Abstract

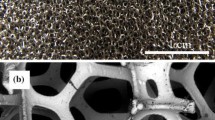

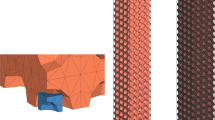

Metallic foam core sandwich structures have been of particular interest for engineering applications in recent decades because of their unique mechanical and physical properties. Thermal spraying techniques have been recently introduced as a novel low-cost method for production of these structures with complex shapes. One of the potential applications of the metallic foam core sandwich structures prepared by thermal spray techniques is as heat shield devices. Open porosity in the microstructure of the coating may allow the cooling efficiency of the heat shield to be improved through the film cooling phenomenon. A modified twin wire-arc spraying process was employed to deposit high temperature resistant alloy 625 coatings with a high percentage of the open porosity. The effect of skin porosity on the mechanical properties (flexural rigidity) of the sandwich structures was studied using a four-point bending test. It was concluded from the four-point bending test results that increase in the porosity content of the coatings leads to decrease in the flexural rigidity of the sandwich panels. The ductility of the porous and conventional arc-sprayed alloy 625 coatings was improved after heat treatment at 1100 °C for 3 h.

Similar content being viewed by others

References

J. Banhart, Manufacture, Characterisation and Application of Cellular Metals and Metal Foams, Prog. Mater Sci., 2001, 46(6), p 559-632

J. Banhart and W. Brinkers, Fatigue Behavior of Aluminum Foams, J. Mater. Sci. Lett., 1999, 8, p 617-619

H.R. Salimijazi, L. Pershin, T.W. Coyle, J. Mostaghimi, and S. Chandra, Metal Foam Sandwich Structure as a High Temperature Heat Exchanger, 2008 International Thermal Spray Conference & Exposition, Vol 1, 2008

F. Azarmi, T.W. Coyle, and J. Mostaghimi, Evaluation of the Flexural Rigidity of Sandwich Structures Using Experimentally Obtained Mechanical Properties of the Constituents, J. Therm. Spray Technol., 2009, 19(1-2), p 429-438

F. Azarmi, T.W. Coyle, and J. Mostaghimi, Flexural Properties of Sandwich Beams Consisting of Air Plasma Sprayed Alloy 625 and Nickel Alloy Foam, J. Mater. Sci., 2009, 44(11), p 2836-2843

M. Swellam, S. Yi, M.F. Ahmad, and L.M. Huber, Mechanical Properties of Cellular Materials. I. Linear Analysis of Hexagonal Honeycombs, J. Appl. Polym. Sci., 1997, 63(3), p 383-393

A.G. Evans, J.W. Hutchinson, N.A. Fleck, M.F. Ashby, and H.N.G. Wadley, The Topological Design of Multifunctional Cellular Metals, Prog. Mater Sci., 2001, 46(3), p 309-327

H.R.S. Jazi, J. Mostaghimi, S. Chandra, L. Pershin, and T. Coyle, Spray-Formed, Metal-Foam Heat Exchangers for High Temperature Applications, J. Therm. Sci. Eng. Appl., 2009, 1(3), p 031008

F. Azarmi, J. Saaedi, T.W. Coyle, and J. Mostaghimi, Microstructure Characterization of Alloy 625 Deposited on Nickel Foam using Air Plasma Spraying, Adv. Eng. Mater., 2008, 10(5), p 459-465

S. Salavati, R. Rezaey, L. Pershin, T.W. Coyle, and J. Mostaghimi, Development of High Density Twin Wire Arc Sprayed Coatings on Metallic Foam Substrates, Proceedings of the International Thermal Spray Conference, 2013, pp 345-350

H.R. Salimijazi, J. Mostaghimi, L. Pershin, T.W. Coyle, and S. Chandra, Hydraulic Characteristics and Thermal Properties of Metal Foam Sandwich Structure for High Temperature Heat Exchanger Applications, International Thermal Spray Conference & Exposition, 2009, pp 535-540

H.R. Salimijazi, Spray Forming of Metal Foam Heat Exchangers, Proceedings of ITP2009, 2009

F. Azarmi, T. Coyle, J. Mostaghimi, and L. Pershin, A New Approach to Develop High Temperature Foam Core Sandwich Structures Using Air Plasma Spraying, Int. J. Adv. Manuf. Technol., 2009, 44(9-10), p 900-905

M. Arai and T. Suidzu, Porous Ceramic Coating for Transpiration Cooling of Gas Turbine Blade, J. Therm. Spray Technol., 2013, 22(5), p 690-698

F.T. Davidson, D.a. KistenMacher, and D.G. Bogard, Film Cooling With a Thermal Barrier Coating: Round Holes, Craters, and Trenches, J. Turbomach., 2013, 136(4), p 041007

F. Azarmi, T. Coyle, and J. Mostaghimi, Young’s Modulus Measurement and Study of the Relationship Between Mechanical Properties and Microstructure of Air Plasma Sprayed Alloy 625, Surf. Coatings Technol., 2009, 203(8), p 1045-1054

P. Callus and C. Berndt, Relationships Between the Mode II, Fracture Toughness and Microstructure of Thermal Spray Coatings, Surf. Coatings Technol., 1999, 114(2-3), p 114-128

S. Deshpande, A. Kulkarni, S. Sampath, and H. Herman, Application of Image Analysis for Characterization of Porosity in Thermal Spray Coatings and Correlation with Small Angle Neutron Scattering, Surf. Coatings Technol., 2004, 187(1), p 6-16

K. Kanny and H. Mahfuz, Flexural Fatigue Characteristics of Sandwich Structures at Different Loading Frequencies, Compos. Struct., 2005, 67(4), p 403-410

M. Styles, P. Compston, and S. Kalyanasundaram, The Effect of Core Thickness on the Flexural Behaviour of Aluminium Foam Sandwich Structures, Compos. Struct., 2007, 80(4), p 532-538

A. Lyckegaard, O.T. Thomsen, E. Bozhevolnaya, Advancing with Sandwich Structures and Materials, Proceedings of the 7th International Conference on Sandwich Structures, 2005, pp 29-31

S.S. Madaeni, M.E. Aalami-Aleagha, and P. Daraei, Preparation and Characterization of Metallic Membrane Using Wire Arc Spraying, J. Membr. Sci., 2008, 320(1-2), p 541-548

A. Belenky and D. Rittel, Static and Dynamic Flexural Strength of 99.5% Alumina: Relation to Porosity, Mech. Mater., 2012, 48, p 43-55

ASTM international, Standard Test Method for Flexural Properties of Sandwich Constructions, Annual Book of ASTM Standards, ASTM international, 2000

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2014 International Thermal Spray Conference, held May 21-23, 2014, in Barcelona, Spain, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Salavati, S., Pershin, L., Coyle, T.W. et al. Effect of Porosity Content of Arc-Sprayed Alloy 625 Skins on the Flexural Behavior of Nickel Foam Core Sandwich Structures. J Therm Spray Tech 24, 215–221 (2015). https://doi.org/10.1007/s11666-014-0177-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0177-z