlin, 2008, p 3-68

A.R. Riahi and A.T. Alpas, Wear Map for Grey Cast Iron, Wear, 2003, 255(1–6), p 401-409

A. Edrisy, T. Perry, and A.T. Alpas, Wear Mechanism Maps for Thermal-Spray Steel Coatings, Metall. Mater. Trans. A, 2005, 36(10), p 2737-2750

H.J. Verbeek, Tribological Systems and Wear Factors, Wear, 1979, 56(1), p 81-92

K. Kato and K. Adachi, Wear Mechanisms, Chap. 7, Modern Tribology Handbook, B. Bhushan, Ed., CRC Press, Boca Raton, 2001,

A. Rac, Basics of Tribology, Faculty of Mechanical Engineering, University of Belgrade, Belgrade, 1991, p 7–23 (in Serbian).

L. Prchlik and S. Sampath, Effect of the Microstructure of Thermally Sprayed Coatings on Friction and Wear Response Under Lubricated and Dry Sliding Conditions, Wear, 2007, 262(1–2), p 11-23

S. Usmani and S. Sampath, Time-Dependent Friction Response of Plasma-Sprayed Molybdenum, Wear, 1999, 225–229(2), p 1131-1140

S.F. Wayne, S. Sampath, and V. Anand, Wear Mechanisms in Thermally Sprayed Mo-Based Coatings, Tribol. Trans., 1994, 37(3), p 636-640

M. Van Driessche, Ferrography, Texaco Technology Ghent, Ghent, 2001

A. Milanti, H. Koivuluoto, P. Vuoristo, G. Bolelli, F. Bozza, and L. Lusvarghi, Microstructural Characteristics and Tribological Behavior of HVOF-Sprayed Novel Fe-Based Alloy Coatings, Coatings, 2014, 4(1), p 98-120

A. Vencl, B. Gligorijević, B. Katavić, B. Nedić, and D. Džunić, Abrasive Wear Resistance of the Iron- and WC-Based Hardfaced Coatings Evaluated With Scratch Test Method, Tribol. Ind., 2013, 35(2), p 123-127

M.G. Gee, Low Load Multiple Scratch Tests of Ceramics and Hard Metals, Wear, 2001, 250(1–12), p 264-281

Y. Xie and H.M. Hawthorne, The Damage Mechanisms of Several Plasma-Sprayed Ceramic Coatings in Controlled Scratching, Wear, 1999, 233–235, p 293-305

Acknowledgment

This work has been performed as a part of activities within the projects TR 34028 and TR 35021. These projects are supported by the Republic of Serbia, Ministry of Education, Science and Technological Development, whose financial help is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vencl, A. Tribological Behavior of Ferrous-Based APS Coatings Under Dry Sliding Conditions. J Therm Spray Tech 24, 671–682 (2015). https://doi.org/10.1007/s11666-014-0202-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0202-2