Abstract

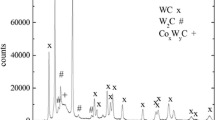

Currently, the determination of the mass loss is usually used for a quantitative evaluation of wear tests, while the analysis of wear tracks is utilized for a qualitative evaluation of wear. Both evaluation methods can only be used after the wear testing process and their results only present the final outcome of the wear test. However, the changes during the wear test and the time-dependent wear mechanisms are of great interest as well. A running wear test in a large chamber scanning electron microscope (SEM) offers the first opportunity to observe the wear process in situ. Different wear mechanisms, such as the adhesive, abrasive wear, surface fatigue and tribochemical reaction, can be recorded with high magnification. Within this research, a special pin-on-disk testing device is designed for a vacuum environment. Using this device, arc-sprayed NiCrBSi coatings and high-velocity-oxygen-fuel-sprayed WC-12Co coatings were tested in a large chamber SEM with Al2O3 ceramic balls as wear counterparts. During the wear testing, different wear mechanisms were determined and the processes were recorded in short video streams.

Similar content being viewed by others

References

F.-W. Bach, K. Möhwald, B. Drößler, and L. Engl, Technology and Potential of Wear Resistant Thermal Spray Coatings, Mat.-wiss. u. Werkstofftech., 2005, 36(8), p 353-359 [in German]

P. Heinrich and W. Krömmer, “Thermisches Spritzen - aktueller Stand der Technik und Zukunftsperspektiven,” Proceedings of Großen Schweißtechnischen Tagung, 2000, p 314-319 [in German]

B. Wielage, Entwicklungen und Trends in der thermischen Spritztechnik, Schriftenreihe: Werkstoffe und werkstofftechnische Anwendungen, 2000, 4, p 1-9

G. Bolelli, V. Cannillo, L. Lusvarghi, and T. Manfredini, Wear Behaviour of Thermally Sprayed Ceramic Oxide Coatings, Wear, 2006, 261(11-12), p 1298-1315

G. Sundararajan, K.U.M. Prasad, D.S. Rao, and S.V. Joshi, A Comparative Study of Tribological Behavior of Plasma and D-Gun Sprayed Coatings Under Different Wear Modes, J. Mater. Eng. Perform., 1998, 7(3), p 343-351

X.S. Xing and R.K.Y. Li, Wear Behavior of Epoxy Matrix Composites Filled with Uniform Sized Sub-micron Spherical Silica Particles, Wear, 2004, 256, p 21-26

W. Tillmann, I. Baumann, P. Hollingsworth, and L. Hagen, Sliding and Rolling Wear Behavior of HVOF Sprayed Coatings Derived from Conventional, Fine and Nanostructured WC-12Co Powders, J. Therm. Spray Technol., 2014, 23(1-2), p 262-280

H.J.C. Voorwaldb, R.C. Souzaa, W.L. Pigatinc, and M.O.H. Cioffi, Evaluation of WC-17Co and WC-10Co-4Cr Thermal Spray Coatings by HVOF on the Fatigue and Corrosion Strength of AISI, 4340 Steel, Surf. Coat. Technol., 2005, 190(2-3), p 155-164

J. Nurminen, J. Näkki, and P. Vuoristo, Microstructure and Properties of Hard and Wear Resistant MMC Coatings Deposited by Laser Cladding, Int. J. Rerfract. Met. Hard Mater., 2009, 27, p 472-478

B. Normand, V. Fervel, C. Coddet, and V. Nikitine, Tribological Properties of Plasma Sprayed Alumina-Titania Coatings: Role and Control of the Microstructure, Surf. Coat. Technol., 2000, 123, p 278-287

H. Chen, Z. Zhang, and C. Ding, Tribological Properties of Nanostructured Zirconia Coatings Deposited by Plasma Spraying, Wear, 2002, 253, p 885-893

W. Tillmann, W. Luo, and J. Nebel, Influence of the Carbide Feedstock Size on the Tribological Characteristics of Rolled and Ground FTC-FeCSiMn Coatings, Therm. Spray Bull., 2011, 4(1), p 56-63

W.G. Sundararajan, K.U.M. Prasad, D.S. Rao, and S.V. Joshi, A Comparative Study of Tribological Behavior of Plasma and D-Gun Sprayed Coatings under Different Wear Modes, J. Mater. Eng. Perform., 1998, 7(3), p 343-351

T. Mang, K. Bobzin, and Y. Bartels, Industrial Tribology, Tribosystems, Friction, Wear and Surface Engineering, Lubrication, Willey-VCH, Weinheim, 2011. ISBN 978-3-527-32057-8

H. Czichos and K. Habig, Tribologie-Handbuch, Tribometrie, Tribomaterialien. Tribotechnik, Vieweg + Teubner Verlag, Wiesbaden, 2010. ISBN 978-3-8348-9660-5

W. Tillmann, W. Luo, I. Baumann, P. Hollingsworth, B. Krebs, and L. Hagen, Optimization of Thermal Spray Coatings for Forming Tools, China Surf. Eng., 2012, 25(4), p 1-14

I. Baumann, “Highly Wear-Resistant and Near-Net-Shape Tool Surfaces by Means of High Velocity Oxygen Fuel Flame Spraying Techniques.” Dissertation, Technische Universitaet Dortmund, Vol 5, Vulkan-Verlag, Essen, Germany, 2012. ISBN 978-3-8027-8813-0

W. Tillmann, W. Luo, A.E. Tekkaya, and Z. Franzen, Wear Analysis of Rolled and Ground Iron-Based-Alloy-Coatings with and Without Hard Material Reinforcement, Mat.-wiss. u. Werkstofftech., 2012, 43(6), p 485-494

W. Tillmann and W. Luo, “Microstructure and Wear Resistance of Arc-Sprayed NiCrBSi Coatings After Remelting.” Proceedings of International Thermal Spray Conference, 2011, Hamburg, Germany, p 1451-1456

W. Tillmann, E. Vogli, I. Baumann, B. Krebs, and J. Nebel, Wear-Protective Cermet Coatings for Forming Tools, Mat.-wiss. u. Werkstofftech., 2010, 41(7), p 597-607

Acknowledgments

The authors gratefully acknowledge the financial support of the DFG (German Research Foundation) within the Collaborative Research Centre SFB 708, project C2.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2014 International Thermal Spray Conference, held May 21-23, 2014, in Barcelona, Spain, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Luo, W., Tillmann, W. & Selvadurai, U. In Situ Wear Test on Thermal Spray Coatings in a Large Chamber Scanning Electron Microscope. J Therm Spray Tech 24, 263–270 (2015). https://doi.org/10.1007/s11666-014-0163-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0163-5